Abstract

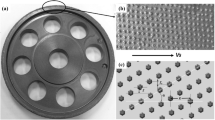

The monolayer brazed wheels, which have several advantages such as high bonding strength, high chip storage space, and uniform grit spacing, have drawn much attention in the grinding of different-to-machine materials. As pursuing for higher machining efficiency, special attention has been devoted to high-speed grinding. However, when the grinding wheel is fabricated by conventional brazing technology, the thermal deformation of the wheel is remarkable, and the accuracy of brazed wheel cannot meet the needs of high-speed grinding. To take the challenge of the unexpected wheel deformation after brazing, a new brazing technology, named continuous induction brazing, was proposed to fabricate monolayer brazed cubic boron nitride (CBN) wheel with diameter d s = 400 mm for high-speed grinding. The experiments and analysis revealed that chemical bonding between CBN grains and filler alloy was achieved. The maximum thermal deformation of the newly brazed wheel was less than 16 μm. High-speed grinding performance of the brazed CBN wheel for grinding of Inconel718 superalloy showed that the grinding wheel has good bonding strength. Moreover, a relatively satisfactory ground surface quality was achieved.

Similar content being viewed by others

References

Qu NS, Xu ZY (2013) Improving machining accuracy of electrochemical machining blade by optimization of cathode feeding directions. Int J Adv Manuf Technol 68(5-8):1565–1572

Webster J, Tricard M (2004) Innovations in abrasive products for precision grinding. CIRP Ann Manuf Technol 53(2):597–617

Soo SL, Hood R, Lannette M, Aspinwall DK, Voice WE (2011) Creep feed grinding of burn-resistant titanium (BuRTi) using superabrasive wheels. Int J Adv Manuf Technol 53(9-12):1019–1026

Chattopadhyay AK, Hintermann HE (1993) On brazing of cubic boron nitride abrasive crystals to steel substrate with alloys containing Cr or Ti. J Mater Sci 28(21):5887–5893

Bhaduri D, Kumar R, Chattopadhyay AK (2011) On the grindability of low-carbon steel under dry, cryogenic and neat oil environments with monolayer brazed cBN and alumina wheels. Int J Adv Manuf Technol 57(9-12):927–943

Pal B, Chattopadhyay AK, Chattopadhyay AB (2010) Development and performance evaluation of monolayer brazed cBN grinding wheel on bearing steel. Int J Adv Manuf Technol 48(9-12):935–944

Zhan YJ, Xu XP (2012) An experimental investigation of temperatures and energy partition in grinding of cemented carbide with a brazed diamond wheel. Int J Adv Manuf Technol 61(1-4):117–125

Ding WF, Xu JH, Chen ZZ, Su HH, Fu YC (2010) Grindability and surface integrity of cast nickel-based superalloy in creep feed grinding with brazed CBN abrasive wheels. Chin J Aeronaut 23(04):501–510

Chattopadhyay AK, Chollet L, Hintermann HE (1991) Induction brazing of diamond with Ni-Cr hardfacing alloy under argon atmosphere. Surf Coat Technol 45(1-3):293–298

Li QL, Xu JH, Su HH (2013) Simulation of temperature field in ultra-high frequency induction heating and verification. Trans Nanjing Univ Aeronaut Astronaut 30(2):155–161

Valery R, Don L, Raymond C, Micah B (2003) Handbook of induction heating. Marcel Dekker Inc, New York

Su HH, Li QL, Xu JH, Fu YC (2012) Study on influence factors of temperature in localized ultra-high frequency induction brazing. Trans Chin Weld Inst 33(12):13–17

Johari MR, Hadian AM (2014) Effect of brazing time on microstructure and mechanical properties of cubic boron nitride/steel joints. Ceram Int 40(6):8519–8524

Ding WF, Xu JH, Shen M, Fu YC, Xiao B (2006) Thermodynamic and kinetic analysis of interfacial reaction between CBN and titanium activated Ag-Cu alloy. Mater Sci Technol 22(1):105–109

Xu P (2011) High speed grinding of nickel superalloy using CBN wheels. Master dissertation, Nanjing, China

Malkin S (1989) Grinding technology: theory and application of machining with abrasives. John Wiley & Sons, New York

Ding WF, Xu JH, Chen ZZ, Su HH, Fu YC (2010) Wear behavior and mechanism of single-layer brazed CBN abrasive wheels during creep-feed grinding cast nickel-based superalloy. Int J Adv Manuf Technol 51(5-8):541–550

Yao CF, Jin QC, Huang XC, Wu DX, Ren JX, Zhang DH (2013) Research on surface integrity of grinding Inconel 718. Int J Adv Manuf Technol 65(5-8):1019–1030

Chen ZZ, Xu JH, Ding WF, Ma CY, Fu YC (2015) Grinding temperature during high-efficiency grinding Inconel 718 using porous CBN wheel with multilayer defined grain distribution. Int J Adv Manuf Technol 77(1-4):165–172

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Q., Xu, J., Su, H. et al. Fabrication and performance of monolayer brazed CBN wheel for high-speed grinding of superalloy. Int J Adv Manuf Technol 80, 1173–1180 (2015). https://doi.org/10.1007/s00170-015-7125-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7125-z