Abstract

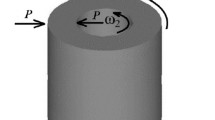

The present article is focused on the rolling of powder tapes. A mathematical model of rolling a powder core in a metal cover is developed based on splitting a consolidation zone into a final set of elementary volumes. The main computational approach is based on the joint solution of the condition of static balance of the elementary volume and the condition of plasticity of porous materials in tension in a final and differential form. During experimental studies, the influence of cover thickness on the course of rolling powder materials is established. Thus, the more cover thickness, the higher its rigidity and elastic deflection. It reduces the extent of the deformation center, power parameters of the process, and deformation of the powder component. Also, the parameters of physical–mechanical properties of powder materials which enter into a condition of plasticity for porous materials were investigated.

Similar content being viewed by others

References

Amirkhanlou S, Jamaati R, Niroumand B, Toroghinejad MR (2011) Manufacturing of high-performance Al356/SiCp composite by CAR process. Mater Manuf Process 26:902–907. doi:10.1080/10426914.2011.577879

Arora HS, Singh H, Dhindaw BK (2012) Composite fabrication using friction stir processing—a review. Int J Adv Manuf Technol 61(9–12):1043–1055. doi:10.1007/s00170-011-3758-8

Chandramouli R, Pandey KS, Kandavel TK, Ashokkumar T, Shanmugasundaram D (2007) Influence of material flow constraints during cold forming on the deformation and densification behaviour of hypoeutectoid P/M steel ring preforms. Int J Adv Manuf Technol 31(9–10):926–932. doi:10.1007/s00170-005-0272-x

Chigarev VV, Gavrish PA, Gribkov EP (2012) Investigation of the process of drawing flux-cored wire for welding copper to steel. Weld Int 26(9):718–722. doi:10.1080/09507116.2011.653152

Chigarev VV, Gavrish PA, Gribkov EP (2014) Improving the technological conditions of drawing flux-cored welding wires. Weld Int 28(1):59–61. doi:10.1080/09507116.2013.796655

Chigarev VV, Belik AG, Gribkov EP, Gavrish PA (2014) Mathematical model of rolling of powder tape. Svarochnoe Proizvodstvo 1(950):21–26 (in Russian)

Chitkara NR, Liaghat GH (2001) Working pressure, deformation modes and fracture in open-piercing of cylindrical disks made of compacted sintered aluminium powder. Int J Adv Manuf Technol 17(12):889–909. doi:10.1007/s001700170100

Danil’chenko BV (1989) Surfacing wear–self-protective powder. Autom Weld 5:38–41 (in Russian)

Drujanov BA (1989) Applied theory of plasticity porous materials. Mechanical Engineering. p. 168 (in Russian)

Es-Saheb MH, Albedah A, Benyahia F (2011) Diametral compression test: validation using finite element analysis. Int J Adv Manuf Technol 57(5–8):501–509. doi:10.1007/s00170-011-3328-0

Fu MW, Chan WL (2013) A review on the state-of-the-art microforming technologies. Int J Adv Manuf Technol 67(9–12):2411–2437. doi:10.1007/s00170-012-4661-7

Gribkov EP, Kulik AM (2000) The stress–strain state of the rolling two-layer powder materials, one layer of which is monometal. Udoskonalennya protsesіv ta obladnannya obrobki tiskom u mashinobuduvannі ta metalurgіi. Kramatorsk–Slov’yansk, pp. 138–141 (in Russian)

Gribkov EP, Danilyuk VА (2013) Influence of a cover form on geometrical and power parameters at rolling a powder electrode tape. Materials working by pressure. Кramatorsk 1(33):226–233 (in Russian)

Gogaev KA, Kalutskii GY, Voropaev VS (2013) Contact stresses in the deformation zone and average pressure during asymmetric rolling of metal powders. Powder Metall Met C+ 52(3–4):126–131. doi:10.1007/s11106-013-9504-z

Gogaev KA, Voropaev VS, Kalutskii GY, Podrezov YN, Verbilo DG, Koryak OS (2012) Production of titanium powder sheets by asymmetric rolling. Powder Metall Met C+ 9–10(487):11–23. doi:10.1007/s11106-013-9462-5

Guigon P, Simon O (2003) Roll press design—influence of force feed systems on compaction. Powder Technol 130:257–264. doi:10.1016/S0032-5910(02)00223-1

