This paper studies the influence of microwave heating on mass transport phenomena and phase transformations in nanostructured ceramic materials. Faster mass transport that depends significantly on the microwave field intensity is observed during microwave annealing of nanoporous alumina membranes. The effect of the microwave field on phase transformations and pore structure evolution in alumina powder compacts is characterized quantitatively. Preferred orientation of pores in ceramics sintered under linearly polarized microwave radiation is predicted theoretically and demonstrated experimentally. Decrease in the activation energy of plastic deformation is experimentally observed for alumina-based ceramics under microwave heating.

Similar content being viewed by others

References

Yu. V. Bykov, K. I. Rybakov, and V. E. Semenov, “High-temperature microwave processing of materials,” J. Phys. D: Appl. Phys., 34, R55–R75 (2001).

B. A. Wilson, K.-Y. Lee, and E. D. Case, “Diffusive crack-healing behavior in polycrystalline alumina: a comparison between microwave annealing and conventional annealing,” Mater. Res. Bull., 32, 1607–1616 (1997).

J. Wang, J. Binner, B. Vaidhyanathan, et al., “Evidence for the microwave effect during hybrid sintering,” J. Am. Ceram. Soc., 89, 1977–1984 (2006).

A. Birnboim, D. Gershon, J. Calame, et al., “Comparative study of microwave sintering of zinc oxide at 2.45, 30 and 83 GHz,” J. Am. Ceram. Soc., 81, 1493–1501 (1998).

A. G. Whittaker, “Diffusion in microwave-heated ceramics,” Chem. Mater., 17, 3426–3432 (2005).

S. V. Egorov, A. G. Eremeev, K. I. Rybakov, et al., “Microwave intensity-dependent mass transport enhancement in nanostructured alumina membranes,” in: D. C. Folz, J. H. Booske, D. E. Clark, et al. (eds.), Proc. 3rd World Cong. Microwave and Radio Frequency Applications, The American Ceramic Society, Westerville (2004), p. 167.

Yu. Bykov, A. Eremeev, M. Glyavin, et al., “24–84-GHz gyrotron systems for technological microwave applications,” IEEE Trans. on Plasma Science, 32, 67–72 (2004).

Yu. V. Bykov, S. V. Egorov, A. G. Eremeev, et al., “Evidence for microwave enhanced mass transport in the annealing of nanoporous alumina membranes,” J. Mater. Sci., 36, 131–136 (2001).

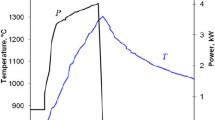

K. I. Rybakov, A. G. Eremeev, S. V. Egorov, et al., “Effect of microwave heating on phase transformations in nanostructured alumina,” J. Phys. D: Appl. Phys., 41, 102008 (2008).

K. I. Rybakov, A. G. Eremeev, S. V. Egorov, et al., “Phase transformations and pore structure evolution in nanostructured alumina under variable-power microwave heating,” in: Proc. Global Congress on Microwave Energy Applications, Japan Society of Electromagnetic Wave Energy Applications, Tokyo (2008), p. 241.

Yu. A. Kotov, “Electric explosion of wires as a method for preparation of nanopowders,” J. Nanoparticle Research, 5, 539–550 (2003).

V. Ivanov, S. Paranin, and A. Nozdrin, “Principles of pulsed compaction of ceramic nano-sized powders,” Key Eng. Mater., 132–136, 400–403 (1997).

R. A. Young (ed.), The Rietveld Method, Oxford University Press, Oxford (1993).

M. Willert-Porada, “A microstructural approach to the origin of “microwave effects” in sintering of ceramics and composites,” in: D. E. Clark et al. (eds.), Microwaves: Theory and Application in Materials Processing IV (Ceramic Transactions, Vol. 80), The American Ceramic Society, Westerville (1997), pp. 153–164.

K. I. Rybakov and V. E. Semenov, “Mass transport in ionic crystals induced by the ponderomotive action of high-frequency electric field,” Phys. Rev. B., 52, 3030–3033 (1995).

I. M. Lifshitz, A. M. Kossevich, and Ya. E. Geguzin, “Surface phenomena and diffusion mechanism of the movement of defects in ionic crystals,” J. Phys. Chem. Solids, 28, 783–798 (1967).

K. I. Rybakov, V. E. Semenov, G. Link, et al., “Preferred orientation of pores in ceramics under heating by a linearly polarized microwave field,” J. Appl. Phys., 101, 084915 (2007).

G. Link, M. Wolff, S. Takayama, et al., “Evidence for non-thermal effects during microwave sintering of zirconia ceramics,” in: A. G. Litvak (ed.), Proc. 6th Int. Workshop Strong Microwaves in Plasmas, Institute of Applied Physics, Nizhny Novgorod (2006), Vol. 2, pp. 722–726.

J. Tabellion and R. Clasen, “Electrophoretic deposition from aqueous suspensions for near-shape manufacturing of advanced ceramics and glasses––applications,” J. Mater. Sci., 39, 803–811 (2004).

S. V. Egorov, A. G. Eremeev, I. V. Plotnikov, et al., “Plastic deformation of ultrafine oxide ceramics under microwave heating,” Ross. Nanotekhnol., 3, No. 5–6, 9–12 (2008).

Yu. V. Bykov, A. G. Eremeev, S. V. Egorov, et al., Device for Sintering of a Ceramic Product Using Microwave Heating and External Pressure [in Russian], Russian Federation Patent No. 2352540 (2009).

W. R. Cannon and T. G. Langdon, “Creep of ceramics. Part 2: An examination of flow mechanisms,” J. Mater. Sci., 23, 1–20 (1988).

G. Bernard-Granger, C. Guizard, and R. Duclos, “Compressive creep behavior in air of a slightly porous assintered polycrystalline α-alumina material,” J. Mater. Sci., 42, 2807–2819 (2007).

O. Ruano, J. Wadsworth, and O. Sherby, “Deformation of fine-grained alumina by grain boundary sliding accommodated by slip,” Acta Mat., 51, 3617–3634 (2003).

A. Lakki, R. Schaller, C. Carry, et al., “High-temperature anelastic and viscoplastic deformation of finegrained magnesia- and magnesia/yttria-doped alumina,” J. Am. Ceram. Soc., 82, 2181–2187 (1999).

F. Wakai, T. Nagano, and T. Iga, “Hardening in creep of alumina by Zr segregation at grain boundary,” J. Am. Ceram. Soc., 80, 2361–2366 (1997).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 49, No. 1–2 (471), pp. 42–56, 2010.

Rights and permissions

About this article

Cite this article

Bykov, Y.V., Egorov, S.V., Eremeev, A.G. et al. Effects of microwave heating in nanostructured ceramic materials. Powder Metall Met Ceram 49, 31–41 (2010). https://doi.org/10.1007/s11106-010-9198-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-010-9198-4