Abstract

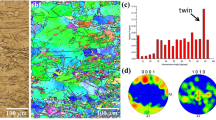

In this work, a new water bath friction stir spot welding (WB-FSSW) process was developed. The effects of dwell time on the microstructures and mechanical properties of the WB-FSSW-welded AZ31 magnesium alloy joints were investigated by microstructural observation, tensile tests, and microhardness tests. It was found that compared with those of ordinary FSSW welds, the WB-FSSW welds have poorer tensile shear force, almost equal tensile shear strength per unit area τ and higher microhardness mainly due to the narrower bonded zone width of the hooks and microstructures in the welded joints, respectively. Moreover, with the increase in the dwell time, the microhardness and the tensile shear strengthen per unit area τ of the WB-FSSW-welded joints increased firstly and then decreased because of the fluctuant evolution of grain size of α-Mg and the volume fraction of the β-Mg17All2. The optimal dwell time for the WB-FSSW welding was from 10 to 15 s whereby the finest grains and the highest mechanical properties of the welded joints can be achieved.

Similar content being viewed by others

References

Salahshoor M, Guo YB (2013) Process mechanics in ball burnishing biomedical magnesium–calcium alloy. Int J Adv Manuf Technol 302:133–144

Kulekci MK (2008) Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol 39:851–865

Kojima Y (2000) Project of platform science and technology for advanced magnesium alloys. Mater Trans JIM 42:1154–1159

Cao P, Qian M, David H, John S (2006) Effect of manganese on grain refinement of Mg-Al based alloys. Scr Mater 54:1853–1858

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding—process, weldment structure and properties. Prog Mater Sci 53:980–1023

Çam G (2011) Friction stir welded structural materials: beyond Al-alloys. Int Mater Rev 56:1–48

Çam G, Mıstıkoğlu S (2014) Recent developments in friction stir welding of Al-alloys. J Mater Eng Perform 23:1936–1953

Rajakumar S, Razalrose A, Balasubramanian V (2013) Friction stir welding of AZ61A magnesium alloy. Int J Adv Manuf Technol 68:277–292

Padmanaban G, Balasubramanian V (2010) An experimental investigation on friction stir welding of AZ31B magnesium alloy. Int J Adv Manuf Technol 49:111–121

Abdolahzadeh A, Omidvar H, Safarkhanian MA, Bahrami M (2014) Studying microstructure and mechanical properties of SiC-incorporated AZ31 joints fabricated through FSW: the effects of rotational and traveling speeds. Int J Adv Manuf Technol 75:1189–1196

Sato YS, Shiota A, Kokawa H, Okamoto K, Yang Q, Kim (2010) Effect of interfacial microstructure on lap shear strength of friction stir spot weld of aluminium alloy to magnesium alloy. Sci Technol Weld Join 15:319–324

Chandra T, Ionescu M, Mantovani D (2011) Preliminary investigation on friction spot welding of AZ31 magnesium alloy. Mater Sci Forum 706–709:3016–3021

Lin YC, Liu JJ, Lin BY, Lin CM, Tsai HL (2011) Effects of process parameters on strength of Mg alloy AZ61 friction stir spot welds. Mater Des 35:350–357

Karthikeyan R, Balasubramanian V (2010) Predictions of the optimized friction stir spot welding processparameters for joining AA2024 aluminum alloy using RSM. Int J Adv Manuf Technol 51:173–183

Badarinarayan H, Yang Q, Zhu S (2009) Effect of tool geometry on static strength of friction stir spot-welded aluminum alloy. Int J Mach Tools Manuf 49:142–148

Shen J, Min D, Wang D (2011) Effects of heating process on the microstructures and tensile properties of friction stir spot welded AZ31 magnesium alloy plates. Mater Des 32:5033–5037

Shen J, Wen L, Luo X, Xu N, Wang D, Liu M (2014) Development of novel heating tool friction stirspot welding (HT-FSSW) for AZ31 magnesiumalloy. Sci Technol Weld Join 19:369–375

