Abstract

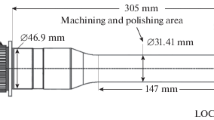

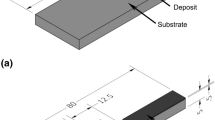

This study investigated the effects of surface texture in a compressor impeller shaft on its remanufacturing using high-velocity oxy-fuel (HVOF). Nine main types of surface texture were prepared. The HVOF system was used to remanufacture samples related to the appearance of these surface texture features, and the samples without texture were selected as the control group. The performance of remanufactured samples was evaluated by the scratch method. The effect of the surface texture factor level on first cracks that occurred (critical load LC1) was investigated using the analytic hierarchy process (AHP) method. The levels of various factors that influence the indicator weight, as well as the preferred combination, were determined. The representative cross-sectional morphologies and element distribution of the preferred coated samples were investigated using scanning electron microscopy (SEM) and elemental line scanning, respectively. Results indicate that the coating combined with the substrate mainly through a mechanical method, and adhesion strength was substantially improved via a suitable surface texture. It can be concluded that fabricating a suitable surface texture is an effective way to improve the coating adhesion strength of the shaft remanufactured using HVOF.

ᅟ

Similar content being viewed by others

References

Hao S, Wang H, Zhao L (2016) Surface modification of 40CrNiMo7 steel with high current pulsed electron beam treatment. Nucl Instrum Methods Phys Res Sect B Beam Interact Mater Atoms 368:81–85. doi:10.1016/j.nimb.2015.11.039

Sun J, Chen S, Qu Y, Li J (2015) Review on stress corrosion and corrosion fatigue failure of centrifugal compressor impeller. Chin J Mech Eng 28:217–225. doi:10.3901/CJME.2014.1210.178

Lei X, Huajun C, Hailong L, Yubo Z (2016) Study on laser cladding remanufacturing process with FeCrNiCu alloy powder for thin-wall impeller blade. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9445-z

Chang Y, Zhou D, Wang YL, Huang HH (2016) Repulsive interaction of sulfide layers on compressor impeller blades remanufactured through plasma spray welding. J Mater Eng Perform 25:5343–5351. doi:10.1007/s11665-016-2364-1

Aljuneidi T, Bulgak AA (2016) A mathematical model for designing reconfigurable cellular hybrid manufacturing-remanufacturing systems. Int J Adv Manuf Technol 87:1585–1596. doi:10.1007/s00170-016-9141-z

Macedo PB, Alem D, Santos M, Junior ML (2016) Hybrid manufacturing and remanufacturing lot-sizing problem with stochastic demand, return, and setup costs. Int J Adv Manuf Technol 82:1241–1257. doi:10.1007/s00170-015-7445-z

Hussain T, Dudziak T, Simms NJ, Nicholls JR (2013) Fireside corrosion behavior of HVOF and plasma-sprayed coatings in advanced coal/biomass Co-fired power plants. J Therm Spray Technol 22:797–807. doi:10.1007/s11666-013-9887-x

Thakur L, Arora N, Jayaganthan R, Sood R (2011) An investigation on erosion behavior of HVOF sprayed WC-CoCr coatings. Appl Surf Sci 258:1225–1234. doi:10.1016/j.apsusc.2011.09.079

Chen H, Gou G, Tu M, Liu Y (2009) Characteristics of nano particles and their effect on the formation of nanostructures in air plasma spraying WC-17Co coating. Surf Coat Technol 203:1785–1789. doi:10.1016/j.surfcoat.2008.12.023

Frazao J, Chandrashekhar S, Osman MOM, Sankar TS (1986) On the design and development of a new BTA tool to increase productivity and workpiece accuracy in deep hole machining. Int J Adv Manuf Technol 1:3–23. doi:10.1007/BF02601457

Rolleri A, Roffael E (2010) Influence of the surface roughness of particleboards and their performance towards coating. Maderas Ciency Tecnol 12:143–148. doi:10.4067/S0718-221X2010000200009

Zheng X, Tan J, Zhang Q, Wang M, Meng L (2017) Effect of laser surface texturing depth on the adhesion of electroless plated nickel coating on alumina. Surf Coat Technol 311:151–156. doi:10.1016/j.surfcoat.2017.01.002

Mohammadi Z, Ziaei-Moayyed AA, Mesgar ASM (2007) Grit blasting of Ti-6Al-4V alloy: optimization and its effect on adhesion strength of plasma-sprayed hydroxyapatite coatings. J Mater Process Technol 193:15–23. doi:10.1016/j.jmatprotec.2007.03.119

Ghabchi A, Sampath S, Holmberg K, Varis T (2014) Damage mechanisms and cracking behavior of thermal sprayed WC-CoCr coating under scratch testing. Wear 313:97–105. doi:10.1016/j.wear.2014.02.017

Pan ZY, Wang Y, Li XW, Wang CH, Zou ZW (2012) Effect of submicron and nano SiC particles on erosion wear and scratch behavior of plasma-sprayed Al2O3/8YSZ coatings. J Therm Spray Technol 21:995–1010. doi:10.1007/s11666-012-9800-z

Ordoobadi SM (2013) Application of AHP and Taguchi loss functions in evaluation of advanced manufacturing technologies. Int J Adv Manuf Technol 67:2593–2605. doi:10.1007/s00170-012-4676-0

Ayaǧ Z, Özdemir RG (2006) A fuzzy AHP approach to evaluating machine tool alternatives. J Intell Manuf 17:179–190. doi:10.1007/s10845-005-6635-1

Jiang XY, Lauke B, Beckert W, Schuller T (2001) Numerical simulation of micro-scratch tests for coating/substrate composites. Compos Interfaces 8:19–40. doi:10.1163/15685540052543638

Bravo-Bárcenas D, Campos-Silva I, Cimenoglu H, MartínezTrinidad J, FloresJiménez M, MartinezGutiérrez H (2016) Characterisation of CoB–Co2B coatings by the scratch test. Surf Eng 32:570–577. doi:10.1080/02670844.2015.1121315

Kreng VB, Wu CY, Wang IC (2011) Strategic justification of advanced manufacturing technology using an extended AHP model. Int J Adv Manuf Technol 52:1103–1113. doi:10.1007/s00170-010-2805-1

Khairy AB (2001) Aspects of surface and edge finish by magnetoabrasive particles. J Mater Process Technol 116:77–83. doi:10.1016/S0924-0136(01)00840-8

Ahrens M, Bleck W, Staudte J (2001) Surface conditioning by reactive gases during continuous annealing of sheet steel. J Mater Process Technol 117:270–275. doi:10.1016/S0924-0136(01)00778-6

Fauchais P, Vardelle M, Vardelle A, Bianchi L, Léger AC (1995) Parameters controlling the generation and properties of plasma sprayed zirconia coatings. Plasma Chem Plasma Process 16:S99–S125. doi:10.1007/BF01512630

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Zhou, D., Huang, H. et al. Effects of the surface texture in a compressor impeller shaft on its remanufacturing using HVOF. Int J Adv Manuf Technol 93, 2423–2432 (2017). https://doi.org/10.1007/s00170-017-0644-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0644-z