Abstract

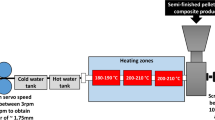

The joinability of different rigid thermoplastic polymers with aluminium AA6082-T6 alloy sheets by mechanical clinching is investigated. The polymers were heated using a convective source prior of clinching. Experimental tests were conducted by varying die geometry and pre-heating time. The joinability window for different thermoplastic polymers including polystyrene (PS), polycarbonate (PC) and poly(methyl methacrylate) (PMMA) was determined. The mechanical behaviours of clinched connections were assessed by means of single lap shear tests. To understand the effect of process parameters on the mechanical behaviours of clinched joints, dimensional analysis was also carried out. It was turned out that mechanical clinching could be successfully employed for joining thermoplastic polymer sheets with aluminium sheets being characterized by a very short processing time and producing high strength joints as compared to competitive technologies. The formability of the aluminium alloy and the toughness of the polymer component are crucial for the success of the process. However, even materials with reduced formability were joined by modifying conveniently the pre-heating time and die geometry.

Similar content being viewed by others

References

Grujicic M, Sellappan V, Arakere G, Seyr N, Obieglo A, Erdmann M, Holzleitner J (2008) The potential of a clinch-lock polymer metal hybrid technology for use in load-bearing automotive components. J Mater Eng Perform 18(7):893–902

Amancio-Filho ST, dos Santos JF (2009) Joining of polymers and polymer–metal hybrid structures: Recent developments and trends. Polym Eng Sci 49(8):1461–1476

Grujicic M, Sellappan V, He T, Seyr N, Obieglo A, Erdmann M, Holzleitner J (2008) Total life cycle-based materials selection for polymer metal hybrid body-in-white automotive components. J Mater Eng Perform 18(2):111–128

Meschut G, Janzen V, Olfermann T (2014) Innovative and highly productive joining technologies for multi-material lightweight car body structures. J Mater Eng Perform 23:1515–1523

Liu FC, Liao J, Nakata K (2014) Joining of metal to plastic using friction lap welding. Mater Des 54:236–244

Goushegir SM, dos Santos JF, Amancio-Filho ST (2014) Friction spot joining of aluminum AA2024/carbon-fiber reinforced poly(phenylene sulfide) composite single lap joints: microstructure and mechanical performance. Mater Des 54:196–206

Lambiase F, Paoletti A, Di Ilio A (2015) Mechanical behaviour of friction stir spot welds of polycarbonate sheets. The International Journal of Advanced Manufacturing Technology:in Press

He X, Gu F, Ball A (2014) A review of numerical analysis of friction stir welding. Prog Mater Sci 65:1–66

Huang Z, Sugiyama S, Yanagimoto J (2013) Hybrid joining process for carbon fiber reinforced thermosetting plastic and metallic thin sheets by chemical bonding and plastic deformation. J Mater Process Technol 213(11):1864–1874

Bartczak B, Mucha J, Trzepieciński T (2013) Stress distribution in adhesively-bonded joints and the loading capacity of hybrid joints of car body steels for the automotive industry. Int J Adhes Adhes 45:42–52

He X, Zhao L, Yang H, Xing B, Wang Y, Deng C, Gu F, Ball A (2014) Investigations of strength and energy absorption of clinched joints. Comput Mater Sci 94:58–65

Balawender T, Sadowski T, Golewski P (2012) Numerical analysis and experiments of the clinch-bonded joint subjected to uniaxial tension. Comput Mater Sci 64:270–272

He X (2011) A review of finite element analysis of adhesively bonded joints. Int J Adhes Adhes 31(4):248–264

Jiang T, Liu Z-X, Wang P-C (2014) Effect of aluminum pre-straining on strength of clinched galvanized SAE1004 steel-to-AA6111-T4 aluminum. J Mater Process Technol 215:193–204

Mucha J, Kaščák L, Spišák E (2013) The experimental analysis of forming and strength of clinch riveting sheet metal joint made of different materials. Adv Mech Eng 2013:1–11

