Abstract

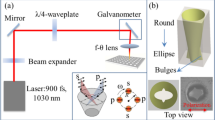

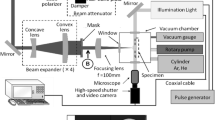

To reduce defects and improve the quality of laser drilling, the electric and magnetic (EM) field-assisted laser drilling has been tested. For different industrial applications, we performed microlaser drilling and macro-through-hole drilling under different EM fields using two different lasers (ns and ms). Drilling was performed on a custom apparatus that can produce static and rotating EM fields. The motion of the plasma strongly affected the drilling quality. In an EM field, both the ns and ms lasers produced holes with smaller diameters, better surface quality, and fewer hole wall defects. The drilling defects were mainly caused by the plasma-based multi-shock effect. The EM field can influence the motion of the plasma and minimize defects.

Similar content being viewed by others

References

Zhao K, Jia Z, Liu W, Ma J, Wang L (2014) Material removal with constant depth in CNC laser milling based on adaptive control of laser fluence. Int J Adv Manuf Technol. doi:10.1007/s00170-014- 6481-4

Low DKL, Li L, Corfe AG, Byrd PJ (2001) Spatter-free laser percussion drilling of closely spaced array holes. Int J Mach Tool Manuf 41:361–377

Low DKY, Li L, Corfe AG (2000) Effects of assist gas on the physical characteristics of spatter during laser percussion drilling of NIMONIC 263 alloy. Appl Surf Sci 154:689–695

Biswas R, Kuar AB, Sarkar S, Mitra S (2010) A parametric study of pulsed Nd:YAG laser micro-drilling of gamma-titanium aluminide. Opt Laser Technol 42:23–31

Stournaras A, Chryssolouris G (2010) On acoustic emissions in percussion laser drilling. Int J Adv Manuf Tech 46(5):611–620

Khan AH, Celotto S, Tunna L, O’Neill W, Sutcliffe CJ (2007) Influence of microsupersonic gas jets on nanosecond laser percussion drilling. Opt Laser Eng 45(6):709–718

Hsu J-C, Lin W-Y, Chang Y-J, Ho C-C, Kuo C-L (2015) Continuous-wave laser drilling assisted by intermittent gas jets. Int J Adv Manuf Tech 79(1):449–459

Krstulović N, Shannon S, Stefanuik R, Fanara C (2013) Underwater-laser drilling of aluminum. Int J Adv Manuf Tech 69(5):1765–1773

Zhang H, Xu J, Wang J (2009) Investigation of a novel hybrid process of laser drilling assisted with jet electrochemical machining. Opt Laser Eng 47(11):1242–1249

Walther K, Brajdic M, Kreutz EW (2008) Enhanced processing speed in laser drilling of stainless steel by spatially and temporally superposed pulsed nd:YAG laser radiation. Int J Adv Manuf Tech 35(9):895–899

Kruusing A (2004) Underwater and water-assisted laser processing: part 2—etching, cutting and rarely used methods. Opt Laser Eng 41(2):329–352

Wynne AE, Stuart BC (2003) Rate dependence of short-pulse laser ablation of metals in air and vacuum. Appl Phys A-mater 76(3):373–378

Curiel FF, García R, López VH, González-Sánchez J (2011) Effect of magnetic field applied during gas metal arc welding on the resistance to localised corrosion of the heat affected zone in AISI 304 stainless steel. Corros Sci 53(7):2393–2399

Li Y, Luo Z, Yan FY, Duan R, Yao Q (2013) Effect of external magnetic field on resistance spot welds of aluminum alloy. Mater Des 56:1025–1033

Liu YB, Sun QJ, Liu JP, Wang SJ, Feng JC (2015) Effect of axial external magnetic field on cold metal transfer welds of aluminum alloy and stainless steel. Mater Lett 152:29–31

OKUDA H, DAWSON JM (1973) Theory and numerical simulation on plasma diffusion across a magnetic field. Phys Fluids 16:408–426

Liang YH, Hu GY, Yuan P, Wang YL, Zhao B, Song FL, Lu QM, Zheng J (2015) Temporal evolutions of the plasma density and temperature of laser-produced plasma expansion in an external transverse magnetic field. Acta Phys Sin-Ch Ed 64(12)

Chen M, Li X, Liu L (2012) Effect of electric field on interaction between laser and arc plasma in laser-arc hybrid welding. IEEE T Plasma Sci 40(8):2045–2050

Ye C, Cheng GJ, Tao S, Wu BX (2013) Magnetic field effects on laser drilling. J Manuf Sci E-T Asme 135(6):61020

Chang YJ, Kuo CL, Wang NY (2012) Magnetic assisted laser micromachining for highly reflective metals. J Laser Micro Nanoen 7(3):254–259

Ho C-C, Tseng G-R, Chang Y-J, Hsu J-C, Kuo C-L (2014) Magnetic-field-assisted laser percussion drilling. Int J Adv Manuf Tech 73(1):329–340

Modest MF (2006) Effects of multiple reflections on hole formation during short-pulsed laser drilling. J Heat Trans-T Asme 128(7):653–661

Lu SCW, Shen Q, Zheng FX (2002) Laser irradiation effect. National Defense Industry Press, Beijing (in Chinese)

Francis F, Chen JP (2002) Lecture notes on principles of plasma processing. Plenum/Kluwer Publishers, New York

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lu, Y., Sun, G.F., Wen, D.P. et al. Effects of applying electric and magnetic fields on laser drilling. Int J Adv Manuf Technol 84, 2293–2300 (2016). https://doi.org/10.1007/s00170-015-7842-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7842-3