Abstract

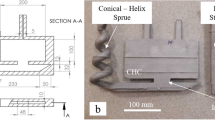

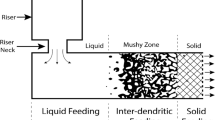

Photopolymer-based stereo-lithography (SL) rapid prototyping patterns with honeycomb internal structure reduce lead time and material cost for pattern manufacturing and also minimize ceramic mold residue after pattern removal in investment casting process. However, relatively larger thermal expansion of SL pattern tends to cause ceramic shell cracking during the pattern thermal removal. The anisotropy of SL pattern properties incurs different stress states of ceramic shell depending on the orientation of the honeycomb structure. In this work, a comprehensive thermo-mechanical coupled finite element model was developed to characterize the anisotropy of SL pattern and its effect on stress in investment casting shell molds. An experimental-based thermal degradation material model was developed considering anisotropy of the thermo-mechanical properties of SL pattern. The static analysis of slurry dipping and transient thermo-mechanical analysis of the pattern thermal removal process were performed. Both the pattern and ceramic shell behavior were studied and validated with experimental findings. Facesheet thickness/facesheet-to-core ratio and orientation of honeycomb structure were found to be the key factors to shell stress during pattern firing. Decreased facesheet thickness reduces stress in shell but also increases shell stress sensitivity to anisotropy of SL pattern. The developed tool provides an effective and efficient way to evaluate and optimize the structure of SL pattern for investment casting process.

Similar content being viewed by others

References

Jones S, Yuan C (2003) Advances in shell moulding for investment casting. Journal of Materials Processing Technology 135(2–3):258–265

Foster G (1994) “Flashfire Dewax for Today’s Investment Casting Foundry”, Investment Casting Institute 42nd Annual Meeting, pp. 1–11, Atlanta, Georgia, USA, September

Kline D, Lekakh S, Mahimkar C, Richards V (2009) Crack formation in ceramic shell during foam pattern firing. Technical and Operating Conference, Chicago

Everhart W, Lekakh S, Richards V, Smith J, Li H, Chandrashekhara K, Zhao H, Nam P (2012) “Foam pattern aging and its effect on crack formation in investment casting ceramic shells,” Proceedings of American Foundry Society (AFS) Conference, pp. 1–8, Schaumburg, IL, April 5–8

Bird C, Mertz J (1987) “Method of investment casting employing microwave susceptible material,” US4655276

Cheah C, Chua C, Lee C, Feng C, Totong K (2004) Rapid prototyping and tooling techniques: a review of applications for rapid investment casting. The International Journal of Advanced Manufacturing Technology 25(3–4):308–320

Hague R, Dickens PM (2001) “Improvements in investment casting with stereolithography patterns”, Proceedings of the Institution of Mechanical Engineers. Part B: Journal of Engineering Manufacture 215(1):1–11

Hague R, D’Costa G, Dickens PM (2001) Structural design and resin drainage characteristics of QuickCast 2.0. Rapid Prototyping Journal 7(2):66–73

Yao W, Leu M (2000) Analysis and design of internal web structure of laser stereolithography patterns for investment casting. Materials and Design 21(2):101–109

Ferreira JC, Mateus AS (2002) Simulation and analysis of fracture in stereolithography QuickCast™ patterns and in ceramic shells for investment casting. Key Engineering Materials 230:259–262

Norouzi Y, Rahmati S, Hojjat Y (2009) A novel lattice structure for SL investment casting patterns. Rapid Prototyping Journal 15(4):255–263

Zhu JH, Zhang WH, Gu XJ (2010) On the topology optimization design for the stereolithography based investment casting model. Advanced Materials Research 139:1464–1467

Zhao H, Xu M, Li H, Everhart W, Lekakh S, Richards V, Chandrashekhara K, Nam P (2011) “Characterization of low density polymer patterns for large steel investment casting,” Investment Casting Institute 58th Technical Conference & Equipment Expo 2011, pp. 1–13, Covington, KY, Oct. 9–12

ABAQUS Version 6.10 (2010) Manual, Dassault Systèmes

ASTM C1161-02c (2008) “Standard test method for flexural strength of advanced ceramics at ambient temperature,” e1

ASTM C 20-00 (2000) Standard test methods for apparent porosity, water absorption, apparent specific gravity and bulk density of burned refractory brick and shapes by boiling water

Xu M, Lekakh S, Mahimkar C, Richards V (2012) “Measurements and confirmation of thermal properties of investment ceramic shell by multiple methods,” American Foundry Society Metal Congress

Komaragiri S, Li H, Lekakh S, Chandrashekhara K, Richards V (2013) “Effects of complex geometry, shell thickness and firing regimes on shell cracking in industrial investment casting shells during rigid polymer pattern removal,” Proceedings of CastExpo and the Metalcasting Congress, St. Louis, MO, April 6–9

Li H, Chandrashekhara K, Komaragiri S, Lekakh SN, Richards VL (2014) Crack prediction using nonlinear finite element analysis during pattern removal in investment casting process. Journal of Materials Processing Technology 214(7):1418–1426

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Chen, J., Chandrashekhara, K. et al. Characterization and modeling of anisotropic SL pattern during investment casting process. Int J Adv Manuf Technol 80, 1933–1943 (2015). https://doi.org/10.1007/s00170-015-7090-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7090-6