Hirohata T, Masaki S, Shima S (2001) Experiment on metal powder compaction by differential speed rolling. J Mater Process Technol 111:113–117. doi:10.1016/S0924-0136(01)00492-7

Hrairi M, Chtourou H, Gakwaya A, Guillot M (2011) Modeling the powder compaction process using the finite element method and inverse optimization. Int J Adv Manuf Technol 56(5–8):631–647. doi:10.1007/s00170-011-3211-z

Kailas SV (2009) Influence of friction during forming processes—a study using a numerical simulation technique. Int J Adv Manuf Technol 40(11–12):1067–1076. doi:10.1007/s00170-008-1425-5

Karimi HR, Djokoto SS (2012) Instrumentation and modeling of high-pressure roller crusher for silicon carbide production. Int J Adv Manuf Technol 62(9–12):1107–1113. doi:10.1007/s00170-011-3871-8

Katashinskii VP, Shtern MB (1983) Stress–strain state of powder being rolled in the densification zone. I. Mathematical model of rolling in the densification zone. Powder Metall Met Ceram 22(11):882–885. doi:10.1007/BF00805540

Katashinskii VP, Shtern MB (1983) Stress–strain state of powder being rolled in the densification zone. Powder Metall Met Ceram 22(12):972–976. doi:10.1007/BF00802421

Keshavarz S, Khoei AR, Molaeinia Z (2013) Genetic algorithm-based numerical optimization of powder compaction process with temperature-dependent cap plasticity model. Int J Adv Manuf Technol 64(5–8):1057–1072. doi:10.1007/s00170-012-4053-z

Kuleshov IE (1989) The method of computing power parameters of rolling bimetallic materials from powders. Steel 9:90–93 (in Russian)

Kumar S, Sharma V, Choudhary AKS, Chattopadhyaya S, Hloch S (2013) Determination of layer thickness in direct metal deposition using dimensional analysis. Int J Adv Manuf Technol 67(9–12):2681–2687. doi:10.1007/s00170-012-4683-1

Lebedev GA, Krasovskiy VN (1973) Rolling and calendering. Chemistry, p. 55 (in Russian)

Makarov RA, Ranskiy AV, Borkunsky GH (1975) Strain measurement in engineering. Mechanical Engineering, p. 268 (in Russian)

Mori K, Osakada K (1987) Analysis of the forming process of sintered powder metals by rigid-plastic finite-element method. Int J Mech Sci 29(4):229–238. doi:10.1016/0020-7403(87)90037-3

Murata Y, Yuasa E, Tanaka M (2009) Experimental analysis of metal flow and strain distribution in rolling of Sn–Pb powder. J Solid Mech Mater Eng Spec Issue Recent Adv Mater Process 3(2):167–177. doi:10.1299/jmmp.3.167

Musikhin AM (1988) Determination of the velocity field in the rolling of porous materials. Powder metall Met Ceram 27(5):335–339. doi:10.1007/BF00797673

Narayan S, Rajeshkannan A (2013) Influence of carbon content on workability behavior in the formation of sintered plain carbon steel preforms. Int J Adv Manuf Technol 64(1–4):105–111. doi:10.1007/s00170-012-4002-x

Petrosyan GL (1979) The deformation theory of plasticity of porous materials. Izvestiya vuzov Mech Eng 11:5–8 (in Russian)

Perig AV, Laptev AM, Golodenko NN, Erfort YA, Bondarenko EA (2010) Equal channel angular extrusion of soft solids. Mat Sci Eng A-Struct 527(16–17):3769–3776. doi:10.1016/j.msea.2010.03.043

Perig AV, Golodenko NN (2014) CFD simulation of ECAE through a multiple-angle die with a movable inlet wall. Chem Eng Commun 201(9):1221–1239. doi:10.1080/00986445.2014.894509

Perig AV, Golodenko NN (2014) CFD 2D simulation of viscous flow during ECAE through a rectangular die with parallel slants. Int J Adv Manuf Technol 74(5–8):943–962. doi:10.1007/s00170-014-5827-2

Pisarenko GS, Yakovlev AP, Matveev VV (1973) Guide to strength of materials. Naukova Dumka, p. 704 (in Russian)

Potapkin VF, Levkin AN, Satonin AV, Romanov SM, Vorob’yev YA, Gribkov EP (2000) Stress state and kinematics for rolling of powered materials on metal substrate. Powder Metall Met C+ 39(1–2):11–17. doi:10.1007/BF02677434

