Abstract

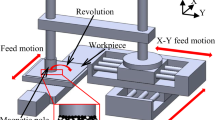

This paper aims to improve the surface integrity and surface homogeneity with various trajectories by a newly self-designed experiment device. In the experiments, three kinds of polishing trajectories were studied with attached revolution motion to magnetic abrasive brush (MAB) based on conventional magnetic abrasive finishing (MAF) process. The surface roughness, the cross-sectional shape, and the 3D micro-morphology were chosen as the response variables to explore the feasibility and benefits of the proposed improving polishing method. The results show that the plane homogeneity and surface quality improved in varying degrees after improving the polishing trajectory. In addition, combining MAF theory to analyze related reasons, the trajectory expression of the magnetic abrasive particles (MAPs) was established and was simulated by Graph software. The theoretical analysis is consistent with the experimental results which indicated that analysis of polishing trajectory can be used to predict polishing results. Thus, it is feasible to plan polishing trajectory reasonable according to workpiece profile and surface quality requirements.

Similar content being viewed by others

References

Tsuchiya K, Shimizu Y, Sakaki K, Satio M (1933) Polishing mechanism of magnetic abrasion. J Jpn I Met 57(11):1333–1338

Jayakumar P, Ray S, Radhakrishnan V (1997) Optimising progress parameters of magnetic abrasive machining to reduce the surface roughness value. J Spacecr Technol 7(1):58–64

Singh L, Khangura SS, Mishra PS (2010) Performance of abrasive used in magnetically assisted finishing: a state of the art review. Int J Adv Manuf Technol 3:215–227

Singh DK, Jain VK, Raghuram V, Komanduri R (2005) Analysis of surface texture generated by a flexible magnetic abrasive brush. Wear 259(7):1254–1261

Kim SO, Kwak JS (2008) Magnetic force improvement and parameter optimization for magnetic abrasive polishing of AZ31 magnesium alloy. Trans Nonferrous Met Soc China 18:s369–s373

Sigh P, Samra PS, Singh L (2011) Internal finishing of cylindrical pipes using sintered magnetic abrasive. Int J Eng Sci 3:5747–5753

Shinmura T, Takazawa K, Hatano E, Matsunaga M, Matsuo T (1990) Study on magnetic abrasive finishing. CIRP Ann-Manuf Techn 39(1):325–328

Jain VK (2009) Advanced machining processes. Allied Publishers, New Delhi

Lambropoulos JC, Miao C, Jacobs SD (2010) Magnetic field effects on shear and normal stresses in magnetorheological finishing. Opt Express 18(19):19713–19723

Wang AC, Lee SJ (2009) Study the characteristics of magnetic finishing with gel abrasive. Int J Mach Tools Manuf 49(14):1063–1069

Jayswal SC, Jain VK, Dixit PM (2005) Modeling and simulation of magnetic abrasive finishing process. Int J Adv Manuf Technol 26:477–490

Kim TW, Kwak JS (2010) A study on deburring of magnesium alloy plate by magnetic abrasive polishing. Int J Precis Eng Man 11(2):189–194

Jain VK, Kumar P, Behera PK, Jayswal SC (2001) Effect of working gap and circumferential speed on the performance of magnetic abrasive finishing process. Wear 250(1):384–390

Mulik RS, Pandey PM (2011) Magnetic abrasive finishing of hardened AISI 52100 steel. Int J Adv Manuf Technol 55:501–515

Yin S, Shinmura T (2004) A comparative study: polishing characteristics and its mechanisms of three vibration modes in vibration-assisted magnetic abrasive polishing. Int J Mach Tools Manuf 44(4):383–390

Kwak JS (2012) Mathematical model determination for improvement of surface roughness in magnetic-assisted abrasive polishing of nonferrous AISI316 material. Trans Nonferrous Met Soc China 22:s845–s850

Givi M, Tehrani AF, Mohammadi A (2012) Polishing of the aluminum sheets with magnetic abrasive finishing method. Int J Adv Manuf Technol 61:989–998

Lin CT, Yang LD, Chow HM (2007) Study of magnetic abrasive finishing in free-form surface operations using the Taguchi method. Int J Adv Manuf Technol 34:122–130

Shen XA (2009) Abrasive particles trajectory simulation of plane polishing. Machinery 5:16–18

Kumar G, Yadav V (2009) Temperature distribution in the workpiece due to plane magnetic abrasive finishing using FEM. Int J Adv Manuf Technol 41(11–12):1051–1058

Zou YH, Jiao AY, Aizawa T (2010) Study on plane magnetic abrasive finishing process-experimental and theoretical analysis on polishing trajectory. Adv Mater Res 126:1023–1028

Grzeshika W, Rechb J, Wanat T (2007) Surface finish on hardened bearing steel parts produced by superhard and abrasive tools. Int J Mach Tools Manuf 47(2):255–262

Mirian SS, Fadaei A, Safavi SM, Farzin M, Salimi M (2011) Improving the quality of surface in the polishing process with the magnetic abrasive powder polishing using a high-frequency induction heating source on CNC table. Int J Adv Manuf Technol 55(5–8):601–610

Smaoui M, Bouaziz Z, Zghal A, Dessein G, Baili M (2011) Simulation of the deflected cutting tool trajectory in complex surface milling. Int J Adv Manuf Technol 56:463–474

Yamaguchi H, Shinmura T (1999) Study of the surface modification resulting from an internal magnetic abrasive finishing process. Wear 225:246–255

Wang D, Shinmura T, Yamaguchi H (2004) Study of magnetic field assisted mechanochemical polishing process for inner surface of Si < sub > 3</sub > N < sub > 4</sub > ceramic components: finishing characteristics under wet finishing using distilled water. Int J Mach Tools Manuf 44(14):1547–1553

Yamaguchi H, Kang J, Hashimoto F (2011) Metastable austenitic stainless steel tool for magnetic abrasive finishing. CIRP Ann-Manuf Techn 60(1):339–342

Liu ZQ, Chen Y, Li YJ, Zhang X (2013) Comprehensive performance evaluation of the magnetic abrasive particles. Int J Adv Manuf Technol 68(1–4):631–640

Pan J, Yan Q, Xu X, Zhu J, Wu Z, Bai Z (2012) Abrasive particles trajectory analysis and simulation of cluster magnetorheological effect plane polishing. Phys Procedia 25:176–184

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiao, A.Y., Quan, H.J., Li, Z.Z. et al. Study on improving the trajectory to elevate the surface quality of plane magnetic abrasive finishing. Int J Adv Manuf Technol 80, 1613–1623 (2015). https://doi.org/10.1007/s00170-015-7136-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7136-9