Abstract

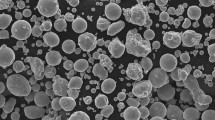

Due to environment-friendly nature, water-soluble binder systems have received much attention in recent years. Polyethylene glycol (PEG) and polymethyl methacrylate (PMMA) binder system is one such example and has been widely reported in the literature. In this paper, a comprehensive investigation of PEG/PMMA binder system has been carried out. Feedstocks were made using stainless steel 17-4PH powder, and subsequently, conventional and micrometal injection moulding (μMIM) processes were carried out. Differential scanning calorimetry (DSC) and fracture surface analysis of moulded samples were performed for complete evaluation. It was found that despite great potential, there are certain drawbacks associated with this binder system. The main problem is the formation of shrinkage voids during solidification. It is proposed that this binder system is more suitable for μMIM process that has an inherently higher cooling rate.

Similar content being viewed by others

References

Weil SK, Nyberg E, Simmons K (2006) A new binder for powder injection molding titanium and other reactive metals. J Mater Process Technol 176(1-3):205–209. doi:10.1016/j.jmatprotec.2006.03.154

Angermann HH, Biest OVD (1995) Scientific and technological progress in binder burnout from metal injection molded compacts. Mater Manuf Process 10(3):439–451. doi:10.1080/10426919508935037

Wen G, Cao P, Gabbitas B, Zhang D, Edmonds N (2012) Development and design of binder systems for titanium metal Injection molding: an overview. Metall Mater Trans A 44(3):1530–1547. doi:10.1007/s11661-012-1485-x

Rivers RD (1978) Method of injection molding powder metal parts. USA Patent 4113480

Cao MY, O’Connor JW (1992) Chung CI A new water-soluble solid polymer solution binder for powder injection moulding. In: Powder Metallurgy World Congress. Princeton, San Francisco, APMI

Chuankrerkkul N, Sooksaen P, Pakunthod P, Kosalwit T, Pinthong W (2013) Powder injection moulding of alumina using PEG/PVB binder systems. Key Eng Mater 545:173–176

Hayat MD, Wen G, Zulkifli MF, Cao P (2015) Effect of PEG molecular weight on rheological properties of Ti-MIM feedstocks and water debinding behaviour. Powder Technol 270(0):296–301. doi:10.1016/j.powtec.2014.10.035, Part A

Herranz G (2012) Control of carbon content in metal injection molding (MIM). In: Heaney DF (ed) Handbook of metal injection molding. Woodhead Publishing, USA, pp 265–304

Sidambe AT, Figueroa IA, Hamilton HGC, Todd I (2012) Metal injection moulding of CP-Ti components for biomedical applications. J Mater Process Technol 212(7):1591–1597. doi:10.1016/j.jmatprotec.2012.03.001

Liu W, Xie Z, Zhang X, Jia C, Cheng L, Liu G, Xue W (2014) Optimisation of compositions of PEG/PMMA binder system in ceramic injection moulding via water debinding. Adv Appl Ceram 0 (0):1743676114Y.0000000190. doi:10.1179/1743676114Y.0000000190

Chuankrerkkul N, Messer PF, Davies HA (2008) Application of polyethylene glycol and polymethyl methacrylate as a binder for powder injection moulding of hardmetals. Chiang Mai J Sci 35(1):188–195

Chen G, Wen G, Edmonds N, Cao P, Li YM (2012) Debinding kinetics of a water soluble binder system for titanium alloys metal injection moulding. Key Eng Mater 520:174–180. doi:10.4028/www.scientific.net/KEM.520.174

Omar MA, Davies HA, Messer PF, Ellis B (2001) The influence of PMMA content on the properties of 316L stainless steel MIM compact. J Mater Process Technol 113(1–3):477–481. doi:10.1016/S0924-0136(01)00641-0

Sulong AB, Muhamad N, Arifin A, Yong KB (2012) Optimizing injection parameter of metal injection molding processes using the feedstock of 16 μm stainless steel powder (SS316L), PEG, PMMA and stearic acid. J Appl Sci Res 8(6):2998–3003

Anwar MY, Messer PF, Ellis B, Davies HA (1995) Injection moulding of 316L stainless steel powder using novel binder system. Powder Metall 38(2):113–119

Ibrahim MHI, Muhamad N, Sulong AB, Murtadhahadi, Jamaluin KR, Ahmat S, Nor NHM (2008) Water atomised stainless steel powder for micro metal injection molding: optimization of rheological properties In: Malaysian Metallurgical Conference, UKM, Bangi, Malaysia, Asian Network for Scientific Information

