Abstract

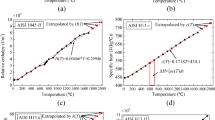

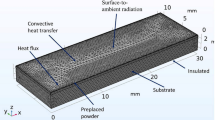

An uncoupled thermo-mechanical finite element model is developed to simulate the laser-cladding process of tungsten carbide (WC) on Inconel 718. First, a non-linear three-dimensional transient thermal model is developed, which calculates transient temperature distribution in the local clad area. Thermal load attributed to laser beam is implemented to the workpiece by using a developed subroutine. Thermal and mechanical material properties are introduced temperature dependent. All the major physical phenomena associated to the laser-cladding process, such as heat radiation, thermal conduction, and convection heat losses, are taken into account in the developed model. Subsequently, using the thermal history of the thermal analysis, a mechanical analysis is performed, from which the residual stresses are calculated. Both thermal and mechanical analysis results are verified through experimental works. Results show that the temperature profile and clad dimensions are strong function of the heat source and conductivity of material. It is concluded that the laser power and cladding velocity have significant effect on residual stresses. Also, it is found that the longitudinal stresses are approximately three times the transverse ones. Results of mechanical analysis reveal that by increasing input energy, residual stresses increase and number of cracks decreases in the cladded layer.

Similar content being viewed by others

References

Powell J, Henry PS, Steen WM (1988) Laser cladding with preplaced powder: analysis of thermal cycling and dilution effects. Surf Eng 4(2):141–149

Javid Y, Ghoreishi M, Torkamany MJ (2016) Laser cladding of WC onto Inconel 718 super alloy: parametric study and physical properties. Lasers Eng 34:353–369

Li G, Zhang M, Huang J, Sun Z, Wu Y (2015) A comparative study on microstructure and properties of Inconel 52 M overlays deposited by laser beam and GTA cladding. Int J Adv Manuf Technol 81(1):103–112

Farayibi PK, Abioye TE, Clare AT (2016) A parametric study on laser cladding of Ti-6Al-4V wire and WC/W2C powder. Int J Adv Manuf Technol 87(9):3349-3358

Popoola API, Fatoba OS, Aigbodion VS, Popoola OM (2016) Tribological evaluation of mild steel with ternary alloy of Zn-Al-Sn by laser deposition. Int J Adv Manuf Technol doi:10.1007/s00170-016-9170-7

Zhang YN, Cao X, Wanjara P (2013) Microstructure and hardness of fiber laser deposited Inconel 718 using filler wire. Int J Adv Manuf Technol 69(9):2569–2581

Javid Y, Ghoreishi M, Shamsaei S (2011) A three-dimensional heat transfer simulation of laser full penetration welding of Rene-80 super alloy. Lasers Eng 22:1–11

Mazumder J, Steen WM (1980) Heat transfer model for CW laser material processing. J Appl Phys 51(2):941–947

Jouvard JM, Grevey DF, Lemoine F, Vannes AB (1997) Continuous wave Nd:YAG laser cladding modeling: a physical study of track creation during low power processing. J Laser Appl 9(1):43–50

Yevko V, Park CB, Zak G, Coyle TW, Benhabib B (1998) Cladding formation in laser beam fusion of metal powder. Rapid Prototyp J 4(4):168–184

Kaplan AFH, Groboth G (2001) Process analysis of laser beam cladding. J Manuf Sci Eng Trans ASME 123(4):609–614

Toyserkani E, Khajepour A, Corbin S (2003) Three-dimensional finite element modeling of laser cladding by powder injection: effects of powder feed rate and travel speed on the process. J Laser Appl 15(3):153–160

Javid Y, Ghoreishi M (2012) Thermo-mechanical analysis of the laser welding of stainless steel 304. Lasers Eng 23:69–84

Gouge MF, Heigel JC, Michaleris P, Palmer TA (2015) Modeling forced convection in the thermal simulation of laser cladding processes. Int J Adv Manuf Technol 79(1):307–320

Sowdari D, Majumdar P (2010) Finite element analysis of laser irradiated metal heating and melting process. Opt Laser Technol 42:855–865

Lei YW, Sun R, Tang Y, Niu W (2012) Numerical simulation of temperature distribution and TiC growth kinetics for high power laser clad TiC/NiCrBSiC composite coatings. Opt Laser Technol 44:1141–1147

Hofman JT, Lange DF, Pathiraj B, Meijer J (2011) FEM modeling and experimental verification for dilution control in laser cladding. J Mater Process Technol 211(2):187–196

Tabernero I, Lamikiz A, Ukar E, Lacalle LN, Angulo C, Urbikain G (2010) Numerical simulation and experimental validation of powder flux distribution in coaxial laser cladding. J Mater Process Technol 210(15):2125–2134

Lei Y, Sun R, Tang Y, Niu W (2012) Numerical simulation of temperature distribution and TiC growth kinetics for high power laser clad TiC/NiCrBSiC composite coatings. Opt Laser Technol 44(4):1141–1147

Tseng WC, Aoh JN (2013) Simulation study on laser cladding on preplaced powder layer with a tailored laser heat source. Opt Laser Technol 48:141–152

Radaj D (1992) Heat effect of welding. Springer-Verlag, Berlin p 33

Carmignani C, Mares R, Toselli G (1999) Transient finite element analysis of deep penetration laser welding process in a single-pass butt-welded thick steel plate. Computa Methods Appl Mechanics Eng 179:197–214

Sun Y, Hao M (2012) Statistical analysis and optimization of process parameters in Ti6Al4V laser cladding using Nd:YAG laser. Opt Lasers Eng 50:985–995

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Javid, Y., Ghoreishi, M. Thermo-mechanical analysis in pulsed laser cladding of WC powder on Inconel 718. Int J Adv Manuf Technol 92, 69–79 (2017). https://doi.org/10.1007/s00170-017-0117-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0117-4