Mofid MA, Abdollah-zadeh A, Malek Ghaini F (2012) The effect of water cooling during dissimilar friction stir welding of Al alloy to Mg alloy. Mater Des 36:161–167

Chandima Ratnayake RM, Brevika VA (2014) Experimental investigation of underwater stud friction stir welding parameters. Mater Manuf Process 29:1219–1225

Asadi P, Besharati Givi MK, Parvin N, Araei A, Taherishargh M, Tutunchilar S (2012) On the role of cooling and tool rotational direction on microstructure and mechanical properties of friction stir processed AZ91. Int J Adv Manuf Technol 63:987–997

James A, North TH, Thorpe SJ (2011) Localized corrosion of friction stir spot welds in magnesium AZ31 alloy. ECS Trans

Bohlen J, Yi SB, Swiostek J, Letzig D, Brokmeier HG, Kainer KU (2005) Microstructure and texture development during hydrostatic extrusion of magnesium alloy AZ31. Mater Sci Eng A 53:259–264

Liu LM, Dong CF (2006) Gas tungsten-arc filler welding of AZ31 magnesium alloy. Mater Lett 60:2194–2197

Song X, Ke LM, Xing L, Liu FC, Huang CP (2014) Effect of plunge speeds on hook geometries and mechanical properties in friction stir spot welding of A6061-T6 sheets. Int J Adv Manuf Technol 71:2003–2010

Jonckheere C, Meester BD · Cassiers C, Delhaye M, Simar A (2012) Fracture and mechanical properties of friction stir spot welds in 6063-T6 aluminum alloy. Int J Adv Manuf Technol 62:569–575

Su P, Gerlich A, North TH, Bendzsak GJ (2007) Intermixing in dissimilar friction stir spot welds. Metall Mater Trans A 38:584–595

Park SH, Sato YS, Kokawa H (2003) Microstructural evolution and its effect on Hall–Petchrelation ship in friction stirwelding of thixomolded Mg alloy AZ91D. J Mater Sci 38:4379–4383

Mitlin D, Radmilovic V, Pan T, Chen J, Feng Z, Santella ML (2006) Structure-properties relations in spot friction welded (also known as friction stir spot welded) 6111 aluminum. Mater Sci Eng A A441:79–96

Cizek L, Gregera M, Pawlicaa L, Dobrzanskib LA, Tanskib T (2004) Study of selected properties of magnesium alloy AZ91 after heat treatment and forming. Int J Mater Prod Technol 157–158:466–471

Yamamoto M, Gerlich A, North TH, Shinozaki K (2007) Mechanism of cracking in AZ91 friction stir spot welds. Sci Technol Weld Join 12:208–216

Bozkurt Y, Salman S, Çam G (2013) The effect of welding parameters on lap-shear tensile properties of dissimilar friction stir spot welded AA5754-H22/2024-T3 joints. Sci Technol Weld Join 18:337–345

Somekawa H, Hirai K, Watanabe H, Takigawa Y, Higashi K (2005) Dislocation creep behavior in Mg–Al–Zn alloys. Mater Sci Eng A 407:53–61

Su CW, Lu L (2006) A model for the grain refinement mechanism in equal channel angular pressing of Mg alloy from microstructural studies. Mater Sci Eng A 434:227–236

Heilmaier M, Saage H, Mirpuri KJ, Eckert J, Schultz L, Singh P (2002) Superposition of grain size and dispersion strengthening in ODS L12–(Al, Cr)3Ti. Mater Sci Eng A 329–331:106–111

Nie JF (2003) Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys. Scr Mater 48:1009–1015

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, X., Shen, J., Gong, F. et al. Effects of dwell time on the microstructures and mechanical properties of water bath friction stir spot-welded AZ31 magnesium alloy joints. Int J Adv Manuf Technol 82, 75–83 (2016). https://doi.org/10.1007/s00170-015-7361-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7361-2