Mark HF (1986) 1,2-Expoxide polymers: ethylene oxide polymers and copolymers. Encyclopedia of polymer science and engineering. Wiley

McCrum NG, Buckley CP, Bucknall CB (1997) Principles of polymer engineering. 2nd edition. Oxford University Press

Shin HS, Jung YM, Oh TY, Chang T, Kim SB, Lee DH, Noda I (2002) Glass transition temperature and conformational changes of poly(methyl methacrylate) thin films determined by a two-dimensional map representation of temperature-dependent reflection–absorption FTIR spectra. Langmuir 18(15):5953–5958. doi:10.1021/la020258y

Groeninckx G, Vanneste M, Everaert V (2003) Crystallization, morphological structure, and melting of polymer blends. In: Utracki LA (ed) Polymer blends handbook, Springer Netherlands, pp 203-294. doi:10.1007/0-306-48244-4_3

Al-Hussam AM, Aqeel SM, Al-Gunaid MQ (2011) Characterization and solution properties of poly(methyl metha-acrylate)–poly(ethylene glycol) lends. Thamar Univ J Nat Appl Sci A 4:67–75

Zhang W, Zhang XM (2014) Study on surface structure and properties of PMMA/PEG copolymer coatings. Mater Res Innov 18(S2):S2-1028–S1022-1033. doi:10.1179/1432891714Z.000000000474

Sarı A, Alkan C, Karaipekli A, Uzun O (2010) Poly(ethylene glycol)/poly(methyl methacrylate) blends as novel form-stable phase-change materials for thermal energy storage. J Appl Polym Sci 116(2):929–933. doi:10.1002/app.31623

He L-h, Xue R, Yang D-b, Liu Y, Song R (2009) Effects of blending chitosan with PEG on surface morphology, crystallization and thermal properties. Chin J Polym Sci 27(04):501–510. doi:10.1142/S0256767909004175

K-i I, Yoshioka S, Kojima S, Randolph T, Carpenter J (1996) Effects of sugars and polymers on crystallization of poly(ethylene glycol) in frozen solutions: phase separation between incompatible polymers. Pharm Res 13(9):1393–1400. doi:10.1023/A:1016086319851

Fort J, Krill S, Law D, Qiu Y, Schmitt E (2007) Inhibitors of crystallization in a solid dispersion. USA Patent US20070249692

Thomas S, Grohens Y, Jyotishkumar P (2015) Characterization of polymer blends: miscibility, morphology and interfaces. Wiley-VCH Verlag GmbH, Weinheim

da Silva EP, Tavares MIB (1998) Solid state NMR study of poly(methyl methacrylate)/polyvinylpyrrolidone blends. Polym Bull 41(3):307–310. doi:10.1007/s002890050367

Cheng J, Wang S, Chen S, Zhang J, Wang X (2012) Crystallization behavior and hydrophilicity of poly(vinylidene fluoride)/poly(methyl methacrylate)/poly(vinyl pyrrolidone) ternary blends. Polym Int 61(3):477–484. doi:10.1002/pi.3185

Li Y, Ma Q, Huang C, Liu G (2013) Crystallization of poly (ethylene glycol) in poly (methyl methacrylate) networks. Mater Sci 19 (2). doi:10.5755/j01.ms.19.2.4430

Pielichowski K, Flejtuch K (2002) Differential scanning calorimetry studies on poly(ethylene glycol) with different molecular weights for thermal energy storage materials. Polym Adv Technol 13(10-12):690–696. doi:10.1002/pat.276

Ren J (2010) Modification of PLA. In: Biodegradable poly(lactic acid): synthesis, modification, processing and applications. Springer Berlin Heidelberg, pp 38-141. doi:10.1007/978-3-642-17596-1_4

Bogdanov B, Vidts A, Schacht E, Berghmans H (1999) Isothermal crystallization of poly(ε-caprolactone–ethylene glycol) block copolymers. Macromolecules 32(3):726–731. doi:10.1021/ma980226a

Wable G, Chada S, Neal B, Fournelle R (2005) Solidification shrinkage defects in electronic solders. JOM 57(6):38–42. doi:10.1007/s11837-005-0134-x

Swillo SJ, Perzyk M (2011) Automatic inspection of surface defects in die castings after machining. Arch Found Eng 11(3):231–236

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hayat, M.D., Li, T., Wen, G. et al. Suitability of PEG/PMMA-based metal injection moulding feedstock: an experimental study. Int J Adv Manuf Technol 80, 1665–1671 (2015). https://doi.org/10.1007/s00170-015-7133-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7133-z