Abstract

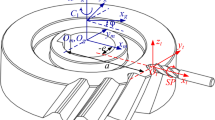

In today’s studies, it is observed that spur gears can be manufactured by vertical-spindle CNC milling machines unlike conventional manufacturing methods. To this end, two different approaches have been developed, which are vertical and axial manufacturing methods. In this study, concave-convex gear wheels are the first time correctly manufactured by using the vertical cutting method. The manufacture time of these gears are determined. This time is compared with spur gear manufacturing time which they manufactured by conventional machines. When these gears are manufactured, the parametric equations of involute curve are formed in order to create the 3D model required for manufacturing concave-convex gear wheels. 3D model is created based on these equations and the manufacturing program is written. The manufacturing times are calculated by manufacturing these gears based on various parameters such as the module, number of teeth, tooth width, depth of cut, and cutting angle of the gear. The size of the manufactured gears has been identified. Then, the measured values were found to be consistent with the calculated values. It is detected that the manufacturing times increase along with the increase of module values as well as increasing number of teeth and cutting angle.

Similar content being viewed by others

References

Tsay CB, Liu WY, Yi-Chen C (2000) Spur gear generation by shaper cutters. J Mater Process Technol 104:271–279

Kim JD, Kim DS (1997) Development of software for the design of a pinion cutter. J Mater Process Technol 68:76–82

Hefeng B, Savage M, Knorr RJ (1985) Computer modelling of rack-generated spur gears. Mech Mach Theory 20(4):351–360

Uzun M, Ozel, C (2011) Curved profiled cylindrical ınvolute gears research on design with catia CAD-CAM program, IATS’11, pp. 16–18

Vijayakar SM, Sarkar DR, Houser DR (1998) Gear tooth profile determination from arbitrary rack geometry. Gear Technol 6:18–30

Kuang JH, Chen WL (1996) Determination of tip parameters for the protuberance preshaving cutters, Mech Mach Theory, pp.839–849

Chang SL, Tsay CB, Nagata S (1997) A general mathematical model for gear generated by CNC hobbing machine. Trans ASME J Mech Des 119:108–113

Ozek C, Ozel C (2002) Manufacture of spur gears using macro programs with vertical machining center CNC milling machines. J Mach Eng 512:43–49

Ozel C (2012) A study on cutting errors in the tooth profiles of the spur gears manufactured in CNC milling machine. Int Adv Manuf Technol 59:243–251

Ozek C, Savas V (2003) The machining of rack in cnc milling machine with vertical centered, Research in the eastern Anatolia region

Ozel C, Inan A, Ozler L (2005) An investigation on manufacturing of the straight bevel gear using end mill by CNC milling machine. J Manuf Sci Eng Trans ASME 127:503–511

Sandeep M, Snaka VB, Houser DR (1988) Gear tooth profile determination from arbitrary rack geometry. Gear Technol pp.18–30

Huston RL, Mavriplis D, Oswald FB (1989) Computer aided design of spur gear teeth, 5th ASME International Power Transmission and Gearing Conference, pp. 539–545

Uzun M, Inan A (2014) Manufacturig the new type concav-convex profile involute gears modeled by CAD-CAM in CNC milling machines Journal of the Brazilian Society of Mechanical Sciences and Engineering

Talón JLH, Ortega JCC, Gómez CL, Sancho ER, Olmos EF (2010) Manufacture of a spur tooth gear in Ti-6Al-4 V alloy by electrical discharge. Comput Aided Des 42:221–230

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uzun, M. The investigation on manufacturing time of a new type concave-convex gear by a CNC milling machine. Int J Adv Manuf Technol 77, 1275–1280 (2015). https://doi.org/10.1007/s00170-014-6541-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6541-9