Abstract

The integration and combination of known production technologies to one-step-processes is a promising way to make existing processes more efficient and to enable more integrated products. This paper presents two integrative process technologies that are developed by the Institute of Plastics Processing (IKV) and the Surface Engineering Institute (IOT) as part of the Cluster of Excellence “Integrative Production Technologies for High-Wage Countries”. In these processes, metals or metal alloys are applied to an injection moulded part, which results in a new opportunity to create electrical conductivity of plastic articles. The Integrated-Metal-Plastic-Injection-Moulding (IMKS) represents the combination of injection moulding and metal die-casting, allowing the production of plastic parts with integrated conductive tracks in one shot. The In-Mould-Metal-Spraying (IMMS) combines the injection moulding with the thermal spraying of metal. Therefore it is possible to equip electrically insulating plastic parts with metallic coatings and provide an electromagnetic shielding like cast metal parts. In the following both processes are presented and future potentials and challenges are shown.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

In traditional engineering, metals and plastics normally compete with each other (Berneck 2011; Flepp 2012). Nowadays, the growing requirements regarding functionality and complexity of parts often cannot be met by a single material. Hence the hybrid technology, which combines the advantages of different materials within one part, is gaining increased importance. Amongst others the part functionality can be expanded by integrating electrical conductivity or by an improvement of the wear-resistance of the surfaces of plastics parts. Manifold applications arise in the fields of electronics as well as in the automotive industry, e.g. connectors or parts with selectively conductive areas (Drummer and Dörfler 2007).

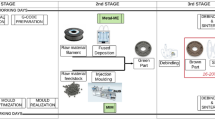

Today, various technologies are capable of producing plastic/metal hybrid parts (Fig. 10.1).

One possible process is the injection moulding of electrically conductive polymer melts. Therefore electrical conductive materials like metal fibres, carbon black or carbon nano tubes are introduced as fillers/additives by the compounding (Pfeiffer 2005; Pflug 2005). The hybrid compounds can be processed on regular injection moulding machines; however the high filler content limits the flowability, thus requiring an adapted part design. Also the electrical properties of pure metals cannot be reached (Pfeiffer 2005).

Another way of metalising is the coating of plastic parts. For example electroplating, ion plating, chemical vapour deposition, thermal spraying or with physical vapour deposition can be used to metalise prefabricated plastic parts (Grob et al. 2003; Brosig 1996). Each process needs at least one additional process step and equipment. In addition the coating has a given thickness which leads to dimensional inaccuracy of the part. Especially the electroplating, often applied since the 1960s, is limited to special polymers, for example ABS, PC, PA (Kanani 2009; Chanda and Roy 2007).

The in-mould-assembly process comprises a preceded production of the metal parts. The prefabricated metal parts are subsequently placed in the injection mould to be overmoulded by the plastic melt. The overmoulding of metallic films is often used in terms of improving the optics and haptic (cool-touch-effect). Overmoulded grids are applied to improve the electromagnetic compatibility (EMC) of the parts. The maximum degree of deformation of the overmoulded film or grid depends on the elasticity of the used metal, which limits the geometrical freedom. In each case especially the production of the metal component is characterised by additional expensive and complex procedures like bending, stamping, drilling etc. Also the inserted material has to be fabricated and placed into the mould, increasing the cost for the automation and the supply of the semi-finished materials.

Summarised, the various processes have disadvantages resulting from limitations in productivity, processing properties or the level of achievable geometrical part complexity.

Within the scope of the Cluster of Excellence “Integrative Production Technology for High-Wage Countries”, two new approaches are developed to overcome the described disadvantages. The injection moulding of plastics and pressure die-casting of metal on one side, and the injection moulding and thermal spraying of metal on the other side are two new integrated processes for the production of plastic/metal hybrid parts.

2 Integrated Metal/Plastics Injection Moulding (IMKS)

The Integrated Metal/Plastics Injection Moulding (IMKS) is constantly developed since 2007. The IMKS uses the established and proven method of the multi-component technology as the fundament to combine the plastics injection moulding with the metal pressure die-casting to one integrated process (Fig. 10.2). With the IMKS it is possible to on-mould conductive tracks on a primarily injection moulded plastics carrier. The alloys used on the basis of tin have high electrical conductivities and are already established in the field of lead-free soldering for electronic applications. In addition, the melt temperatures of these alloys, within a range between 200–250 °C, fit into the temperature range of the used engineering thermoplastics (e.g. PA6.6 or PBT). The essential development cores for the technical implementation of the IMKS are the appropriate choice of materials, the development of an injection technology for reproducible processing of the low-melting metal alloys and a mould technology to produce ready-to-use electronic parts with integrated functions.

