Abstract

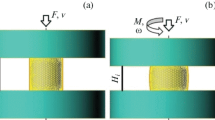

Torsional oscillation with a maximum frequency of 1.5 Hz was superposed with axial forging load to reduce the axial forging load in cold upsetting process. A cylindrical aluminum workpiece was twisted by rotating the lower die around the z-axis with a maximum alternating amplitude of 22.5° and a maximum angular speed of 0.5 rpm during cold upsetting process with a maximum compression speed of 0.1 mm/s. The torsional oscillation conditions for the load reduction were determined from theoretical and experimental results. It was found that the axial forging load was reduced by larger than 5% under the following conditions: rotation/compression speeds larger than approximately 15°/mm and torsion amplitudes larger than approximately 1°. A maximum reduction in the axial forging load of approximately 80% was obtained in upsetting with a rotation/compression speed with approximately 1700°/mm.

Similar content being viewed by others

References

Ohga K, Kondo K (1982) Research on precision die forging utilizing divided flow (1st report, theoretical analysis of processes utilizing flow relief-axis and relief-hole). Bulletin of JSME 25:1828–1835. doi:10.1299/jsme1958.25.1828

Osakada K, Mori K, Altan T, Groche P (2011) Mechanical servo press technology for metal forming. CIRP Ann Manuf Technol 60:651–672. doi:10.1016/j.cirp.2011.05.007

Kim SY, Tsuruoka K, Yamamoto T (2014) Effect of forming speed in precision forging process evaluated using CAE technology and high performance servo-press machine. Procedia Engineering 81:2415–2420. doi:10.1016/j.proeng.2014.10.343

Maeno T, Osakada K Mori K (2011) Reduction of friction in compression of plates by load pulsation. Int J Mach Tools Manuf 51:612–617. doi:10.1016/j.ijmachtools.2011.03.007

Bridgman PW (1943) On torsion combined with compression. J Appl Phys 14:273–283. doi:10.1063/1.1714987

Tekkaya AE, Becker C, Ortelt T, Grzancic G (2015) Utilizing stress superposition in metal forming. Proceedings of the 7th JSTP International Seminar on Precision Forging 1–6

Bridgman PW (1964) Studies in large plastic flow and fracture. Harvard University Press, Cambridge, pp 247–278. doi:10.4159/harvard.9780674731349

Yogo Y, Sawamura M, Hosoya M, Kamiyama M, Iwata N, Ishikawa T (2014) Measurement method for stress-strain curve in a super-large strain range. Mater Sci Eng A 600:82–89. doi:10.1016/j.msea.2014.02.026

Hansen BG, Bay N (1986) Two new methods for testing lubricants for cold forging. J Mech Work Technol 13:189–204. doi:10.1016/0378-3804(86)90065-3

Teller M, Seuren S, Bambach M, Hirt G (2015) A new compression-torsion-tribometer with scalable contact pressure for characterization of tool wear during plastic deformation. Conference Papers in Science Article ID 496515. doi:10.1155/2015/496515

Fujimori N (1969) Research on high-speed rotation forging method. Proceedings of the 20th Japanese Joint Conference for the Technology of Plasticity 221–224. (in Japanese)

Bochniak W, Korbel A (2003) KOBO type forming: forging of metals under complex conditions of the process. J Mater Process Technol 134:120–134. doi:10.1016/S0924-0136(02)01033-6

Bochniak W, Korbel A, Szyndler R, Hanarz R, Stalony-Dobrzanski F, Blaz L, Snarski P (2006) New forging method of bevel gears from structural steel. J Mater Process Technol 173:75–83. doi:10.1016/j.jmatprotec.2005.09.028

Węglarczyk S, Madej L, Hanarz R, Bochniak W, Szyndler R, Korbel A (2008) Validation of the numerical simulation of forging of gear-wheel in the reversible rotating die. Steel research international 79, Special Edition 789–796

Maciejewski J, Mróz Z (2008) An upper-bound analysis of axisymmetric extrusion assisted by cyclic torsion. J Mater Process Technol 206:333–344. doi:10.1016/j.jmatprotec.2007.12.061

Korbel A, Bochniak W, Ostachowski P, Błaż L (2011) Visco-plastic flow of metal in dynamic conditions of complex strain scheme. Metall Mater Trans A 42A:2881–2897. doi:10.1007/s11661-011-0688-x

Korbel A, Bochniak W (2013) Lüders deformation and superplastic flow of metals extruded by KOBO method. Philos Mag 93:1883–1913. doi:10.1080/14786435.2013.765977

Nadai A (1950) Theory of flow and fracture of solids, vol 1, second edn. McGraw-Hill Book Company, Inc, New York, pp 347–352

Osakada K, Mori K (1986) A study of buckling in upsetting by use of finite element method. CIRP Ann Manuf Technol 35:161–164. doi:10.1016/S0007-8506(07)61861-7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matsumoto, R., Kou, J. & Utsunomiya, H. Reduction in axial forging load by low-frequency torsional oscillation in cold upsetting. Int J Adv Manuf Technol 93, 933–943 (2017). https://doi.org/10.1007/s00170-017-0553-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0553-1