Abstract

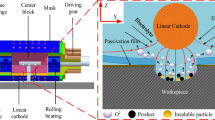

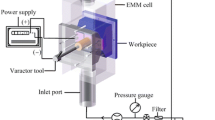

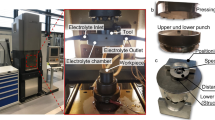

Electrochemical machining (ECM) is a powerful method to machine metals independently of their mechanical properties. Micro-sized structures can be formed with high precision. For this purpose, it is necessary to manufacture tools with adequately fine structures. Conventional ECM tools were manufactured by micro-drilling, -milling, -turning, etc. Depending on the complexity of the structures, these techniques are very elaborate and expensive. Recently, a new procedure, which combines photolithography and electroforming, the so-called PhoGaTool process (photolithographic electroforming of ECM tools), was published. In the present work, we demonstrate how this method can also be used for copying ECM tools that were conventionally manufactured. A copy of an industrial PECM tool (precise electrochemical machining) was manufactured and used for the structural characterization and determination of the replication accuracy. The electroforming parameters like deposition conditions, bath composition as well as physical and chemical parameters were optimized for model systems. The inclusion of bath additives in the metal matrix during the deposition leads to micro-stresses, hence in this contribution, an alternative additive-free electrolyte was used. The accuracy of the process was investigated by means of confocal laser scanning microscopy. Average deviations of the structure depth and the lateral structure dimensions are in the range of 5 %.

Similar content being viewed by others

References

Bannard J (1977) Electrochemical machining. J Appl Electrochem 7:1–29

McGeough JA (1974) Principles of electrochemical machining. Chapman and Hall Ltd, London

Datta M, Landolt D (1981) Electrochemical machining under pulsed current conditions. Electrochim Acta 26:899–907

Rajurkar KP, Kozak J, Wei B, McGeough JA (1993) Study of pulse electrochemical machining characteristics. CIRP Ann Manuf Technol 42:231–234

Bhattacharyya B, Malapati M, Munda J, Sarkar A (2007) Influence of tool vibration on machining performance in electrochemical micro-machining of copper. Int J Mach Tools Manuf 47:335–342

Rajurkar KP, Zhu D, McGeough JA, Kozak J, De Silva A (1999) New developments in electro-chemical machining. Ann CIRP 48(2):567–579

Weinmann M, Stolpe M, Busch R, Natter H (2015) Eletrochemical dissolution behaviour of Ti90Al6V4 and Ti60Al40 used for ECM applications. J Solid State Electrochem 19(2):485–495

Kozak J, Rajurkar KP, Makkar Y (2004) Selected problems of micro-electrochemical machining. J Mater Process Technol 149:426–431

Schuster R, Kirchner V, Allongue P, Ertl G (2000) Electrochemical micromachining. Science 289:98–101

Bhattacharyya B, Munda J, Malapati M (2004) Advancement in electrochemical micro-machining. Int J Mach Tools Manuf 44:1577–1589

Li XH, Wang ZL, Zhao WS, Hu FQ (2007) Pulsed micro-electrochemical machining technology. Key Eng Mater 339:327–331

Zhang Z, Wang Y, Chen F, Mao W (2011) A micro-machining system based on electrochemical dissolution of material. Russ J Electrochem 47:819–824

Leo Kumar SP, Jerald J, Kumanan S, Prabakaran R (2014) A review on current research aspects in tool-based micromachining processes. Mater Manuf Process 29:1291–1337

Fu WK, He N, Li L, Zhao M, Bian R (2014) Research on micromechanical drilling of micro-hole array in PVC mask. Mater Sci Forum 770:239–243

Asad ABMA, Masaki T, Rahman M, Lim HS, Wong YS (2007) Tool-based micro-machining. J Mater Process Technol 192–193:204–211

Rahman M, Asad ABMA, Wong YS (2014) Introduction to advanced machining technologies. Compr Mat Process 11:1–13

Tangwarodomnukun V, Likhitangsuwat P, Tevinpibanphan O, Dumkum C (2015) Laser ablation of titanium alloy under a thin and flowing water layer. Int J Mach Tools Manuf 89:14–28