2.1 Device for the Processing of Low-Melting Metal Alloys

While accessory units as an extension of standard machines to multi-component injection moulding machines are state of the art since the early 1990s, there is no similar solution in the field of metal pressure die-casting. For this reason, based on studies at the IKV and supported by the Krallmann Plastics Processing Gmbh, Hiddenhausen, Germany, a compact accessory unit for processing of low melting metal alloys has been developed. It can be integrated into the injection moulding process via core pull control (Hopmann et al. 2011, 2012, 2013). Based on the hot chamber die casting, the accessory unit utilises a plunger which is completely immersed in the liquid metal. The metal alloy is supplied in commercial bar form in the open, electrically heated melting pot and melted by heat conduction. The dosing is done by retracting the injection plunger. In this case, an overflow hole is released, whereby molten metal flows into the injection cylinder by gravity. Figure 10.3 shows the operation of the metal die-casting unit schematically.

2.2 IMKS Mould Technology

The IKV supported by the Krallmann Plastics Processing GmbH developed a 3-station index plate mould which allows the processing of two plastics and one low melting metal alloy in one mould and one machine (Fig. 10.4).

The molten metal and two different plastic melts are supplied to the respective cavities via hot runner valve gate nozzles. The transfer between the individual stations is done via a servo-electric powered index plate. The index plate technology has proved to be the most appropriate mould technology to produce complex multi-component metal/plastic components due to their geometrical freedom on the closing and nozzle side.

By using this mould technology, as presented on the K-show 2010 in Düsseldorf, Germany, the fully automated production of a three component sports glasses with integrated conductive tracks for the heating and defogging of the lenses has been realised (Michaeli et al. 2010). The new process offers high reproducibility and short cycle times which qualifies the new technique for industrial production. The glasses were moulded within a cycle time of 80 s. Thereby a three dimensional conductive track with varying cross-sectional area was manufactured featuring high aspect ratios and the possibility of a direct contacting of metallic inserts. Additionally presented on the Fakuma-show 2012 in Friedrichshafen, Germany, a second demonstrator in the form of a desk lamp shows the possibility of the direct in-mould solder like connecting the conductive tracks with a LED (Doe 2012). The LED is already integrated into the part in the process. Thus no assembly is required at all to produce the lamp (Fig. 10.5).

2.3 Influence of Variothermal Mould Temperature Control on the Achievable Conductive Track Length

In order to provide complex conductor path structures while minimising the material consumption of the metal alloy, conductor paths as filigree as possible should be designed, for example with a diameter of less than 1.5 mm2 and a length of several hundred millimeters. To achieve the flow length by using the IMKS the use of a variothermal mould temperature control is expected to be advantageous. By local and close-to-cavity heating of the mould in the area of the conductor paths prior to the metal alloy injection and rapid cooling after the injection, it is possible to produce such conductor paths and other filigree structures without thermally damaging the plastics carrier.

For the investigation of the flowability of the metal alloy a meandering flow channel course is milled into a polyamide 6 carrier plate using a CNC-driven milling machine and different cross-sectional dimensions (Fig. 10.6). The carrier plate has a thickness of 4 mm. The flow channel is filled with the low melting metal alloy in an experimental mould.

To achieve a variothermal process control an inductor is moved into the open mould via a 6-axis robot of the KUKA AG, Augsburg, Germany. Subsequently, the surface of the nozzle half is heated in the region of the conductor paths by the inductive alternating field, leading to a temperature above the melting point of the metal alloy of approximately 230 °C during the injection phase. The carrier plate is then manually inserted into the mould cavity on the closing half, the inductor is swivelled out from the mould, the mould closes and the metal alloy is injected.

An increase of the flow length of the metal component due to the variothermal mould heating can be observed for all cross-sectional dimensions (Fig. 10.6, right). The high mould wall temperature leads to a delayed solidification, resulting to a doubling of the achievable flow length especially for cross-sections below 1 × 1 mm2. It is also clear that the results of the samples prepared with variothermal mould temperature control have a larger scatter. The reason for this is not yet fully understood, but subject to further investigation currently ongoing. Since the components are inserted manually, the slightly different retention time of the plastics carrier plates in the mould can be a source of variation.

