Abstract

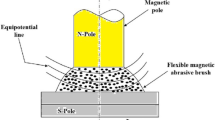

A mathematical model is developed for the prediction of magnetic potential using Maxwell’s equations and finite element method is used to find the magnetic potential distribution within the gap between tool bottom surface and workpiece top surface. From magnetic potential model, the magnetic pressure developed and corresponding heat flux generated on workpiece surface are evaluated. Further a mathematical model is developed for heat transfer in the workpiece and again finite element method is used for the prediction of temperature rise in the workpiece. The effects of various operating input parameter on magnetic potential distribution in the gap and temperature rise in the workpiece has been studied.

Similar content being viewed by others

References

Shinmura T, Takazava K, Hitano E, Aizawa T (1987) Study on magnetic abrasive process-Effect of various types of magnetic abrasives on finishing characteristics. Journal of the Japan Society of Precision Engineering 21(2):139–141

Shinamura T, Wang FH (1994) A new process for precision finishing of silicon nitride fine ceramics by the application of magnetic abrasive machining using chromium-oxide abrasives mixed with iron particles. Journal of the Japan Society of Precision Engineering 28(3):229–230

Kim JD, Choi MS (1995) Simulation for the prediction of surface-accuracy in magnetic abrasive machining. J Mater Process Tech 53:630–642 DOI 10.1016/0924–0136(94)01753-N

Hou Z, Komanduri R (1998) Magnetic field assisted finishing of ceramics-part II: On the thermal aspects of magnetic float polishing (MFP) of ceramics balls. Journal of Tribology Transactions of ASME 120:652–659 DOI 10.1115/1.2833762

Reddy JN (2003) An introduction to finite element method, 2nd edn. Tata McGraw-Hill, New Delhi

Griffith DJ (2000) Introduction to electromagnetism, 3rd edn. Prentice Hall of India Pvt. Ltd, New Delhi

Shaw MC (1996) Principles of abrasive processing. Clarenden, Oxford

Seth SP (2001) A course in electrical engineering materials (Physics, Properties and Application), 2nd edn. Dhanapat Rai and Sons, New Delhi

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, G., Yadav, V. Temperature distribution in the workpiece due to plane magnetic abrasive finishing using FEM. Int J Adv Manuf Technol 41, 1051–1058 (2009). https://doi.org/10.1007/s00170-008-1557-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1557-7