Abstract

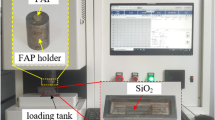

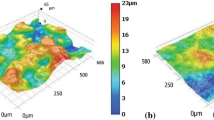

To obtain removal functions with high removal rate and stability in the polishing of hard and brittle material, an optical fabrication technology based on fixed abrasive diamond pellet (FADP) elasticity tool (ET) is designed. In this paper, we focus on the removal characteristics of ET, including removal profile, removal rate, stability of removal functions (RFs), and surface roughness. ET is analyzed theoretically about removal rate, stability, and fine surface adaptability. Modeling of the static influence function of ET based on finite element analysis (FEA) is proposed and fitted. A series of experiments are conducted to verify the effectiveness of the model. Within 640 min, the pellets could provide highly stable RFs with removal rate 1.71 mm3/min. In addition, the surface roughness about 43 nm is obtained.

Similar content being viewed by others

References

Wang Y, Lin B, Wang SL, Cao XY (2014) Study on the system matching of ultrasonic vibration assisted grinding for hard and brittle materials processing. Int J Mach Tools Manuf 77:66–73

Dong ZC, Cheng HB (2014) Study on removal mechanism and removal characters for SiC and fused silica by fixed abrasive diamond pellets. Int J Mach Tools Manuf 85:1–13

Witzendorff PV, Stompe M, Moalem A, Cvetkovic S, Suttmann O, Overmeyer L, Rissing L (2014) Dicing of hard and brittle materials with on-machine laser-dressed metal-bonded diamond blades. Precis Eng 38(1):162–167

Inasaki I (1987) Grinding of hard and brittle materials. CIRP Ann-Manuf Technol 36(2):463–471

Wang CJ, Yang W, Wang ZZ, Yang X, Sun ZJ, Zhong B, Pan R, Yang P, Guo YB, Xu Q (2014) Highly efficient deterministic polishing using a semirigid bonnet. Opt Eng 53(9):095102

Ke XL, Wang CJ, Guo YB, Xu Q (2016) Modeling of tool influence function for high-efficiency polishing. Int J Adv Manuf Technol 84(9):2479–2489

Wang CJ, Wang ZZ, Yang X, Sun ZJ, Peng YF, Guo YB, Xu Q (2014) Modeling of the static tool influence function of bonnet polishing based on FEA. Int J Adv Manuf Technol 74(1):341–349

Lv Z, Huang CZ, Zhu HT, Wang J, Wang Y, Yao P (2015) A research on ultrasonic-assisted abrasive water jet polishing of hard-brittle materials. Int J Adv Manuf Technol 78(5):1361–1369

Gagliardi JJ, Kim D, Sokol JJ, Zazzera LA, Romero VD, Atkinson MR, Nabulsi F, Zhang H (2013) A case for 2-body material removal in prime LED sapphire substrate lapping and polishing. J Manuf Process 15(3):348–354

Tam HY, Cheng HB, Wang YW (2007) Removal rate and surface roughness in the lapping and polishing of RB-SiC optical components. J Mater Process Technol 192–193:276–280

Luo SY, Chen KC (2009) An experimental study of flat fixed abrasive grinding of silicon wafers using resin-bonded diamond pellets. J Mater Process Technol 209(2):686–694

Cheng HB, Dong ZC, Ye X et al (2014) Subsurface damage of fused silica lapped by fixed-abrasive diamond pellets. Appl Opt 53(26):5841–5849

Yu GY, Walker DD, Li HY (2012) Implementing a grolishing process in Zeeko IRP machines. Appl Opt 51(27):6637–6641

Hee-Won J, Aoki T, Hatsuzawa T (2004) High-efficiency fixed abrasive polishing method for quartz crystal blanks. Int J Mach Tools Manuf 44(2–3):167–173

Tso PL, Ho SY (2007) Factors influencing the dressing rate of chemical mechanical polishing pad conditioning. Int J Adv Manuf Technol 33(7):720–724

Baisie E, Li ZC, Zhang XH (2013) Design optimization of diamond disk pad conditioners. Int J Adv Manuf Technol 66(9–12):2041–2052

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Wang, Z., Chen, S. et al. Investigation on removal features of fixed abrasive diamond pellets based on elasticity tool. Int J Adv Manuf Technol 91, 537–544 (2017). https://doi.org/10.1007/s00170-016-9726-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9726-6