3 In-Mould-Metal-Spraying (IMMS)

The In-Mould-Metal-Spraying (IMMS) is another integrated process designed to simplify the production of metallised plastics components. At the same time it opens up new possibilities in product development. The IMMS enables the fabrication of metallic coatings onto the surface of plastics components, which can be used in the electrical industry. Certain requirements on these components regarding the haptic characteristics (cool-touch-effect) and electromagnetic shielding (EMC) can be fulfilled with metal coatings. With this method, under development since 2012 by the IKV and IOT at the RWTH Aachen University, at first a metal coating is applied inline to certain areas of the cavity surface of an injection mould via thermal spraying. In the next step the metal layer is back-moulded with plastic. The metal layer is thereby transplanted to the plastics component, similar to the in-mould labelling process. Metal layer and plastic are then demoulded as a plastic component with integrated partially metallised surface (Fig. 10.7).

3.1 Selection of Materials and Thermal Spraying Process

The thermal spraying process has to fulfil special requirements to enable the integrated process. One key question is, if the thermal sprayed coating can be separated from the mould surface during injection moulding. Therefore, in particular the adhesive strength between metal coating and the overmoulded plastics has to exceed the adhesive strength between metal coating and mould surface. Simultaneously the adhesion of the metal coating to the mould surface has to be sufficiently high to withstand the emerging shear stress during the injection moulding process. Also the surface of the mould shall not be destroyed through the thermal spraying process to enable a continuous reproducible production.

Subject to these conditions the wire arc spraying process is chosen for the tests (Fig. 10.8).

The particle velocities in wire arc spraying process are, in comparison to the other conventional thermal spraying processes relatively low (50–100 m·s−1). Thereby, a low abrasion of the mould surface is expected. Another conventional thermal spraying process, which exhibits similar particle velocities, flame spraying, cannot reach deposition rates reached by wire arc spraying. The cooler deposit characteristic of wire arc spraying minimizes the substrate heating common with other thermal spray processes; hence processes advantages regarding the substrate temperatures (Tucker 2013). Zinc is chosen to be the deposition material for the metallic component. Zinc coatings are widely used for corrosion protection, often for steel substrates. Moreover the compatibility to different plastic components is given in earlier experiments where the zinc coating was brought onto the plastic surface, using the wire arc spraying (Bobzin et al. 2011).

Without a special surface treatment of the used cavity insert it was possible to transfer >95 % of the zinc coating onto the plastics part (Fig. 10.9). The milling marks provide enough adhesion.

Through application of masking upon the mould surface before the thermal spraying process, partial transplantation of the selected areas onto the plastics component can be realised. This extends the degree of freedom during the metallisation process. As mentioned before, the adhesion of the metal coating to the mould surface must be carefully adjusted to fulfil the requirements regarding the transferability of the coatings in the IMMS process. A key factor hereby is the roughness of the mould surface. In order to achieve the intact transplantation of the coatings, different roughening methods and parameters have been investigated and analysed (Bobzin et al. 2014). As a result, together with the usage of masking methods, selective transplantation of the metal coating was realised. The transplanted coating was intact (Fig. 10.10).

4 Conclusion and Outlook

The presented process combinations can provide benefits in terms of a more efficient production of plastic components with electrically conductive elements. Both methods, developed at the Cluster of Excellence “Integrative Production Technology for High-Wage Countries” at RWTH Aachen University, increase the added value of electrical products, at the same time rationalise the production and thus help companies of high-wage countries to remain competitive in the future.

The Integrated Metal/Plastics Injection Moulding (IMKS), evolved over the last years, enables the production of electrical and electronic parts in extremely short cycle times compared to existing multi-stage process alternatives. The short process chain is made possible by the transfer of the underlying technologies in a one-step process, in which all the necessary steps are controlled by one machine. The studies also indicate the possibility of direct contacting of electrical inserts inside the mould, which in turn saves additional process steps. The demand for filigree conductor paths can be satisfied by the use of variothermal mould temperature control. The previous studies already arouse the interest of industrial companies. For example, cooperation between the IKV and the OSRAM GmbH, Munich, Germany, could be established to investigate the contacting of a circuit board equipped with a LED with the metal alloy for optical applications. In future studies, the achievable long-term stability of the plastic/metal hybrids will be investigated particularly under the influence of media and temperature loads.

The studies on the newly developed In-Mould-Metal-Spraying (IMMS) show a remarkable potential of progress. A surficial application of the metal coating through the combination of wire arc spraying and injection moulding can extend the application areas of plastic components to the electronic industry by utilizing these components with better electromagnetic shielding and haptic characteristics. In further studies, a new mould technology which enables the production of the IMMS parts in a single-step process shall be investigated. Well-known mould technologies from the multi-component injection moulding like e.g. transfer processes using rotary mechanism or robotic transfer (Michaeli and Johannaber 2004; Michaeli and Lettowsky 2005) will be adapted to the new process.

