Abstract

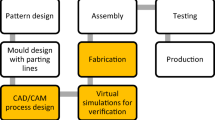

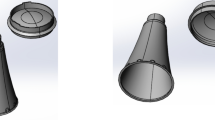

A rapid tooling approach is presented in this article to build an injection mould for low-volume production of plastic parts. This is an indirect tooling method using a rapid prototype model as a casting pattern. A layer of nickel–phosphorous alloy is plated on the casting pattern before it is cast in the aluminium-filled epoxy resin to form a cavity insert. After the removal of the casting pattern, the nickel–phosphorous alloy layer left on the wall of epoxy cavity insert acts as a protective layer to improve the tool life. The insert is installed in a mouldbase for injection moulding experiment. Three plastic parts are tried on the moulds built by this rapid tooling approach. This research has shown that manufacturing an indirect rapid tooling using electroless nickel plating for low-volume production of plastic injection mouldings is feasible for the rapid prototyping models. The cavity insert can be fabricated using commonly available low-cost materials within 48 h. More importantly, the tool life is longer under normal plastic processing conditions and quality mouldings are obtained.

Similar content being viewed by others

References

Ding Y, Lan H, Hong J, Wu D (2003) An integrated manufacturing system for rapid tooling based on rapid prototyping. Robot Comput Integr Manuf 20:281–288

Hilton PD (2000) Rapid tooling technologies and industrial applications. Marcel Dekker Inc, New York. ISBN 0-8247-8788-9

Masood SH (1996) Intelligent rapid prototyping with fused deposition modelling. Rapid Prototyp J 2(1):24–33

Agarwala M, Bourell D, Beaman J, Marcus H, Barlow J (1995) Direct selective laser sintering of metals. Rapid Prototyp J 1(1):26–36

Kodama H (1981) Automatic method for fabricating a three-dimensional plastic model with photohardening polymer. Rev Sci Instrum 52(11):1770–73

Bibb R, Eggbeer D, Evans P (2010) Rapid prototyping technologies in soft tissue facial prosthetics: current state of the art. Rapid Prototyp J 16(2):130–137

Masood SH, Song WQ (2004) Development of new metal/polymer materials for rapid tooling using fused deposition modelling. Mater Des 25:587–594

Tseng AA, Tanaka M (2001) Advanced deposition techniques for free form fabrication of metal and ceramic parts. Rapid Prototyp J 7(1):6–17

Lorber B, Hsiao WK, Hutchings IM, Martin KR (2014) Adult rat retinal ganglion cells and glia can be printed by piezoelectric inkjet printing. Biofabrication 6(1):015001. doi:10.1088/1758-5082/6/1/015001

Gong X, Lydon J, Cooper K, Chou K (2014) Beam speed effects on Ti–6Al–4V microstructures in electron beam additive manufacturing. J Mater Res 29(17):1951–1959

Gong X, Anderson T, Chou K (2014) Review on powder-based electron beam additive manufacturing technology. Manuf Rev 1:1–12

Rahmati S, Dickens P (2007) Rapid tooling analysis of stereo lithography injection moulding tooling. Int J Mach Tools Manuf-Des, Res Appl 47:740–747

Hopkinson N, Dickens P (2000) A comparison between stereolithography and aluminium injection moulding tooling. Rapid Prototyp J 6(4):253–258

Harris RA, Newlyn HA, Dickens PM (2002) Selection of mould design variables in direct stereolithography injection moulding tooling. Inst Mech Eng 216(4):499–505

Ferreira JC (2004) Manufacturing core-boxes for foundry with rapid tooling technology. J Mater Process Technol 155–156:1118–1123

Harris RA, Newlyn HA, Hague RJM, Dickens PM (2003) Part shrinkage anomalies from stereolithography injection mould tooling. Int J Mach Tools Manuf 43:879–889

Gibbons GJ, Hansell RG (2005) Direct tool steel injection mould inserts through the Arcam EBM free-form fabrication process. Assem Autom 25(4):300–305

Antonio JP, Queiros MP, Martinho PG, Bartolo PJ, Antonio SP (2010) Experimental assessment of hybrid mould performance. Int J Adv Manuf Technol 50:441–448

Cheah CM, Chua CK, Ong HS (2002) Rapid moulding using epoxy tooling resin. Int J Adv Manuf Technol 20(5):368–374

Ma S, Gibson I, Balaji G, Hu QJ (2007) Development of epoxy composites for rapid tooling applications. J Mater Process Technol 192–193:75–82

Kovacs JG, Bercsey T (2005) Influence of mold properties on the quality of injection molded parts. Periodica Polytechnica Ser Mech Eng 49(2):115–122

Rossi S, Deflorian F, Venturini F (2004) Improvement of surface finishing and corrosion resistance of prototypes produced by direct metal laser sintering. J Mater Process Technol 148:301–309

Schlesinger M, Paunovic M (2010) Modern electroplating, 5th edn. Wiley, Hoboken

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajaguru, J., Duke, M. & Au, C. Development of rapid tooling by rapid prototyping technology and electroless nickel plating for low-volume production of plastic parts. Int J Adv Manuf Technol 78, 31–40 (2015). https://doi.org/10.1007/s00170-014-6619-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6619-4