Abstract

Enhancing the performance of cutting tools is an important factor in reducing production costs. Cutting tools are subjected to processes such as heat treatment and coating in order to improve their performance. Cryogenic treatment, which is also known as sub-zero heat treatment, has made significant contributions to the improvement of wear resistance, tool life, dimensional integrity, and product quality of cutting tools. The mode of application of cryogenic treatment and the type of cutting tool both affect tool performance. Therefore, it is necessary to examine the way cryogenic treatment is applied to cutting tools and its effects on their performance. This study reviews the literature on the performance of cryo-treated cutting tools.

Similar content being viewed by others

References

Gu K, Wang J, Zhou Y (2014) Effect of cryogenic treatment on wear resistance of Ti-6Al-4V alloy for biomedical applications. J Mech Behav Biomed 30:131–139

Baldissera P, Delprete C (2008) Deep cryogenic treatment: a bibliographic review. O Mech Eng J 2:1–11

Amini K, Amin A, Sirus J (2012) Investigating the effect of holding duration on the microstructure of 1.2080 tool steel during the deep cryogenic heat treatment. Vacuum 86:1534–1540

Susheel K (2010) Cryogenic processing: a study of materials at low temperatures. J Low Temp Phys 158:934–945

Yıldız Y, Nalbant M (2008) A review of cryogenic cooling in machining processes. Int J Mach Tools Manuf 48:947–964

Sharma VS, Dogra M, Suri NM (2008) Advances in the turning process for productivity improvement—a review. J Eng Manuf 222:1417

Balout B, Songmene V, Masounave J (2007) An experimental study of dust generation during dry drilling of pre-cooled and pre-heated workpiece materials. J Manuf Process 9(1):23–34

Ranajit G, Zurecki Z, Frey JH (2003) Cryogenic machining with brittle tools and effect on tool life, proceedings of IMECE’03 16–21

Sharma VS, Dogra M, Suri NM (2008) Cooling techniques for improved productivity in turning. Int J Mach Tools Manuf 49:435–453

Dhar NR, Kamruzzaman M (2007) Cutting temperature, tool wear, surface roughness and dimensional deviation in turning AISI-4037 steel under cryogenic condition. Int J Mach Tools Manuf 47:754–759

Dhar NR, Islam S (2006) Effect of cryogenic cooling by liquid nitrogen jet on tool wear and product quality in turning AISI-9310 steel. ARPN J Eng Appl Sci 1:1–6

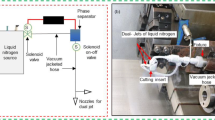

Ahmed MI, Ismail AF, Abakr YA, Amin AKMN (2007) Effectiveness of cryogenic machining with modified tool holder. J Mater Process Technol 185:91–96

Gisip J, Gazo R, Stewart HA (2009) Effects of cryogenic treatment and refrigerated air on tool wear when machining medium density fiberboard. J Mater Process Technol 209:5117–5122

Gandarias A, Lacalle LNL, Azpitarte X, Lamikiz A (2008) Study of the performance of the turning and drilling of austenitic stainless steels using two coolant techniques. Int J Mach Mach Mater 3:1–17

Barron RF (1982) Cryogenic treatment of metals to improve wear resistance. Cryogenics 22:409–413

Yildiz Y, Sundaram MM (2012) Cryogenic machining of composites. Mach Technol Com Mat 365–393

Dhokey NB, Hake A, Kadu S, Bhoskar I, Dey GK (2014) Influence of cryoprocessing on mechanism of carbide development in cobalt-bearing high-speed steel (M35). Metall Mater Trans 45:1508–1516

El-Tayeb NSM, Yap TC, Brevern PV (2010) Wear characteristics of titanium alloy Ti54f or cryogenic sliding applications. Tribol Int 43:2345–2354

Das D, Dutta AK, Toppo V, Ray KK (2007) Effect of deep cryogenic treatment on the carbide precipitation and tribological behavior of D2 steel. Mater Manuf Process 22:474–480

Gogte CL, Likhite A, Peshwe D, Bhokarikar A, Shetty R (2014) Effect of cryogenic processing on surface roughness of age hardenable AA6061 alloy. Mater Manuf Process 29(6):710–714

