Abstract

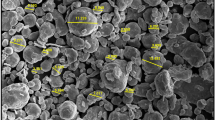

The sintering of 17-4PH stainless steel powder using microwaves has rarely been reported with results better than those produced by sintering with conventional resistive heating. This study evaluates the effect of the sintering temperature, holding time, heating rate and the pre-sintering stage in microwave-assisted sintering. By optimizing the sintering step to determine the optimal process, a more homogeneous microstructure, a greater sintered density, a greater shrinkage and better mechanical properties were obtained using microwave-assisted sintering. The total process time of the microwave-assisted sintering was notably less than conventional sintering, and the peak temperature was 150 to 200 °C lower. In 17-4PH stainless steel powder, microwave-assisted sintering was demonstrated to produce significantly better mechanical properties than conventional sintering. Measurements of the hardness distribution within the sintered specimen described the gradient of the mechanical properties of the microwave-sintered components. This study highlights why PM 17-4PH stainless steels should be produced using microwave-assisted sintering.

Similar content being viewed by others

References

Slaby SA, Kraft O, Eberl C (2016) Fatigue properties of conventionally manufactured and micro-powder-injection moulded 17-4 PH micro-components. Fatigue & Fracture of Engineering Materials & Structures 39:649–789

Ye H, Liu XY, Hong H (2008) Sintering of 17-4PH stainless steel feedstock for metal injection molding. Mater Lett 62:3334–3336

Sung HJ, Ha TK, Ahn S, Chang YW (2002) Powder injection moulding of a 17-4PH stainless steel and the effect of sintering temperature on its microstructure and mechanical properties. J Mater Process Techno 130-131:321–327

Jeefferie AR, Nurhashima S, Yuhazri MY, Sihombing H, Shukor SM, Abdullah NS, Omar MA (2011) Characterization of injection molded 17-4PH stainless steel prepared with waste rubber binder. Journal of Mechanical Engineering and Technology 3:11–21

Mutlu I, Oktay E (2011) Processing and properties of highly porous 17-4 PH stainless steel. Powder Metallurgy and Metal Ceramics 50:73–82

Suri P, Smarslok BP, German RM (2006) Impact properties of sintered and wrought 17-4 PH stainless steel. Powder Metall 49:40–47

Simchi A, Rota A, Imgrund P (2006) An investigation on the sintering behavior of 316L and 17-4PH stainless steel powders for graded composites. Mater Sci Eng A 424:282–289

Imgrund P, Rota A, Simchi A (2008) Microinjection moulding of 316L/17-4PH and 316L/Fe powders for fabrication of magnetic-nonmagnetic bimetals. J Mater Process Technol 200:259–264

Campañone LA, Paola CA, Mascheroni RH (2012) Modeling and simulation of microwave heating of foods under different process schedules. Food Bioprocess Technol 5:738–749

Menezes RR, Souto PM, Kiminami RHGA (2007) Microwave hybrid fast sintering of porcelain bodies. J Mater Process Technol 190:223–229

Leonelli C, Veronesi P, Denti L, Gatto A, Iuliano L (2008) Microwave assisted sintering of green metal parts. J Mater Process Technol 205:489–496

Charmond S, Carry CP, Bouvard D (2010) Densification and microstructure evolution of Y-tetragonal zirconia polycrystal powder during direct and hybrid microwave sintering in a single-mode cavity. J Eur Ceram Soc 30:1211–1221

Wu Q, Zhang X, Wu B, Huang W (2013) Effects of microwave sintering on the properties of porous hydroxyapatite scaffolds. Ceram Int 39:2389–2395

Chockalingam S, Earl DA (2010) Microwave sintering of Si3N4 with LiYO2 and ZrO2 as sintering additives. Mater Des 31:1559–1562

Chockalingam S, Traver HK (2010) Microwave sintering of β-SiAlON-ZrO2 composites. Mater Des 31:3641–3646

Bykov Y, Egorov S, Eremeev A, Kholoptsev V, Plotnikov I, Rybakov K, Semenov V, Sorokin A (2010) Effects of microwave heating in nanostructured ceramic materials. Powder Metallurgy and Metal Ceramics. 49:31–41

Chandrasekaran S, Basak T, Ramanathan S (2011) Experimental and theoretical investigation on microwave melting of metals. J Mater Process Technol 211:482–487

Srinath MS, Sharma AK, Kumar P (2011) A new approach to joining of bulk copper using microwave energy. Mater Des 32:2685–2694

Panda SS, Singh V, Upadhyaya A, Agrawal D (2006) Sintering response of austenitic (316L) and ferritic (434L) stainless steel consolidated in conventional and microwave furnaces. Scr Mater 54:2179–2183

Bose A, Agrawal D, Dowding RJ (2004) Preliminary investigations into microwave processing of powder injection molded 17-4 PH stainless steel. International Conference on Powder Metallurgy and Particulate Materials 53

