Abstract

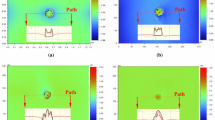

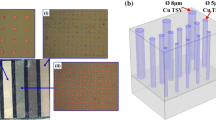

The demands of drilling on silicon wafers in multi-chip packages (MCPs) that employ laser ablation have increased. In this study, the bending fracture strengths of silicon specimens were experimentally measured using a four-point bending test after ablation with nanosecond and picosecond lasers. The specimens drilled with the picosecond laser showed a mean bending fracture strength (1530 MPa) higher than that of the specimens drilled with the nanosecond laser (678 MPa). One reason for this difference is that the cross-sectional roughnesses of the specimens drilled with the picosecond laser were less than those of the samples drilled with the nanosecond laser. Consequently, for the purpose of MCP interconnections, silicon wafer drilling with a picosecond laser is preferable to drilling with a nanosecond laser since the former yields greater bending fracture strength.

Similar content being viewed by others

References

Al-Sarawi SF, Abbott D, Franzon PD (1998) A review of 3-D packaging technology. IEEE Trans Compon, Packag Manuf Technol Part B 21(1):2–14

Hou TH, Chen SH, Lin TY, Huang KM (2005) An integrated system for setting the optimal parameters in IC chip-package wire bonding processes. Int J Adv Manuf Technol 30(3–4):247–253

Jang DM, Ryu C, Lee KY, Cho BH, Kim J, Oh TS, Lee WJ, Yu J (2007) Development and evaluation of 3-D SiP with vertically interconnected through silicon vias (TSV). IEEE Technol Compon Electron 57:847–852

Lee YH, Choi KJ (2010) Analysis of silicon via hole drilling for wafer level chip stacking by UV laser. Int J Precis Eng Manuf 11(4):501–507

Waits CM, Morgan B, Kastantin M, Ghodssi R (2005) Microfabrication of 3D silicon MEMS structures using gray-scale lithography and deep reactive ion etching. Sensors Actuators A Phys 119(1):245–253

Nagarajan R, Prasad K, Ebin L, Narayanan B (2007) Development of dual-etch via tapering process for through-silicon interconnection. Sensors Actuators A Phys 139(1–2):323–329

Alexey JC, Rodin M (2008) High throughput low CoO industrial laser drilling tool. Euro Asia Semicond 15:226–229

Tokarev VN, Lopez J, Lazare S (2000) Modelling of high-aspect ratio microdrilling of polymers with UV laser ablation. Appl Surf Sci 168(1–4):75–78

Pandey ND, Shan HS, Bharti A (2006) Percussion drilling with laser: hole completion criterion. Int J Adv Manuf Technol 28(9–10):863–868

Ren N, Jiang L, Liu D, Lv L, Wang Q (2014) Comparison of the simulation and experimental of hole characteristics during nanosecond-pulsed laser drilling of thin titanium sheets. Int J Adv Manuf Technol 76(5–8):735–743

Ganguly D, Acherjee B, Kuar AS, Mitra S (2012) Hole characteristics optimization in Nd:YAG laser micro-drilling of zirconium oxide by grey relation analysis. Int J Adv Manuf Technol 61(9–12):1255–1262

Shin D (2012) Effect of pulse interval on TSV process using a picosecond laser. J Laser Micro/Nanoeng 7(2):137–142

Luft A, Franz U, Emsermann L, Kaspar J (1996) A study of thermal and mechanical effects on materials induced by pulsed laser drilling. Appl Phys A Mater Sci Process 63(2):93–101

Shah L, Tawney J, Richardson M, Richardson K (2001) Femtosecond laser deep hole drilling of silicate glasses in air. Appl Surf Sci 183(3–4):151–164

Varel H, Ashkenasi D, Rosenfeld A, Wähmer M, Campbell EEB (1997) Micromachining of quartz with ultrashort laser pulses. Appl Phys A 373:367–373

Bruneau S, Hermann J, Dumitru G, Sentis M, Axente E (2005) Ultra-fast laser ablation applied to deep-drilling of metals. Appl Surf Sci 248(1–4):299–303

Juodkazis S, Okuno H, Kujime N, Matsuo S, Misawa H (2004) Hole drilling in stainless steel and silicon by femtosecond pulses at low pressure. Appl Phys A 79(4–6):1555–1559

Tan LS, Seet HL, Hong MH, Li XP (2009) Effects of femtosecond laser ablation on Vitrovac 6025X. J Mater Process Technol 209(9):4449–4452

Noh J, Lee JH, Na S, Lim H, Jung DH (2010) Fabrication of hierarchically micro- and nano-structured mold surfaces using laser ablation for mass production of superhydrophobic surfaces. Jpn J Appl Phys 49(10):106502

Schulze V, Weber P, Ruhs C (2012) Increase of process reliability in the micro-machining processes EDM-milling and laser ablation using on-machine sensors. J Mater Process Technol 212(3):625–632

Rieske R, Landgraf R, Wolter KJ (2009) Novel method for crystal defect analysis of laser drilled TSVs. IEEE Electron Compon Technol 59(1):1139–1146

Chichkov BN, Momma C, Nolte S, Alvensleben F, Tünnermann A (1996) Femtosecond, picosecond and nanosecond laser ablation of solids. Appl Phys A Mater Sci Process 63(2):109–115

Knowles MRH, Rutterford G, Karnakis D, Ferguson A (2007) Micro-machining of metals, ceramics and polymers using nanosecond lasers. Int J Adv Manuf Technol 33(1–2):95–102

Von der Linde D, Sokolowski-Tinten K (2000) The physical mechanisms of short-pulse laser ablation. Appl Surf Sci 154–155:1–10

Gamaly EG, Rode AV, Luther-Davies B, Tikhonchuk VT (2002) Ablation of solids by femtosecond lasers: ablation mechanism and ablation thresholds for metals and dielectrics. Phys Plasmas 9(3):949

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Noh, J., Kim, JH., Sohn, H. et al. Comparison of bending fracture strength of silicon after ablation with nanosecond and picosecond lasers. Int J Adv Manuf Technol 84, 2029–2036 (2016). https://doi.org/10.1007/s00170-015-7857-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7857-9