Li YS, Tao NR, Lu K (2008) Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater 56:230–241

Nayan N, Murty SVSN, Abhay K, Bhanu Pant JHA, Sharma SC, George KM, Sastry GVS (2014) Mechanical properties of aluminium–copper–lithium alloy AA2195 at cryogenic temperatures. Mater Des 58:445–450

Isaak CJ, Reitz W (2008) The effects of cryogenic treatment on the thermal conductivity of GRCop-84. Mater Manuf Process 23:82–91

Jiang Y, Chen D, Chen Z, Liu J (2010) Effect of cryogenic treatment on the microstructure and mechanical properties of AZ31 magnesium alloy. Mater Manuf Process 25:837–841

Firouzdor V, Nejati E, Khomamizadeh F (2008) Effect of deep cryogenic treatment on wear resistance and tool life of M2 HSS drill. J Mater Process Technol 206:467–472

Senthilkumar D, Rajendran I (2011) Influence of shallow and deep cryogenic treatment on tribological behavior of En 19 steel. J Iron Steel Res Int 18(9):53–59

Podgornik B, Leskovšek V, Vižintin J (2009) Influence of deep-cryogenic treatment on tribological properties of P/M high-speed steel. Mater Manuf Process 24:734–738

Thakur D, Ramamoorthy B, Vijayaraghavan L (2008) Influence of different post treatments on tungsten carbide–cobalt inserts. Mater Lett 62:4403–4406

Reddy TVS, Sornakumar T, Reddy MV, Venkatram R (2009) Machinability of C45 steel with deep cryogenic treated tungsten carbide cutting tool inserts. Int J Refract Met Hard Mater 27:181–185

Bensely A, Venkatesh S, Lal DM, Nagarajan G, Rajadurai A, Junik K (2008) Effect of cryogenic treatment on distribution of residual stress in case carburized En 353 steel. Mater Sci Eng A479:229–235

Bensely A, Prabhakaran A, Mohan Lal D, Nagarajan G (2006) Enhancing the wear resistance of case carburized steel (En 353) by cryogenic treatment. Cryogenics 45:747–754

Xuan FZ, Huang X, Tu ST (2008) Comparisons of 30Cr2Ni4MoV rotor steel with different treatments on corrosion resistance in high temperature water. Mater Design 29:1533–1539

Baldissera P, Delprete C (2010) Deep cryogenic treatment of AISI 302 stainless steel: part II—fatigue and corrosion. Mater Design 31:4731–4737

Thornton R, Slatter T, Lewis R (2014) Effects of deep cryogenic treatment on the wear development of H13A tungsten carbide inserts when machining AISI 1045 steel. Prod Eng Res Devel 8:355–364

Gill SS (2012) Machining performance of cryogenically treated AISI M2 high speed steel tools. JERS 3(2):45–49

Gill SS, Singh J, Singh R, Singh H (2012) Effect of cryogenic treatment on AISI M2 high speed steel: metallurgical and mechanical characterization. JMEPEG 21:1320–1326

Senthilkumara D, Rajendran I, Pellizzari M, Siiriainen J (2011) Influence of shallow and deep cryogenic treatment on the residual state of stress of 4140 steel. J Mater Process Technol 211:396–401

Das D, Dutta AK, Ray KK (2009) Optimization of the duration of cryogenic processing to maximize wear resistance of AISI D2 steel. Cryogenics 49:176–184

Priyadarshini A (2007) A study of the effect of cryogenic treatment on the performance of high speed steel and carbide inserts. Rourkela 25–64

Sreerama Reddy TV, Sornakumar T, Venkatarama Reddy M (2009) Turning studies of deep cryogenic treated P-40 tungsten carbide cutting tool inserts-technical communication. Mach Sci Technol 13(2):269–281

Indumathi J, Bijwe J, Ghosh AK, Fahim M, Krishnaraj N (1999) Wear of cryo-treated engineering polymers and composites. Wear 1(225–229):343–353

