Abstract

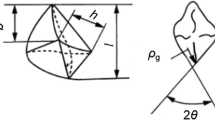

The machinability, including machined surface, edge quality, and the distribution of the subsurface residual stress, was studied during the orthogonal cutting of high-volume fraction SiCp/Al composites by both finite element analysis and experiments. The effect of cutting parameters on surface roughness, sizes of edge breakout, and residual stress were investigated. The elastic-plastic constitutive model and Johnson–Cook damage model for the Al alloy matrix, and the elastic-brittle failure for SiC particle were implemented in the mechanical properties of composites during the cutting simulation. The results indicate that the surface morphology is primarily dependent on the fracture models of SiC particles, and the formation of the negative shear plain is the main reason of edge breakout. Due to the inhomogeneity in the composites, the distribution of surface and subsurface residual stress is not uniform, and the high residual stress was distributed in the interface between irregular particles and matrix. The average value of residual stress of SiC particle is similar to that of the matrix. The predicted machined surface morphology and edge breakout sizes correlated well with the experimental observation. This study highlights the important role of the fracture model of SiC particles on surface finish and the edge quality. It provides useful information for better understanding of the mechanics in machining of the SiCp/Al composites.

Similar content being viewed by others

References

Liu J, Li J, Xu CY (2014) Interaction of the cutting tools and the ceramic-reinforced metal matrix composites during micro-machining: a review. CIRP J Manuf Sci Technol 7:55–70

Umanath K, Palanikumar K, Selvamani ST (2013) Analysis of dry sliding wear behaviour of Al6061/SiC/Al2O3 hybrid metal matrix composites. Compos Part B: Eng 53:159–168

Dandekar CR, Shin YC (2012) Modeling of machining of composite materials: a review. Int J Mach Tools Manuf 57:102–121

Davim JP (2011) Machining of metal matrix composites. Springer press, London

Warner AEM, Bell JAE, Stephenson TF (1998) Opportunities for new graphitic aluminium metal matrix composite. Mater Sci Technol 14:843–850

Kannan S, Kishawy HA, Deiab I (2009) Cutting forces and TEM analysis of the generated surface during machining metal matrix composites. J Mater Process Technol 209:2260–2269

Davim JP, Baptista AM (2000) Relationship between cutting force and PCD cutting tool wear in machining silicon carbide reinforced aluminium. J Mater Process Technol 103:417–423

Ge YF, Xu JH, Yang H, Luo SB, Fu YC (2008) Workpiece surface quality when ultra-precision turning of SiCp/Al composites. J Mater Process Techol 203:166–175

Palanikumar K, Karthikeyan R (2007) Assessment of factors influencing surface roughness on the machining of Al/SiC particulate composites. Mater Des 28:1584–1591

Gallab ME, Skallad M (1998) Machining of Al/SiC particulate metal matrix composites part II: work piece integrity. J Mater Process Technol 83:277–285

Ge YF, Xu JH, Yang H (2010) Diamond tools wear and their applicability when ultra-precision turning of SiCp/2009Al matrix composite. Wear 269:699–708

Yang YF, Wu Q, Zhan ZB, Li L, He N, Shrestha R (2015) An experimental study on milling of high-volume fraction SiCP/Al composites with PCD tools of different grain size. Int J Adv Manuf Technol 79:1699–1705

Davim JP (2002) Diamond tool performance in machining metal–matrix composites. J Mater Process Technol 128:100–105

Davim JP, Silva J, Baptista AM (2007) Experimental cutting model of metal matrix composites (MMCs). J Mater Process Technol 183:358–362

Dandekar CR, Shin YC (2013) Multi-scale modeling to predict sub-surface damage applied to laser-assisted machining of a particulate reinforced metal matrix composite. J Mater Process Technol 213:153–160

Zhu Y, Kishawy HA (2005) Influence of alumina particles on the mechanics of machining metal matrix composite during machining. Int J Mach Tools Manuf 45:389–398

Pramanik A, Zhang LC, Arsecularatne JA (2007) An FEM investigation into the behavior of metal matrix composites: tool-particle interaction during orthogonal cutting. Int J Mach Tools Manuf 47:1497–1506

Xiong YF, Wang WH, Jiang RS, Lin KY, Song GD (2016) Surface integrity of milling in-situ TiB2 particle reinforced Al matrix composites. Int J Refract Met Hard Mater 54:407–416

Fan XL, Suo T, Sun Q, Wang TJ (2013) Dynamic mechanical behavior of 6061 Al alloy at elevated temperatures and different strain rates. Acta Mech Solida Sin 26:111–120

Tan YQ, Yang DM, Sheng Y (2009) Discrete element method (DEM) modeling of fracture and damage in the machining process of polycrystalline SiC. J Eur Ceram Soc 29:1029–1037

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2016) On tool–workpiece interactions during machining metal matrix composites: investigation of the effect of cutting speed. Int J Adv Manuf Technol 84:2423–2435

Wang T, Xie LJ, Wang XB, Shang TY (2015) 2D and 3D milled surface roughness of high volume fraction SiCp/Al composites. Defence Technol 11:104–109

Zhou L, Hou N, Huang ST, Xu LF (2014) An experimental study on formation mechanisms of edge defects in orthogonal cutting of SiCp/Al composites. Int J Adv Manuf Technol 72:1407–1414

Zhang XX, Ni DR, Xiao BL, Andra H, Gan WM, Hofmannd M, Ma ZY (2015) Determination of macroscopic and microscopic residual stresses in friction stir welded metal matrix composites via neutron diffraction. Acta Mater 87:161–173

Dabade UA, Joshi SS, Balasubramaniam R, Bhanuprasad VV (2007) Surface finish and integrity of machined surfaces on Al/SiCp composites. J Mater Process Technol 192-193:166–174

Pramanik A, Zhang LC, Arsecularatne JA (2008) Machining of metal matrix composites: effect of ceramic particles on residual stress, surface roughness and chip formation. Int J Mach Tools Manuf 48:1613–1625

Salahshoor M, Guo YB (2014) Finite element simulation and experimental validation of residual stresses in high speed dry milling of biodegradable magnesium-calcium alloys. Int J Mech Sci 80:153–159

Arrazola PJ, Kortabarria A, Madariaga A, Esnaola JA, Fernandez E, Cappellini C, Ulutan D, Özel T (2014) On the machining induced residual stresses in IN718 nickel-based alloy: experiments and predictions with finite element simulation. Simul Model Pract Th 41:87–103

Capello E (2005) Residual stress in turning, part I: influence of process parameters. J Mater Process Technol 160:221–228

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, L., Cui, C., Zhang, P. et al. Finite element and experimental analysis of machinability during machining of high-volume fraction SiCp/Al composites. Int J Adv Manuf Technol 91, 1935–1944 (2017). https://doi.org/10.1007/s00170-016-9933-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9933-1