Abstract

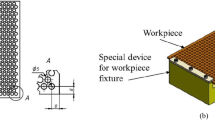

The aim of this work is to develop an experimental device useful to evaluate the friction coefficient in triangular thread joints (M12) manufactured with rolling and machining processes, and therefore, to relate precisely the clamping force to the tightening torque. Experimental static tests of clamp force during 10 tightening–loosening cycles were applied to specific threaded specimens obtained with the rolling and machining process. To analyze the mechanical and tribological behaviors of the manufactured threads, the torque coefficient (K) (nut factor), the average friction coefficient (μ m ), and the clamped force (F) have been evaluated during 10 cycles of tightening–loosening. The results of this study showed that the range of the variability of the torque coefficient and friction coefficient is between 0.151 and 0.54 and from 0.19 to 0.69 for the rolled thread, respectively. However, these coefficients are between 0.187 and 0.55 and from 0.25 to 0.72 for the machined thread, respectively. The clamping force preserves a linear relationship with the tightening torque and decreases as the number of tightening increases. The use of the rolling process to manufacture the thread joint can preserve a higher mechanical resistance and ameliorate the tribological behavior of the thread compared to the machining process.

Similar content being viewed by others

References

Liang D, Yuan SF (2015) Decision Fusion System for Bolted Joint Monitoring. Shock Vib 2015:11

Wrigley A (1995) Critical times for fastener firms. Am Met Market 103(63):4

Nassar SA, El-Khiami H, Barber GC, Zou Q, Sun TS (2005) An experimental study of bearing and thread friction in fasteners. J Tribol 127(2):263–272

Eliaz N, Gheorghiu G, Sheinkopf H, Levi O, Shemesh G, Ben-Mordechai A, Artzi H (2003) Failures of bolts in helicopter main rotor drive plate assembly due to improper application of lubricant. Eng Fail Anal 10(4):443–451

Croccolo D, De Agostinis M, Vincenzi N (2011) Failure analysis of bolted joints: effect of friction coefficients in torque–preloading relationship. Eng Fail Anal 18:364–373

Jiang Y, Zhang M, Park TW (2002) An experimental investigation on frictional properties of bolted joints. ASME Anal Bolted Joints 433:59–66

Sakai T (1978) The friction coefficient of fasteners. Bull JSME 213:33–40

Nassar SA, Ganeshmurthy S, Ranganathan RM, Barber GC (2007) Effect of tightening speed on the torque-tension and wear Pattern in Bolted Connections. J Press Vessel Technol 129(3):426–440

Nassar SA, Zaki AM (2009) Effect of Coating Thickness on the Friction Coefficients and Torque-Tension Relationship in Threaded Fasteners. J Tribol 131(2):021301

Elosegui I, Lopez de Lacalle LN (2011) Threading on ADI Cast Iron, Developing Tools and Conditions, In : International Conference On Advances In Materials And Processing Technologies (Ampt2010). AIP Publishing, 116–121

Sandvik Coromant. Metal Cutting Technical Guide

Fromentin G, Poulachon G, Moisan A (2002) Metallurgical aspects in cold forming tapping. NCMR Proceedings, Leeds, pp 373–377

Duan W, Joshi S (2011) Failure analysis of threaded connections in large-scale steel tie rods. Eng Fail Anal 18:2008–2018

Nassar SA, Matin PH, Barber GC (2005) Thread friction torque in bolted joints. ASME J Press Vessel Technol 127(4):387–393

Juvinall RC, Marshek KM (2000) Fundamentals of Machine Component Design, 3rd edn. Wiley, New York

Sacquepey D, Spenle D (1984) Precis de construction mecanique.3, calculs technologie et normalisation, 2emeth edn. AFNOR-Nathan (01), Paris, p 197

VDI 2230 (2003) Systematic calculation of high duty bolted joints-Joints with one cylindrical bolt

DIN 946, Determination of coefficient of friction of bolt–nut assemblies under specified conditions, Deutsche Norm, 1991

Eccles W, Sherrington I, Arnell RD (2010) Frictional changes during repeated tightening of zinc plated threaded fasteners. Tribol Int 43:700–707

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ibrahmi, A., Hbaieb, M. & Krichen, A. Experimental study of the effect of the threading process on the mechanical and tribological behaviors of the triangular thread. Int J Adv Manuf Technol 88, 269–276 (2017). https://doi.org/10.1007/s00170-016-8738-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8738-6