Pande KN, Peshwe DR, Kumar A (2012) Effect of the cryogenic treatment on polyamide and optimization of its parameters for the enhancement of wear performance. T Indian I Metals 65(3):313–319

Zhang Z, Zhang H, Guo F, Wang K, Jiang W (2009) Enhanced wear resistance of hybrid PTFE/Kevlar fabric/phenolic composite by cryogenic treatment. J Mater Sci 44:6199–6205

Gill SS, Singh H (2013) Cryogenic treatment of materials: cutting tools and polymers. Polym Cryog Temp 245–275

Reitz W, Pendray J (2001) Cryoprocessıng of materials: a review of current status. Mater Manuf Process 16:829–840

Gill SS, Singh H (2010) Cryoprocessing of cutting tool materials—a review. Int J Adv Manuf Technol 48:175–192

Kalsi NS, Sehgal R, Sharma VS (2010) Cryogenic treatment of tool materials: a review. Mater Manuf Process 25:1077–1100

Gill SS, Singh J, Singh R, Singh H (2011) Metallurgical principles of cryogenically treated tool steels—a review on the current state of science. Int J Adv Manuf Technol 54:59–82

Singh LP, Singh J (2011) Effects of cryogenic treatment on high-speed steel tools. J Eng Technol 2:88–93

Jeleńkowski J, Ciski A, Babul T (2010) Effect of deep cryogenic treatment on substructure of HS6-5-2 high speed steel. J Ach Mater Manuf Eng 43:80–86

Kalsi NS, Sehgal R, Sharma VS (2014) Effect of tempering after cryogenic treatment of tungsten carbide–cobalt bounded inserts. Bull Mater Sci 37(2):327–335

Çiçek A, Kıvak T, Uygur İ, Ekici E, Turgut Y (2012) Performance of cryogenically treated M35 HSS drills in drilling of austenitic stainless steels. Int J Adv Manuf Technol 60:65–73

Candane D, Alagumurthi N, Palaniradja K (2013) Effect of cryogenic treatment on microstructure and wear characteristics of AISI M35 HSS. Int J Mater Sci App 2(2):56–65

Bensely A, Venkateswaran S, Subisak AD, Mohan Lal D, Rajadurai A, Lenkey GB, Paulin P (2012) Influence of deep cryogenic treatment on alloy carbide precipitations and mechanical properties of AISI M2 high speed tool steel. Cold Facts 28(2)

Lal DM, Renganarayanan S, Kalanidhi A (2001) Cryogenic treatment to augment wear resistance of tool and die steels. Cryogenics 41:149–155

Gogte CL, Iyer KM, Paretkar RK, Peshwe DR (2009) Deep subzero processing of metals and alloys: evolution of microstructure of AISI T42 tool steel. Mater Manuf Process 24(7–8):718–722

Shirbhate AD, Deshpande NV, Puri YM (2012) Effect of cryogenic treatment on cutting torque and surface finish in drilling operation with AISI M2 high speed steel. Int J Mech Eng Rob Res 1:1–10

Ramji BR, Narasimha MHN, Krishna M (2010) Performance analysis of cryogenically treated carbide drills in drilling white cast iron. Int J Appl Eng Resc, Dindigul 1:553–560

Dogra M, Sharma VS, Sachdeva A, Suri NM, Dureja JS (2011) Performance evaluation of CBN, coated carbide, cryogenically treated uncoated/coated carbide inserts in finish-turning of hardened steel. Int J Adv Manuf Technol 57:541–553

Thamizhmanii S, Nagib M, Sulaiman H (2011) Performance of deep cryogenically treated and non-treated PVD inserts in milling. J Ach Mater Manuf Eng 49(2):460–466

Yong AYL, Seah KHW, Rahman M (2007) Performance of cryogenically treated tungsten carbide tools in milling operations. Int J Adv Manuf Technol 32:638–643

Ramji BR, Murthy HNN, Krishna M (2010) Performance study of cryo treated HSS drills in drilling cast iron. Int J Eng Sci Technol 2(7):2530–2536

Gill SS, Singh R, Singh H, Singh J (2009) Wear behavior of cryogenically treated tungsten carbide inserts under dry and wet turning conditions. Int J Mach Tools Manuf 49:256–260

