Abstract

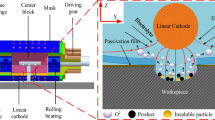

Surface geometrical features and their functionality depend on the manufacturing process which is employed for fabrication of surface structures. Maskless electrochemical micromachining (EMM) is used to generate various surface structures for diminishing and controlling friction and wear to increase the lifetime, reliability, and efficiency of mechanical systems. This paper presents a method for the generation of structured surfaces on stainless steel (SS-304) surfaces by using maskless EMM. The micropatterned tool is composed of 800 µm diameter circular holes in a 5 × 5 matrix form. The indigenously developed EMM set up consists of an EMM cell, electrical power supply system, and a controlled vertical cross-flow electrolyte circulation arrangement to control the influence of process parameters during the generation of the micro features of structured surfaces. The single structured cathode tool is used for the mass production of structured surfaces with a short fabrication time in the industrial context by avoiding the use of an individual masking process for each workpiece. The process has been characterized in terms of the effects of predominant process parameters such as machining voltage, electrolyte concentration, duty ratio, pulsed frequency, and machining time on the machined surface characteristics such as current efficiency, machining accuracy, and depth of the circular pattern on the stainless steel surfaces. A mathematical model is also developed to determine the theoretical depth of the dimple pattern and correlate the theoretical depths with actual depths as obtained by experimentation. Moreover, an effort has been made to study the structuring characteristics on the basis of micrographs obtained during the EMM.

Similar content being viewed by others

References

Bruzzone AAG, Costa HL, Lonardo PM (2008) Advances in engineered surfaces for functional performance. CIRP Ann Manuf Technol 57:750–769

Silk EA, Kim J, Kiger K (2006) Spray cooling of enhanced surfaces: impact of structured surface geometry and spray axis inclination. Int J Heat Mass Transf 49:4910–4920

Hintze W, Essen A, Wurfels K (1998) Tool for material-removing machining. US Patent 5:510–520

Evans CJ, Bryan JB (1999) Structured, textured or engineered surfaces. CIRP Ann Manuf Technol 4:541–556

Sen M, Shan HS (2005) A review of electrochemical macro- to micro-hole drilling processes. Int J Mach Tools Manuf 45:137–152

Li L, Diver C, Atkinson J (2006) Sequential laser and EDM micro drilling for next generation fuel injection nozzle manufacture. Ann CIRP 55:179–182

Nouraei S, Roy S (2008) Electrochemical process for micropattern transfer without photolithography: a modeling analysis. J Electrochem Soc 155(2):D97–D103

Zhu D, Qu NS, Li HS (2009) Electrochemical micro-machining of microstructures of micro hole and dimple array. CIRP Ann Manuf Technol 58:177–180

Munda J, Bhattacharyya B (2008) Investigation into electrochemical micromachining (EMM) through response surface methodology based approach. Int J Adv Manuf Technol 35:821–832

Rajurkar KP, Zhu D, Mcgeough JA (1999) New developments in electro-chemical machining. Ann CIRP 48:567–579

Datta M, Landolt D (2000) Fundamental aspects and applications of electrochemical micro-fabrication. Electrochim Acta 45:2535–2558

Wang Q, Zhu D (2005) Virtual texturing: modeling the performance of lubricated contacts of engineered surfaces. J Tribol Trans ASME 127:722–728

Wang X, Kato K (2003) Improving the anti-seizure ability of SiC seal in water with RIE texturing. Tribol Lett 14:275–280

Bhattacharyya B (2015) Electrochemical micromachining for nanofabrication, MEMS and nanotechnology. William Andrew Applied Science Publishers, Massachusetts, p 270

Acknowledgements

Authors acknowledge the financial support from the CAS phase–IV program, University Grants Commission, New Delhi, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kunar, S., Bhattacharyya, B. Investigation on surface structuring generated by electrochemical micromachining. Adv. Manuf. 5, 217–230 (2017). https://doi.org/10.1007/s40436-017-0186-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-017-0186-5