Abstract

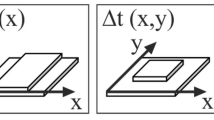

In order to help meet the needs of automotive original equipment manufacturers and their suppliers for a cost-effective, robust, reliable polymer-metal-hybrid (PMH) technology which can be used for the manufacturing of load-bearing body-in-white (BIW) components and which is compatible with the current BIW manufacturing process chain, a new approach, the so-called direct-adhesion PMH technology, was recently proposed (Grujicic et al., J. Mater. Process. Technol., 2008, 195, p 282-298). Within this approach, the necessary level of polymer-to-metal mechanical interconnectivity is attained through direct adhesion and mechanical interlocking. In the present work, a new concept for mechanical interlocking between the metal and plastics is proposed and analyzed computationally. The approach utilizes some of the ideas used in the spot-clinching joining process and is appropriately named clinch-lock PMH technology. To assess the potential of the clinch-lock approach for providing the required level of metal/polymer mechanical interlocking, a set of finite-element based sheet-metal forming, injection molding and structural mechanics analyses was carried out. The results obtained show that stiffness and buckling resistance levels can be attained which are comparable with those observed in the competing injection overmolding PMH process but with an ~3% lower weight (of the polymer subcomponent) and without the need for holes and for overmolding of the free edges of the metal stamping.

Similar content being viewed by others

References

M. Grujicic, V. Sellappan, G. Arakere, N. Seyr, M. Erdmann, Computational Feasibility Analysis of Direct-Adhesion Polymer-To-Metal Hybrid Technology for Load-Bearing Body-In-White Structural Components, Journal of Materials Processing Technology, 195, 282–298, 2008.

O.J. Zoellner and J.A. Evans, Plastic-Metal Hybrid. A New Development in the Injection Molding Technology, ANTEC 2002 Annual Technical Conference, San Francisco, CA, 1-4, 2002

Plastic-Metal Hybrid Material, http://www.hbmedia.net/polymotive/polymotive/2003/01/articles/frontend1.shtml

D. Recktenwald, Advanced Adhesives Foster Hybrid Structures, Machine Design, 77, 21, 124–126, 2005.

M. Grujicic, V. Sellappan, M. A. Omar, N. Seyr, M. Erdmann, An Overview of the Polymer-to-Metal Direct-Adhesion Hybrid Technologies for Load-Bearing Automotive Components, Journal of Materials Processing Technology, 197, 363–373, 2008.

V. Hamel, J. M. Roelandt, J. N. Gacel, F. Schmit, Finite Element Modeling of Clinch Forming with Automatic Remeshing, Computers and Structures, 77, 185–200, 2000.

CATIA, Version V5R16, Dassault Systems, www.3ds.com, 2007

HyperMesh, Version 8.0SR, Altair Engineering Inc., www.altair.com, 2007

ABAQUS, Version 6.6, User Documentation, Dassault Systems, www.3ds.com, 2006

Moldflow Plastics Insight Version 6.1, User Documentation, Moldflow Corporation, Framingham, MA, 2006

MATLAB, The Language of Technical Computing, 7th Edition, The Math Works Inc., MA, 2006.

M. Grujicic, V. Sellappan, B. Pandurangan, G. Li, M. Erdmann, and J. Holzleitner, Computational Analysis of Injection-Molding Residual-Stress Development in Direct-Adhesion Polymer-to-Metal Hybrid Body-in-White Components, J. Mater. Process. Technol., 2008, 203, p 19–36

Acknowledgments

The material presented in this article is based on work conducted as a part of the project “Lightweight Engineering: Hybrid Structures: Application of Metal/Polymer Hybrid Materials in Load-bearing Automotive Structures” supported by BMW AG, München, Germany. The authors are indebted to Drs. David Angstadt, Greg Moco, and Lonny Thomson for stimulating discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grujicic, M., Sellappan, V., Arakere, G. et al. The Potential of a Clinch-Lock Polymer Metal Hybrid Technology for Use in Load-Bearing Automotive Components. J. of Materi Eng and Perform 18, 893–902 (2009). https://doi.org/10.1007/s11665-008-9325-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9325-2