Abstract

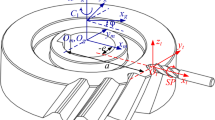

In this study, the cutting errors in the tooth profile of the spur gears which are manufactured by end mill according to radial cutting method in three-axis CNC milling machine are investigated. According to this method, a mathematical approach in order to investigate the cutting errors of the tooth profile is presented. Then, mathematical expressions determining the error quantity in the tooth profile curve are derived by using this approach, and a programme is developed in the MATLAB. Parameters such as module (m), tooth number (N), pressure angle (∅) and cutting angle (α m ) in the programme are changed, and the cutting errors of the involute tooth profile according to the obtained results are interpreted graphically. As a result, it is seen that the cutting errors in the involute curve increase according to increments of m, N, ∅ and α m .

Similar content being viewed by others

References

Suh SH, Lee ES, Kim HC, Cho JH (2002) Geometric error measurement of sipiral bevel gears using a virtual gear model for STEP-NC. Mach Tools Manuf 42:335–342

Tamura H, Liu Z (1997) Measurement of helical gear using coordinate measuring machine. J Jpn Soc Mech Eng 63:252–258

Suhunmugam M, Narayana S, Jayapraksh V (1998) Establishing gear tooth surface geometry and normal deviation: part 1—cylindrical gears. J Mech Mach Theory 33(5):517–524

Suhunmugam M, Narayana S, Jayapraksh V (1998) Establishing gear tooth surface geometry and normal deviation: part 2—bevel gears. J Mech Mach Theory 33(5):525–534

Ming-Haung T, ShengFeng L, Ying-Chien T (1998) Diagnoses of the operational errors of a threaded-wheel grinder in the grinding of spur gears kinematic transmission errors. J Mater Process Technol 75:190–197

Litvin FL et al (1983) Kinematic precision of gear trains. J Mech Transm Autom Des 105(3):317–326

Litvin FL et al (1995) Computerized design and generation of low-noise helical gears with modified surface topology. J Mech Des 117(2):254–261

Kin V (1994) Computerized analysis of gear meshing based on coordinate measurement data. J Mech Des 116(3):738–744

Litvin FL et al (1995) Computerized simulation of transmission errors and shift of bearing contact for face-milled hypoid gear drive. J Mech Des 117(2):262–268

Fong Z-H, Tsay C-B (1992) Kinematic optimization of spiral bevel gears. J Mech Des 114(3):498–506

Uematsu S (2002) Effect of variation of angular velocity in gear rolling process on profile error. Precision engineering. J Int Soc Precis Eng Nanotechnol 26:425–429

Yann H, Michèle G, de Vaujany JP (2006) Numerical simulation and optimisation of worm gear cutting. Mech Mach Theory 41:1090–1110

Özel C, İnan A, Özler L (2005) An investigation on manufacturing of the straight bevel gear using end mill by CNC milling machine. J Manuf Sci Eng Trans ASME 127:503–511

Kawasaki K, Shinma K (2009) Accuracy measurement and evaluation of straight bevel gear manufactured by end mill using CNC milling machine. Trans ASME J Mech Des 131:011001–011008

Kawasaki K, Shinma K (2007) Accuracy of straight bevel gear by end mill using CNC milling machine. ASME Int Des Eng Tech Conf/Comput Inf Eng Conf 7:767–774, 2008

Kawasaki K, Shinma K (2008) Design and manufacture of straight bevel gear for precision forging die by direct milling. Mach Sci Technol 12:170–182

Kawasaki K, Shinma K (2006) Direct milling of straight bevel gear for precision forging die. 8th International Conference on Progress of Machining Technology, Proceedings, pp 325–328

Talón JLH, Ortega JCC, Gómez CL, Sancho ER, Olmos EF (2010) Manufacture of a spur tooth gear in Ti-6Al-4V alloy by electrical discharge. Comput Aided Des 42:221–230

Radzevich SP (2007) On the accuracy of precision involute hobs: an analytical approach. J Manuf Process 9 No. 2:121–136

Das AK (1999) Technological heredity in spur gear manufacturing. J Mater Process Technol 91:66–74

Li S (2007) Effects of machining errors, assembly errors and tooth modifications on loading capacity, loaded-sharing ratio and transmission error of a pair of spur gears. Mech Mach Theory 42:698–726

Özel C (2011) Research of production times and cutting of the spur gears by end mill in CNC milling machine. Int J Adv Manuf Technol. 54:203–213

Juvinall RC, Marshek KM (1991) Fundamentals of machine component design, 2nd edn. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özel, C. A study on cutting errors in the tooth profiles of the spur gears manufactured in CNC milling machine. Int J Adv Manuf Technol 59, 243–251 (2012). https://doi.org/10.1007/s00170-011-3475-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3475-3