Abstract

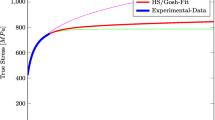

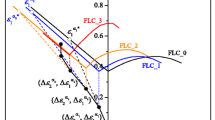

Forming limit curve (FLC) has been applied for evaluating the formability of sheet metal in a standardized way. Various experimental procedures and theoretical models were introduced in the past decades. However, bunches of tests required in the experimental determination of FLC make the procedures more burdensome. In the present study, a combination of experiment and simulation study was conducted with AA5182-O in terms of localized necking and fracture. In the proposed methodology, three experimental procedures, uniaxial tensile, deep drawing with round cup, and dome stretching, were performed and analyzed by using the finite element (FE) simulations. The feasibility of FE models were preliminarily examined by the experimental results. The progression-dependent criterion was developed to determine the process of localized necking to fracture. In the criterion, evolutions of principal strains and their derivatives were calculated and calibrated by validated FE models. The limiting strains obtained from the proposed method showed a good agreement with FLCs obtained using other methods.

Similar content being viewed by others

References

Keeler SP (1965) Determination of forming limits in automotive stampings. Sheet Metal Ind 42:683–691. doi:10.4271/650535

Goodwin GM (1968) Application of strain analysis to sheet metal forming problems in the press shop. Metal Ital 60:764–774. doi:10.4271/680093

Marciniak Z, Kuczynski K (1967) Limit strains in the processes of stretch forming sheet metal. Int J Mech Sci 9:609–620. doi:10.1016/0020-7403(67)90066-5

Nakazima K, Kikuma T, Hasuka K (1971) Study on the formability of steel sheets. Yawata Tech Rep No 284:678–680

Gerlach J, Keßler L, Köhler A, Paul U (2010) Method for the approximate calculation of forming limit curves using tensile test results. Stahl Eisen 130:55–61

Abspoel M, Scholting ME, Droog JMM (2013) A new method for predicting forming limit curves from mechanical properties. J Mater Process Technol 213(5):759–769. doi:10.1016/j.jmatprotec.2012.11.022

Tigrinho LMV, Chemin Filho RA, Marcondes PVP (2013) Fracture analysis approach of DP600 steel when subjected to different stress/strain states during deformation. Int J Adv Manuf Technol 69(5–8):1017–1024. doi:10.1007/s00170-013-5104-9

Story JM (1982) Variables affecting dome test results. J Applied Metal working 2(2):119–125. doi:10.1007/BF02834209

Groseclose A, Son HS, Dykeman J, Altan T (2014), Determination of biaxial flow stress using the frictionless dome test. 11th International Conference on Technology of Plasticity, Nagoya Congress Center, Nagoya, Japan. ICTP, October

Banabic D, Lazarescu L (2013) Development of a new procedure for the experimental determination of the forming limit curves. CIRP Annals-Manuf Technol 62(1):255–258. doi:10.1016/j.cirp.2013.03.051

Dilmec M, Halkaci HS, Ozturk F, Livatyali H (2013) Effects of sheet thickness and anisotropy on forming limit curves of AA2024-T4. Int J Adv Manuf Technol 67(9–12):2689–2700. doi:10.1007/s00170-012-4684-0

Park DH, Yarlagadda PK (2008) Effects of punch load for elliptical deep drawing product of automotive parts. Int J Adv Manuf Technol 35(7–8):814–820. doi:10.1007/s00170-006-0758-1

Li B, Nye TJ, Wu PD (2010) Predicting the forming limit diagram of AA 5182-O. J Strain Anal Eng Des 45(4):255–273. doi:10.1243/03093247JSA608

Takuda H, Mori K, Hatta N (1999) The application of some criteria for ductile fracture to the prediction of the forming limit of sheet metals. J Mater Process Technol 95(1):116–121. doi:10.1016/S0924-0136(99)00275-7

