Abstract

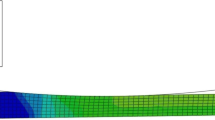

In rolling of wide strip, longitudinal compressive stresses develop as a result of nonuniform deformation along the plate width, which enhance long-shape wave. Theoretical assessment of these stresses and factors affecting their magnitude and distributions are not emphasized in existing solutions, since most of the solutions are based on the assumption of plane strain along the entire width. In present investigation, a 3D model of cold rolling process of steel is simulated using the finite element method (FEM) to analyze the flow of material and stresses developed in steady-state wide strip cold rolling of plate with nonuniform thickness profile. The results show that the transition from a flat state to bad shape for specific ratio of output thickness to the width of plate occurs as a result of thickness profile changes, and it is also shown that the critical crown ratio changes in edge wave development are smaller than the middle one.

Similar content being viewed by others

References

Wang XD, Li F, Wang L, Zhang XL, Dong LJ (2012) Development and application of roll contour configuration in temper rolling mill for hot rolled thin gauge steel strip. Ironmak Steelmak 39:163–170

Shigeru T, Yoichi K, Kenji M (2009) Flatness control system of cold rolling process with pneumatic bearing type shape roll. Eng rev 42:54–60

Wistreich JG (1968) Control of strip shape during cold rolling. J Iron Steel Inst 206:1203–1206

Shohet KN, Townsend NA (1968) Roll bending methods in crown control in four-high plate mills. J Iron Steel Inst 206:1088–1098

Sabatini B, Yeomans KA (1968) An algebra of strip shape and its application to mill scheduling. J Iron Steel Inst 206:1207–1213

Tarnopolskaya T, Hog FR (1998) An efficient method for strip flatness analysis in cold rolling. Math Eng Ind 7:71–95

Komori K (1998) Analysis of cross and vertical buckling in sheet metal rolling. Int J Mech Sci 40:1235–1246

Fischer FD, Rammerstorfer FG, Friedl N, Wieser W (2000) Buckling phenomena related to rolling and leveling of sheet metal. Int J Mech Sci 42:1887–1910

Fischer FD, Rammerstorfer FG, Friedl N (2003) Residual stress-induced center wave buckling of rolled strip metal. ASME J Appl Mech 70:84–90

Fischer FD, Rammerstorfer FG, Friedl N (2005) A study on the buckling behavior of strips and plates with residual stresses. Steel res int 76:327–335

Zhou Z, Lam Y, Thomson PF, Yuen DDW (2007) Numerical analysis of the flatness of thin, rolled steel strip on the run out table. J Eng Manuf 221:241–254

Townsend NA, Shohet KN (1971) Flatness control in plate rolling. J Iron Steel Inst 209:769–775

Hu YU, Gong DY, Jiang ZY, Xu JZ, Zhang DH, Liu XH (2009) Effect of initial crown on shape of hot rolled strip. J Iron Steel Res Int 16:32–34

Malik AS, Grandhi RV (2008) A computational method to predict strip profile in rolling mills. J Mater Process Technol 206:263–274

Wang X, Yang Q, He A (2008) Calculation of thermal stress affecting strip flatness change during run-out table cooling in hot steel strip rolling. J Mater Process Technol 207:130–146

Galantucci LM, Tricarico L (1999) Thermo-mechanical simulation of a rolling process with an FEM approach. J Mater Process Technol 93:494–501

Mori K, Osakada K, Oda T (1982) Simulation of plane-strain rolling by the rigid-plastic finite element method. Int J Mech Sci 24:519–527

Hwu Y, Lenard JG (1988) A finite element study of at rolling. Trans ASME J Eng Mater Technol 110:22–26

Yarita I, Mallett RL, Lee EH (1988) Stress and deformation analysis of plane strain rolling process. Steel Res 56:231–255

Fang G, Lei LP, Zeng P (2002) Three-dimensional rigid-plastic finite element simulation for the two-roll cross-wedge rolling process. J Mater Process Technol 129:245–249

Jiang ZY, Tieu AK, Zhang XM, Lu C, Sun WH (2003) Finite element simulation of cold rolling of thin strip. J Mater Process Technol 140:542–547

Zhou Z, Lam Y, Thomson PF, Yuen DDW (2007) Predicting quarter-buckling and herringbone buckling in rolled strip. J Eng Manuf 221:143–150

ABAQUS Documentation. Reference document for ABAQUS/CAE, including ABAQUS/Viewer., Ver. 6.9

Altan T, Gegel HL (1983) Metal forming fundamental and application. ASM, Metal Park, OH 44073, Carner, Pub, Service, Inc, USA

Bland DR, Ford H (1948) The calculation of roll force and torque in cold strip rolling with tensions. Proc IME 159:144–153

Montmitonne P (2006) Hot and cold strip rolling processes. Comput Methods Appl Mech Eng 195:6604–6625

Dixon AE, Yuen WY (2008) A physical based method to predict spread and shape during flat rolling for real-time application. Steel Res Int 79:287–296

Cao J, Zhang J, Kong N, Mi K (2010) Finite element analysis of strip and rolling mills. Finite Element Analysis, Sciyo, Croatia, pp 561–588

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

Rights and permissions

About this article

Cite this article

Moazeni, B., Salimi, M. Investigations on relations between shape defects and thickness profile variations in thin flat rolling. Int J Adv Manuf Technol 77, 1315–1331 (2015). https://doi.org/10.1007/s00170-014-6544-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6544-6