SreeramaReddy TV, Sornakumar T, VenkataramaReddy M, Venkatram R (2008) Machining performance of low temperature treated P-30 tungsten carbide cutting tool inserts. Cryogenics 48:458–461

Chang YP, Wang G, Horng JH, Chu LM, Hwang YC (2013) Effects of deep cryogenic treatment on wear mechanisms and microthermal expansion for the material of drive elements. Adv Mater Sci Eng ID945657,7 doi:10.1155/2013/945657

Vadivel K, Rudramoorthy R (2009) Performance analysis of cryogenically treated coated carbide inserts. Int J Adv Manuf Technol 42:222–232

Šolić S, Cajner F, Panjan P (2013) Influence of deep cryogenic treatment of high speed steel substrate on TiAlN coating properties. Mater Werkst 44(12):950–958

Gill SS, Singh J, Singh H, Singh R (2012) Metallurgical and mechanical characteristics of cryogenically treated tungsten carbide (WC–Co). Int J Adv Manuf Technol 58:119–131

Gill SS, Singh H, Singh R, Singh J (2011) Flank wear and machining performance of cryogenically treated tungsten carbide inserts. Mater Manuf Process 26:1430–1441

He H, Han W, Li H, Li D, Yang J, Gu T, Deng T (2014) Effect of deep cryogenic treatment on machinability and wear mechanism of TiAlN coated tools during dry turning. Int J Precis Eng Manuf 15:655–660

Singh LP, Singh J (2012) Effects of cryogenic treatment on the cutting tool durability 3:111–23

Çiçek A, Kara F, Kivak T, Ekici E (2013) Evaluation of machinability of hardened and cryo-treated AISI H13 hot work tool steel with ceramic inserts. Int J Refract Met Hard Mater 41:461–469

Çiçek A, Kıvak T, Ekici E (2013) Optimization of drilling parameters using Taguchi technique and response surface methodology (RSM) in drilling of AISI 304 steel with cryogenically treated HSS drills. J Intell Manuf. doi:10.1007/s10845-013-0783-5

Balasubramanian S, Gupta MK, Singh KK (2012) Cryogenics and its application with reference to spice grinding: a review. Crit Rev Food Sci Nutr 52:781–794

Zhao Z, Hong SY (1992) Cryogenic properties of some cutting tool materials. J Mater Eng Perform 1(5):705–714

Silva FJ, Franco SD, Machado AR, Ezugwu EO, Souza JAM (2006) Performance of cryogenically treated HSS tools. Wear 261:674–685

Fulemova J, Janda Z (2014) Influence of the cutting edge radius and the cutting edge preparation on tool life and cutting forces at inserts with wiper geometry. Process Eng 69:565

Lacalle LNL, Lamikiz A, Larrinoa JF, Azkona I (2011) Machining of hard materials. In: P. Davim (ed) Advanced cutting tools, 11th edn. 33–86

Candane D, Alagumurthi N, Palaniradja K (2013) Tribological studies on deep cryogenic treated AISI T42 high speed steel using response surface methodology. Adv Mater 2:12–22

Radebaugh R (2002) In the Mac Millan encyclopedia of chemistry, cryogenics. Macmillan, New York

Baldissera P, Delprete C (2009) Effects of deep cryogenic treatment on static mechanical properties of 18NiCrMo5 carburized steel. Mater Des 30:1435–1440

Darwin JD, Lal DM, Nagarajan G (2008) Optimization of cryogenic treatment to maximize the wear resistance of 18 % Cr martensitic stainless steel by Taguchi method. J Mater Process Technol 195:241–247

Yong AYL, Seah KHW, Rahman M (2006) Performance evaluation of cryogenically treated tungsten carbide tools in turning. Int J Mach Tools Manuf 46:2051–2056

Poomari A, Mohan B, Rajadurai A, Senthilkumar A (2012) Study on tool life of coated, cryogenically treated and coated and plain cermet cutting tools while machining steel. Eur J Sci Res 85(3):394–407