Takuda H, Mori K, Takakura N, Yamaguchi K (2000) Finite element analysis of limit strains in biaxial stretching of sheet metals allowing for ductile fracture. Int J Mech Sci 42(4):785–798. doi:10.1016/S0020-7403(99)00018-1

Aretz H, Keller S, Engler O, Brinkman HJ (2013) A simple ductile failure model with application to AA5182 aluminum sheet forming. Int J Mater Form 4:1–16. doi:10.1007/s12289-013-1127-x

Aretz H, Keller S, Vogt R, Engler O (2011) Modeling of ductile failure in aluminum sheet forming simulation. Int J Mater Form 4(2):163–182. doi:10.1007/s12289-010-1021-8

Swift HW (1952) Plastic instability under plane stress. J Mech Phys Solids 1(1):1–18. doi:10.1016/0022-5096(52)90002-1

Sing WM, Rao KP (2000) On the prediction of the effects of process parameters upon forming limit strains in sheet metals. Int J Mech Sci 42:451–472. doi:10.1016/S0020-7403(99)00009-0

Tseng HC, Hung C, Huang CC (2010) An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment. Int J Adv Manuf Technol 49(9–12):1029–1036. doi:10.1007/s00170-009-2446-4

International Standard ISO 12004-2:2008 (2008) Metallic materials-sheet and strip- determination of forming limit curves, Part 2: Determination of forming limit curves in the laboratory. International Organization for Standardization, Geneva, Switzerland

Situ Q, Jain M, Bruhis M (2006) A suitable criterion for precise determination of incipient necking in sheet materials. Mater Sci Forum Vol 519:111–116. doi:10.4028/www.scientific.net/msf. 519-521.111

Situ Q, Jain MK, Metzger DR (2011) Determination of forming limit diagrams of sheet materials with a hybrid experimental–numerical approach. Int J Mech Sci 53(9):707–719. doi:10.1016/j.ijmecsci.2011.06.003

Merklein M, Kuppert A, Geiger M (2010) Time dependent determination of forming limit diagrams. CIRP Annals-Manuf Technol 59(1):295–298. doi:10.1016/j.cirp.2010.03.001

Martínez AJ, Vallellano C, Morales D (2009) On the experimental detection of necking in stretch-bending tests. AIP Conf Proc 1181:500. doi:10.1063/1.3273668

Martínez AJ, García FJ, Vallellano C (2014) New approaches to detect the onset of localized necking in sheets under through-thickness strain gradients. Mater Des 57:135–145. doi:10.1016/j.matdes.2014.01.012

Kim H, Altan T, Yan QG (2009) Evaluation of stamping lubricants in forming advanced high strength steels (AHSS) using deep drawing and ironing tests. J Mater Process Technol 209(8):4122–4133. doi:10.1016/j.jmatprotec.2008.10.007

Grote KH, Antonsson EK (2009) Springer Handbook of Mechanical Engineering, Springer

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Sot Lond A193:281–297. doi:10.1098/rspa.1948.0045

Barlat F, Maeda Y, Chung K (1997) Yield function development for aluminum alloy sheets. J Mech Phys Solids 45(11):1727–1763. doi:10.1016/S0022-5096(97)00034-3

Barlat F, Brem JC, Yoon JW, Chung K (2003) Plane stress yield function for aluminum alloy sheets—part 1: theory. Int J Plast 19(9):1297–1319. doi:10.1016/S0749-6419(02)00019-0

Brem JC, Barlat F, Dick RE, Yoon JW (2005) Characterizations of aluminum alloy sheet materials Numisheet 2005. Numisheet Part B 25:1179–1190. doi:10.1063/1.2011346

Banabic D, Siegert K (2004) Anisotropy and formability of AA5182-0 aluminum alloy sheets. CIRP Annals-Manuf Technol 53(1):219–222. doi:10.1016/S0007-8506(07)60683-0

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ju, L., Mao, T. & Li, H. An experimental and numerical study of forming limits of AA5182-O. Int J Adv Manuf Technol 79, 221–228 (2015). https://doi.org/10.1007/s00170-015-6819-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6819-6