Quinard C, Song J, Barriere T, Gelin JC (2011) Elaboration of PIM feedstocks with 316L fine stainless steel powders for the processing of micro-components. Powder Technol 208:383–389

Mariappan R, Kumaran S, Rao TS (2009) Effect of sintering atmosphere on structure and properties of austeno-ferritic stainless steels. Mater Sci Eng A 517:328–333

Oliveira FAC, Marcelo T, Alves C, Santos M, Mascarenhas J, Trindade B (2014) Effect of particle size of starting oxide powders on the performance of doped-lanthanum oxyapatite produced by mechanical alloying followed by microwave sintering. Adv Powder Technol 25: 1455–1461

Ertugrul O, Park H-S, Onel K, Willert-Porada M (2014) Effect of particle size and heating rate in microwave sintering of 316L stainless steel. Powder Technol 253:703–709

Shi JJ, Cheng Z, Gelin JC, Barriere T, Liu B Multi-physic coupling and full cycle simulation of microwave sintering, The Advances in Materials and Processing Technologies, AMPT 2015 Conference, December 14–17 2015, Madrid, Spain, In Symposium: New Trends in Powder Metallurgy, 1–6

Shi JJ (2014) Experiment and simulation of micro-injection molding and microwave sintering, [Co-tutorial PhD Thesis]: Chengdu&Besancon: Southwest Jiaotong University & Franche-Comte University

Song J, Gelin JC, Barriere T, Liu B (2006) Experiments and numerical modelling of solid state sintering for 316L stainless steel components. J Mater Process Technol 177:352–355

Yang RB, Liang WF, Lou CW, Lin JH (2012) Electromagnetic and microwave absorption properties of magnetic stainless steel powder in 2-18 GHz. J Appl Phys 111:07A338

Bahadoor A, Wang Y, Afsar MN (2005) Complex permittivity and permeability of barium and strontium ferrite powders in X, KU, and K-band frequency ranges. J Appl Phys 97:105–107

Kong X, Barriere T, Gelin JC (2012) Determination of critical and optimal powder loadings for 316L fine stainless steel feedstocks for micro-powder injection molding. J Mater Process Technol 212:2173–2182

Quinard C, Barriere T, Gelin JC (2009) Development and property identification of 316L stainless steel feedstock for PIM and μPIM. Powder Technol 190:123–128

Enneti RK, Shivashankar TS, Park SJ, German RM, Atre SV (2012) Master debinding curves for solvent extraction of binders in powder injection molding. Powder Technol 228:14–17

Nayer A (1997) The metals data book. McGraw-Hill, New York (NY)

Kim-Hak O, Soulier M, Szkutnik PD, Saunier S, Simon J, Goeuriot D (2012) Microwave sintering and thermoelectric properties of p-type (Bi0.2Sb0.8)2Te3 powder. Powder Technol 226:231–234

Chen YC, You HM (2015) Effect of sintering temperature on microstructures and microwave dielectric properties of Zn2SnO4 ceramics. Mater Chem Phys 154:94–99

Ma J, Diehl JF, Johnson EJ, Martin KR, Miskovsky NM, Smith CT, Weisel GJ, Weiss BL, Zimmerman DT (2007) Systematic study of microwave absorption, heating, and microstructure evolution of porous copper powder metal compacts. J Appl Phys 101:074906

Yoshikawa N (2010) Fundamentals and applications of microwave heating of metals. The Journal of Microwave Power and Electromagnetic Energy 44:4–13

Schönbauer BM, Yanase K, Endo M (2017) The influence of various types of small defects on the fatigue limit of precipitationhardened 17–4PH stainless steel. TheorAppl FractMech 87: 35–49

MPIF (2016) Materials standard for metal injection molded parts, MPIF standard 35. Metal Powder Industries Federation, Princeton, pp 19–19

Seerane M, Ndlangamandla P, Machaka R (2016) The influence of particle size distribution on the properties of metal injectionmoulded 17-4 PH stainless steel. J of the Southern Africa Institute of Mining and Metallurgy 116:935–940

Gulsoy HO, Ozgun O, Bilketay S (2016) A powder injection molding of Stellite 6 powder: sintering, microstructural and mechanical properties. Mater Sci Eng A 651:914–924

Gasko M, Rosenberg G (2011) Correlation between hardness and tensile properties in ultra-high strength dual phase steels.Mater Eng 18:155–159

Shen Y, Chawla N (2001) On the correlation between hardness and tensile strength in particle reinforced metal matrix composites. Mater Sci Eng A 297:44–47

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, J., Cheng, Z., Gelin, J. et al. Sintering of 17-4PH stainless steel powder assisted by microwave and the gradient of mechanical properties in the sintered body. Int J Adv Manuf Technol 91, 2895–2906 (2017). https://doi.org/10.1007/s00170-016-9960-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9960-y