Preciado M, Bravo PM, Alegre JM (2006) Effect of low temperature tempering prior cryogenic treatment on carburized steels. J Mater Process Technol 176:41–44

Vimal AJ, Bensely A, Lal DM, Srinivasan K (2008) Deep cryogenic treatment improves wear resistance of En 31 steel. Mater Manuf Process 23(4):369–376

Zhirafar S, Rezaeian A, Pugha M (2007) Effect of cryogenic treatment on the mechanical properties of 4340 steel. J Mater Process Technol 186:298–303

Bensely A, Shyamala L, Harish S, Lal DM, Nagarajan G, Junik K, Rajadurai A (2009) Fatigue behaviour and fracture mechanism of cryogenically treated En 353 steel. Mater Des 30:2955–2962

Senthilkumar D, Rajendran I (2011) Influence of shallow and deep cryogenic treatment on tribological behavior of En 19 steel. J Iron Steel Res Int 918(9):53–59

Harish S, Bensely A, Lal DM, Rajadurai A, Lenkey GB (2009) Microstructural study of cryogenically treated En 31 bearing steel. J Mater Process Technol 209:3351–3357

Defu LUO, Shen L (2012) Effect of cryogenic and QPQ compound treatment on the microstructures and performance of high speed steel. Chin J Mech Eng 25:1–6

Seah KHW, Rahman M, Yong KH (2003) Performance evaluation of cryogenically treated tungsten carbide cutting tool inserts. Proc Inst Mech Eng 217(B):29–43

Bal KS (2012) Performance appraisal of cryo‐treated tool by turning operation. Rourkela 25–45

Çiçek A, Uygur I, Kivak T, Altan Zeybek, N (2012) Machinability of AISI 316 austenitic stainless steel with cryogenically treated M35 high-speed steel twist drills. J Manuf Sci Eng Trans ASME134 (6), 061003

Lacalle LNL, Lamikiz A (2009) Machine tools for high performance machining. Springer, New York, pp 75–366

Leskovsek V, Kalin M, Vizintin J (2006) Influence of deep-cryogenic treatment on wear resistance of vacuum heat-treated HSS. Vacuum 80:507–518

Baldissera P (2009) Fatigue scatter reduction through deep cryogenic treatment on the 18NiCrMo5 carburized steel. Mater Des 30:3636–3642

Liu H, Wang J, Yang H, Shen B, Gao S, Huang S (2006) Effect of cryogenic treatment on property of 14Cr2Mn2V high chromium cast iron subjected to subcritical treatment. J Iron Steel Res Int 13(6):43–48

Wang J, Xiong J, Fan H, Yang HS, Liu HH, Shen BL (2009) Effects of high temperature and cryogenic treatment on the microstructure and abrasion resistance of a high chromium cast iron. J Mater Process Technol 209:3236–3240

Bensely A, Senthilkumar D, Lal DM, Nagarajan G, Rajadurai A (2007) Effect of cryogenic treatment on tensile behavior of case carburized steel-815M17. Mater Charact 58:485–491

Dhokey NB, Nirbhavne S (2009) Dry sliding wear of cryo treated multiple tempered D-3 tool steel. J Mater Process Technol 209:1484–1490

Özbek N, Çiçek A, Gülesin M, Özbek O (2014) Investigation of the effects of cryogenic treatment applied at different holding times to cemented carbide inserts on tool wear. Int J Mach Tool Manuf, doi:10.1016/j.ijmachtools.2014.06.007

Gill SS, Singh J, Singh H, Singh R (2011) Investigation on wear behaviour of cryogenically treated TiAlN coated tungsten carbide inserts in turning. Int J Mach Tools Manuf 51:25–33

Ramji BR, Narasimha Murthy HN, Krishna M, Raghu MJ (2010) Performance study of cryogenically treated HSS drills in drilling gray cast iron using orthogonal array technique. Res J Appl Sci Eng Technol 2(5):487–491

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akincioğlu, S., Gökkaya, H. & Uygur, İ. A review of cryogenic treatment on cutting tools. Int J Adv Manuf Technol 78, 1609–1627 (2015). https://doi.org/10.1007/s00170-014-6755-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6755-x