Weinmann M, Weber O, Bähre D, Munief W, Saumer M, Natter H (2014) Photolithography-electroforming-pulse electrochemical machining: an innovative process chain for the high precision and reproducible manufacturing of complex microstructures. Int J Electrochem Sci 9:3917–3927

Natter H, Hempelmann R (2008) Nanocrystalline metals prepared by electrodeposition. Z Phys Chem 222:319–354

Natter H, Hempelmann R (2003) Tailor-made nanomaterials designed by electrochemical methods. Electrochim Acta 49:51–61

Fischer H (1973) Aspects of inhibition in electrodeposition of compact metals II. Effects of morphological interface inhibition. Electrodeposition Surf Treat 1(4):319–337

Hamann CH, Vielstich W (2005) Elektrochemie. Wiley-VCH, Weinheim

Puippe JC, Leaman F (1986) Theory and practice of pulse-plating. ASEF, Orlando

Vetter KJ, Bachmann KJ (1967) Zur Kristallisationsüberspannung. Z Phys Chem 53:9–28

Amblard J, Epelboin I, Froment M, Maurin G (1979) Inhibition and nickel electrocrystallization. J Appl Electrochem 9:233–242

Amblard J, Froment M, Maurin G, Mercier D, Trevisan-Pikacz E (1982) The electrocrystallization of nickel on vitreous carbon a kinetic and structural study of nucleation and coalescence. J Electroanal Chem Interfacial Electrochem 134(2):345–352

Amblard J, Froment M, Maurin G, Spyrellis N, Trevisan-Souteyrand E (1983) Nickel electrocrystallization—from nucleation to textures. Electrochim Acta 28:909–915

Amblard J, Froment M, Spyrellis N (1977) Origine des textures dans les depots electrolytiques de nickel. Surf Technol 5(3):205–234

Sathiyanarayanan S, Rajagopal G, Palaniswamy N, Raghavan M (2005) Corrosion protection by chemical vapor deposition: a review. Corros Rev 23(4–6):355–370

Helmersson U, Lattemann M, Bohlmark J, Ehiasarian AP, Gudmundsson JT (2006) Ionized physical vapor deposition (IPVD): a review of technology and applications. Thin Solid Films 513:1–24

Seah MP, Nunney TS (2010) Sputtering yields of compounds using argon ions. J Phys D Appl Phys 43:1–13

Larson C, Smith JR (2011) Recent trends in metal alloy electrolytic and electroless plating research: a review. T I Met Finish 6:333–341

Blink J, Farmer J, Choi J, Saw C (2009) Applications in the nuclear industry for thermal spray amorphous metal and ceramic coatings. Metall Mater Trans 40A:1344–1354

Moridi A, Hassani-Gangaraj SM, Guagliano M, Dao M (2014) Cold spray coating: review of material systems and future perspectives. Surf Eng 30(6):369–395

Natter H, Hempelmann R (1996) Nanocrystalline copper by pulsed electrodeposition: the effects of organic additives, bath temperature, and pH. J Phys Chem 100:19525–19532

Natter H, Schmelzer M, Löffler MS, Krill CE, Fitch A, Hempelmann R (2000) Grain-growth kinetics of nanocrystalline iron studied in situ by synchrotron real-time x-ray diffraction. J Phys Chem B 104:2467–2476

Warren BE, Averbach LE (1950) The effect of cold-work distortion on x-ray patterns. J Appl Phys 21:595–599

Warren BE, Averbach LE (1952) The separation of cold-work distortion and particle size broadening in x-ray patterns. J Appl Phys 23:497

Warren BE (1990) X-ray diffraction. Dover Publications, INC, New York

Krill CE III, Helfen L, Michels D, Natter H, Fitch A, Masson O, Birringer R (2001) Size-dependent grain-growth kinetics observed in nanocrystalline Fe. Phys Rev Lett 86(5):842–845

Dini JW (1993) Electrodeposition: the materials science of coatings and substrates. Noyes, Park Ridge

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Weißhaar, K., Weinmann, M., Jung, A. et al. Replication of microstructured tools for electrochemical machining applications. Int J Adv Manuf Technol 82, 197–209 (2016). https://doi.org/10.1007/s00170-015-7367-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7367-9