References

Berneck J (2011) Kunststoff statt Metall. Kunststoffe 102 (9):109–111

Bobzin K, Michaeli W, Brecher C, Kutschmann P (2011) Integrative Produktionstechnik für Hochlohnländer. Springer-Verlag, Heidelberg

Bobzin K, Öte M, Linke TF, Schulz C, Hopmann C, Wunderle J (2014) Integration of Electrical Functionality by Transplantation of Cold Sprayed Electrical Conductive Cu Tracks via Injection Moulding. In: International Thermal Spray Conference 2014, Barcelona, 2014. DVS-Berichte, vol 302

Brosig E (1996) Chemisch-Kupfer sorgt für eine schützende Haut. EMV-Schutz: Kunststoffgehäuse selektiv metallisieren. Industrieanzeiger 43:44–46

Chanda M, Roy K (2007) Plastics Technology Handbook. CRC Press, Taylor & Francis Group, Boca Raton

Doe J (2012) Erfolgreiche Fakuma für KraussMaffei, Netstal und KrausMaffei Berstorff. München

Drummer D, Dörfler R (2007) Mechatronik mit Kunststoffen–Herausforderungen auf dem Weg vom Werkstoff zur Baugruppe. Paper presented at the Spritzgießen 2007, Düsseldorf

Flepp A (2012) Wirschaftlicher als Metall. Kunststoffe 102 (8):73–75

Grob W, Müller K, Habiger E (2003) EMC Kompendium 2003. publish-industry, München

Hopmann C, Neuß A, Wunderle J (2011) Hybrid multi-component injection moulding for electro- and electronic applications. Paper presented at the Proceedings of the 27th World Congress of the Polymer Processing Society, Marrakesh, Marokko

Hopmann C, Neuß A, Wunderle J (2012) Integrierte Fertigung von E&E-Bauteilen durch hybrides Mehrkomponenten-Spritzgießen. In: Umdruck zur VDI-Jahrestagung Spritzgießen Baden-Baden, 2012

Hopmann C, Neuß A, Wunderle J (2013) Fertigung von komplexen Elektronikkomponenten durch Integriertes Metall/Kunststoff-Spritzgießen (IMKS). Paper presented at the VDI-Fachtagung Polytronics, Frankfurt am Main

Kanani N (2009) Galvanotechnik: Grundlagen: Verfahren und Praxis einer Schlüsseltechnologie. Carl Hanser Verlag, München, Wien

Michaeli W, Grönlund O, Neuss A, Wunderle J, Gründler M (2010) New Process for Plastic Metal Hybrids. Kunststoffe International 9 (2):102–105

Michaeli W, Johannaber F (2004) Handbuch Spritzgießen. Carl Hanser Verlag, München, Wien

Michaeli W, Lettowsky C (2005) Mehrkomponentenspritzgießen. Verfahren und Möglichkeiten. In: Umdruck zur VDI-Fachtagung Spritzgießen, Baden-Baden, 2005

Pfeiffer B Elektrisch leitfähige Kunststoffe. In: OTTI Technik-Kolleg, Regensburg, 2005

Pflug G (2005) Kunststoffgehäuse abschirmen. Kunststoffe 95 (2):22–27

Tucker RC (2013) Thermal Spray Technology, vol 5A. ASM Handbook. ASM International, Materials Park

Acknowledgments

The depicted research referring to the Integrated Metal/Plastics Injection Moulding (IMKS) and the In-Mould-Metal-Spraying (IMMS) has been funded by the German Research Foundation (DFG) as part of the program Cluster of Excellence “Integrative Production Technology for High-Wage Countries” at the RWTH Aachen.

We would like to extend our thanks to the DFG, the German Bundesministerium für Wirtschaft und Energie (BMWi). We also thank all companies who have supported these research projects through the provision of materials, machinery and other resources.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is distributed under the terms of the Creative Commons Attribution Noncommercial License, which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Copyright information

© 2015 The Author(s)

About this paper

Cite this paper

Hopmann, C., Bobzin, K., Weber, M., Öte, M., Ochotta, P., Liao, X. (2015). IMKS and IMMS—Two Integrated Methods for the One-Step-Production of Plastic/Metal Hybrid Parts. In: Brecher, C. (eds) Advances in Production Technology. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-12304-2_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-12304-2_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-12303-5

Online ISBN: 978-3-319-12304-2

eBook Packages: EngineeringEngineering (R0)