Abe Y, Mori K, Kato T (2012) Joining of high strength steel and aluminium alloy sheets by mechanical clinching with dies for control of metal flow. J Mater Process Technol 212(4):884–889

Gerstmann T, Awiszus B (2014) Recent developments in flat-clinching. Comput Mater Sci 81:39–44

Lambiase F, Di Ilio A (2015) Mechanical clinching of metal–polymer joints. J Mater Process Technol 215:12–19

Lüder S, Härtel S, Binotsch C, Awiszus B (2014) Influence of the moisture content on flat-clinch connection of wood materials and aluminium. J Mater Process Technol 214:2069–2074

Lee C-J, Lee J-M, Ryu H-Y, Lee K-H, Kim B-M, Ko D-C (2014) Design of hole-clinching process for joining of dissimilar materials – Al6061-T4 alloy with DP780 steel, hot-pressed 22MnB5 steel, and carbon fiber reinforced plastic. J Mater Process Technol 214:2169–2178

Lambiase F (2013) Influence of process parameters in mechanical clinching with extensible dies. Int J Adv Manuf Technol 66(9–12):2123–2131

Neugebauer R, Kraus C, Dietrich S (2008) Advances in mechanical joining of magnesium. CIRP Ann Manuf Technol 57(1):283–286

Hirsch J (2014) Recent development in aluminium for automotive applications. Trans Nonferrous Metals Soc China 24(7):1995–2002

Mucha J (2011) The analysis of rectangular clinching joint in the shearing test. Maint Reliab 3:45–50

Lambiase F, Di Ilio A (2013) Optimization of the clinching tools by means of integrated FE modeling and Artificial intelligence techniques. Procedia CIRP 12:163–168

Lambiase F, Di Ilio A, Paoletti A (2015) Joining aluminium alloys with reduced ductility by mechanical clinching. Int J Adv Manuf Technol 77(5–8):1295–1304

Abe Y, Kato T, K-i M, Nishino S (2014) Mechanical clinching of ultra-high strength steel sheets and strength of joints. J Mater Process Technol 214:2112–2118

He X, Zhang Y, Xing B, Gu F, Ball A (2015) Mechanical properties of extensible die clinched joints in titanium sheet materials. Materials & Design

Xing B, He X, Wang Y, Yang H, Deng C (2015) Study of mechanical properties for copper alloy H62 sheets joined by self-piercing riveting and clinching. J Mater Process Technol 216:28–36

Lambiase F, Di Ilio A (2013) Finite element analysis of material flow in mechanical clinching with extensible dies. J Mater Eng Perform 22(6):1629–1636

Lambiase F, Di Ilio A (2014) An experimental study on clinched joints realized with different dies. Thin-Walled Struct 85:71–80

Wen T, Wang H, Yang C, Liu LT (2014) On a reshaping method of clinched joints to reduce the protrusion height. Int J Adv Manuf Technol 71:1709–1715

Mucha J (2011) The analysis of lock forming mechanism in the clinching joint. Mater Des 32(10):4943–4954

Coppieters S, Lava P, Baes S, Sol H, Van Houtte P, Debruyne D (2012) Analytical method to predict the pull-out strength of clinched connections. Thin-Walled Struct 52:42–52

Mucha J, Witkowski W (2014) The clinching joints strength analysis in the aspects of changes in the forming technology and load conditions. Thin-Walled Struct 82:55–66

Xu F, Zhao SD, Han XL (2014) Use of a modified Gurson model for the failure behaviour of the clinched joint on Al6061 sheet. Fatigue Fract Eng Mater Struct 37(3):335–348

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lambiase, F. Joinability of different thermoplastic polymers with aluminium AA6082 sheets by mechanical clinching. Int J Adv Manuf Technol 80, 1995–2006 (2015). https://doi.org/10.1007/s00170-015-7192-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7192-1