Abstract

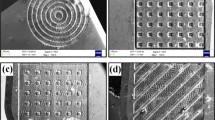

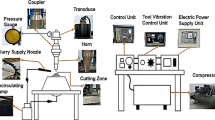

High-volume fraction SiCP/Al composites have attracted considerable interest as potential materials for electronic packaging. However, due to the existence of hard and brittle SiC particles, high-volume fraction SiCP/Al composite is a kind of difficult-to-machine materials. This paper presents an experimental study on milling high-volume fraction SiCP/Al composites with polycrystalline diamond tools of different grain sizes. A series of milling tests, under three sets of cutting parameters, were conducted on a Mikron UCP 710 high-speed milling machine center. Three polycrystalline diamond (PCD) tools with different grain sizes were used to mill straight grooves. The machined surface quality of the grooves, including surface topography and surface roughness, and tool wear characteristics were analyzed. The results showed that surface roughness increased with feed per tooth (f z) increasing from 5 to 10 μm/z. Chipping and abrasive wear can be observed in cutting tool and chipping is the dominant tool wear mechanism. Tool with grain size of 2~30 μm can achieve the best machined surface quality (Ra 0.3) under cutting parameters of f z = 5 μm/z, a p = 100 μm, and n = 10,000 rpm. But, it has the most severe tool wear in tool tip.

Similar content being viewed by others

References

Tomac N, Tannessen K, Rasch FO (1992) Machinability of particulate aluminium matrix composites. CIRP Ann Manuf Technol 41:55–58

Teti R (2002) Machining of composite materials. CIRP Ann Manuf Technol 51:611–634

Bian R, He N, Li L, Zhan ZB, Wu Q, Shi ZY (2014) Precision milling of high volume fraction SiCP/Al composites with monocrystalline diamond end mill. Int J Adv Manuf Technol 71:411–419

Zhou L, Huang ST, Wang D, Yu XL (2011) Finite element and experimental studies of cutting process of SiCP/Al composites with PCD tools. Int J Adv Manuf Technol 52:619–626

Jaffery SH, Khan M, Sheikh NA, Mativenga P (2013) Wear mechanism analysis in milling of Ti-6Al-4V alloy. Proc Inst Mech Eng B J Eng Manuf 227(8):1148–1156

Winert K (1993) A consideration of tool wear mechanism when machining metal matrix composites (MMC). CIRP Ann 42:95–98

Andrewes CJE, Feng HY, Lau WM (2000) Machining of an aluminum/SiC composite using diamond inserts. Mater Proc Technol 102:25–29

Pramanik A, Zhang LC, Aersecularatne JA (2008) Machining of metal matrix composites: effect of ceramic particles on residual stress, surface roughness and chip formation. Int J Mach Tools Manuf 48:1613–1625

Manna A, Bhattacharayya B (2003) A study on machinability of Al/SiC-MMC. J Mater Process Technol 140:711–716

Davim JP (2001) Turning particulate metal matrix composites: experimental study of the evolution the cutting forces, tool wear and workpiece surface roughness with the cutting time. Proc Inst Mech Eng B J Eng Manuf 215:371–376

Davim JP, Monteiro Baptista AP (2000) Relationship between cutting force and PCD cutting tool in machining silicon carbide reinforced aluminium. J Mater Process Technol 100:417–423

Huang ST, Zhou L, Yu XL, Cui Y (2012) Experimental study of high-speed milling of SiCP/Al composites with PCD tools. Int J Adv Manuf Technol 62:487–493

EI-Gallab M, Sklad M (1998) Machining of Al/SiC particulate metal-matrix composites. Part I: tool performance. Mater Proc Technol 83:151–158

El-Gallab M, Sklad M (1998) Machining of Al/SiC particulate metal matrix composites. Part II: workpiece surface integrity. J Mater Process Technol 83:277–285

El-Gallab M, Sklad M (2000) Machining of Al/SiC particulate metal matrix composites. Part III: comprehensive tool wear models. J Mater Process Technol 101:10–20

Muthukrishnan N, Murugan M, Prahlada Rao K (2008) Machinability issues in turning of Al-SiC (10p) metal matrix composites. Int J Adv Manuf Technol 39:211–218

Muthukrishnan N, Murugan M, Rao KP (2008) An investigation on the machinability of Al-SiC metal matrix composites using PCD inserts. Int J Adv Manuf Technol 38:447–454

Cheung CF, Chan KC, To S, Lee WB (2002) Effect of reinforcement in ultra-precision machining of Al6061/SiC metal matrix composites. Scr Mater 47:77–82

Cheung CF, Lee WB (2000) A theoretical and experimental investigation of surface roughness formation in ultra-precision diamond turning. Int J Mach Tools Manuf 40:979–1002

Wang T, Xie LJ, Wang XB, Jiao L, Shen JW, Xu H, Nie FM (2013) Surface integrity of high speed milling of Al/SiC/65p aluminum matrix composites. Procedia CIRP 8:475–480

Ge YF, Xu JH, Yang H (2010) Diamond tools wear and their applicability when ultra-precision turning of SiCp/2009Al matrix composite. Wear 269:699–708

Ge YF (2007) Fundamental research on ultra-precision turning of SiCP reinforced aluminum matrix composites. Ph.D Thesis, Nanjing University of Aeronautics and Astronautics, China (In Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Wu, Q., Zhan, Z. et al. An experimental study on milling of high-volume fraction SiCP/Al composites with PCD tools of different grain size. Int J Adv Manuf Technol 79, 1699–1705 (2015). https://doi.org/10.1007/s00170-015-6901-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6901-0