Abstract

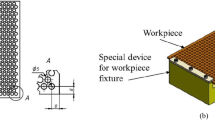

The principal aim of this work is the development of a specific experimental device used to identify the intrinsic characteristics of a thread and to characterize the influence of the tapping process. Two turns of thread engagement were only considered. The geometry of the tapping thread was visually inspected on a cross section of thread. Two tests of the screw-nut assembly were carried out. The first one that was used for analyzing the internal shear of thread consists in applying an axial displacement on the screw mounted on a fixed nut. In the second test, a tightening torque was applied on a pressure screw assembly to investigate principally the interface shear behavior of thread. Experiments revealed that the internal shear results in three-step spread over five distinct phases. The interface shear was quantified by the identification of the friction coefficient which was determined from the load-tightening torque relationship. The evolution of the friction coefficient versus the number of cycles of clamping/unclamping was also established. Therefore, the tribological behavior of each specimen was highlighted through thread wear analysis. The results and discussions are presented by comparing the cut and form triangular ISO thread and by studying the effect of the initial tap hole diameter.

Similar content being viewed by others

References

Fromentin G, Poulachon G, Moisan A, Julien B, Giessler J (2005) Precision and surface integrity of threads obtained by form tapping. CIRP Ann 54:519–522

Fromentin G, Bierla A, Minfray C, Poulachon G (2010) An experimental study on the effects of lubrication in form tapping. Tribology Int 43:1726–1734

Maciel D T, Filho SLMR, Lauro CH, Brandão LC (2015) Characteristics of machined and formed external threads in titanium alloy. Int J Adv Manuf Technol 79:779–792

de Oliveira JA, Filho SLMR, Brandao LC (2019) Investigation of the influence of coating and the tapered entry in the internal forming tapping process. Int J Adv Manuf Technol 101:1051–1063

Filho SLMR, de Oliveira JA, Arruda ÉM, Brandão LC (2016) Analysis of burr formation in form tapping in 7075 aluminum alloy. Int J Adv Manuf Technol 84:957–967

Masmoudi N, Soussi H, Krichen A (2017) Determination of an adequate geometry of the flanged hole to perform formed threads. Int J Adv Manuf Technol 92:547–560

Grimsmo E, Aalberg A, Langseth M, Clausen A (2016) Failure modes of bolt and nut assemblies under tensile loading. J Constr Steel Res 126:15–25

Hu Y, Shen L, Nie S, Yang B, Sha W (2016) Fe simulation and experimental tests of high-strength structural bolts under tension. J Constr Steel Res 126:174–186

Fransplass H, Langseth M, Hopperstad OS (2011) Tensile behaviour of threaded steel fasteners at elevated rates of strain. Int J Mech Sci 53:946–957

Fransplass H, Langseth M, Hopperstad O (2013) Numerical study of the tensile behaviour of threaded steel fasteners at elevated rates of strain. Int J Impact Eng 54:19–30

Duan W, Joshi S (2011) Failure analysis of threaded connections in large-scale steel tie rods. Eng Fail Anal 18:2008–2018

Wittke P, Walther F (2016) Cyclic deformation behavior of friction drilled internal threads in alsi10mg and az31 profiles. Procedia Structural Integrity 2:3264–3271

Ibrahmi A, Hbaieb M, Krichen A (2016) Experimental study of the effect of the threading process on the mechanical and tribological behaviors of the triangular thread. Int J Adv Manuf Technol 88:269–276

George ET (2006) Steel heat treatment: metallurgy and technologies. Steel treatment hand book, 352

Fernández Landeta J, Fernández Valdivielso A, López de Lacalle L, Girot F, Pérez Pérez J (2015) Wear of form taps in threading of steel cold forged parts. J Manuf Sci Eng 137(3):031002

Bull L, Palmiere EJ, Thackray RP, Burgess IW, Davison B (2015) Tensile behaviour of galvanised grade 8.8 bolt assemblies in fire. J. Struct Fire Eng 6(3):197–212

Hanus F, Zilli G, Franssen JM (2011) Behaviour of grade 8.8 bolts under natural fire conditions—tests and model. J Constr Steel Res 67(8):1292–1298

Yamanaka S, Amiya K, Saotome Y (2014) Effects of residual stress on elastic plastic behavior of metallic glass bolts formed by cold thread rolling. J Mater Process Technol 214(11):2593–2599

Sağlam H, Kuş R (2011) Performance of internal thread rolling head and the mechanical properties of rolled thread. In: 6th International Advanced Technologies Symposium (IATS’11), pp 16–18

Acknowledgments

This work is carried out thanks to the support and funding allocated to the Unit of Mechanical and Materials Production Engineering (UGPMM/UR17ES43) by the Tunisian Ministry of Higher Education and Scientific Research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Swissi, A., Soussi, H., Abid, M. et al. Internal and interface shear behaviors of cut and form tapping thread. Int J Adv Manuf Technol 105, 3463–3475 (2019). https://doi.org/10.1007/s00170-019-04519-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04519-y