Ramakrishnan M, Muthupandi V (2013) Application of submerged arc welding technology with cold wire addition for drum shell long seam butt welds of pressure vessel components. Int J Adv Manuf Technol 65(5–8):945–956. doi:10.1007/s00170-012-4230-0

Satonin ОV, Gribkov EP, Ivanov ОО, Kosyakov ОV (2011) Installation for experimental definition of the basic indicators of physicomechanical properties powder materials of various structure. Patent № 59317 Ukraine. IPC (2006.01) В 22 F 3/03, Donbass State Engineering Academy, № u201012688 (in Ukrainian)

Simon O, Guigon P (2003) Correlation between powder-packing properties and roll press compact heterogeneity. Powder Technol 130:257–264. doi:10.1016/S0032-5910(02)00202-4

Stepanenko AV, Isaevich LA, Kharlan VE (1990) Geometric and power parameters of the metal powder rolling process. I. Boundaries of the seat of deformation and stress field in the lag and forward slip zones. Powder Metall Met Ceram 29(2):101–105. doi:10.1007/BF00794530

Stepanenko AV, Isaevich LA, Kharlan VE (1991) Geometric and energy-force parameters of the process of rolling of metal powders II. The rolling power, moment, and contact stresses and distribution of density in the area of deformation. Powder Metall Met Ceram 30(2):101–105. doi:10.1007/BF00797280

Tseng H-C, Hung C, Huang C-C (2010) An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment. Int J Adv Manuf Technol 48(9–12):1029–1036. doi:10.1007/s00170-009-2446-4

Vinogradov GA, Katashinskij VP (1979) Theory sheet rolling metal powders and granules. Metallurgy, p. 224 (in Russian)

Volkogon GM, Dmitriev AM, Dobryakov EP (1991) Advanced technological processes stamping parts from powders and equipment. Mechanical Engineering, p. 320 (in Russian)

Wang PT, Karabin ME (1994) Evolution of porosity during thin plate rolling of powder-based porous aluminum. Powder Technol 78(1):67–76. doi:10.1016/0032-5910(93)02768-6

Wang X, Hua L, Han X, Wang X, Wang D, Liu Y (2014) Numerical simulation and experimental study on geometry variations and process control method of vertical hot ring rolling. Int J Adv Manuf Technol 73(1–4):389–398. doi:10.1007/s00170-014-5770-2

Yeremeev VB (1985) Mechanized welding of worn parts fitting thermal power. Surfacing. Experience and efficacy. Paton Electric Welding Institute of NAS of Ukraine, Kiev, pp 41–44, in Russian

Zheng Z-X, Xia W, Zhou ZY (2013) Experimental and numerical modeling for powder rolling. Rev Adv Mater Sci 33:330–336, http://www.ipme.ru/e-journals/RAMS/no_43313/05_433_zheng.pdf

Zhudra AP (2009) New equipment for welding cones and bowls charging devices. Autom Weld 9:57–59 (in Russian)

Zhudra AP (2010) Durable powder surfacing ribbons. Welder 6:6–10 (in Russian)

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendices

1.1 Appendix 1. Derivation of the plasticity condition and dependence of deformations upon the relative powder density for the case of rolling with plain rolls

The plasticity condition for porous materials is used for the derivation of the values of the axial and contact stresses in the case of the state of plane deformation and has the following form [34]:

where σ 1; σ 2; σ 3 are the principal stresses, which act at the deformable powder core; α; β are the coefficients, which take into account the specific character of deformation for powder composite; σ s is the yield limit of the base of powder material.

We will derive the formula for the value of the principal stress σ 2. For this purpose, we will use the governing equations of the flow theory for porous materials, i.e., we will introduce the dependencies between the principal stresses σ 1; σ 2; σ 3 and the principal rates \( \overset{\bullet }{\varepsilon_1} \); \( \overset{\bullet }{\varepsilon_2} \); \( \overset{\bullet }{\varepsilon_3} \) of the plastic deformation [34]:

where \( \dot{\lambda} \) is Lagrange multiplier.

The dependence of the rate of the volume plastic deformation from the stresses is defined in [34] through the following algebraic expression:

After substitution of expressions (22–24) into formula (25), and assuming that within the consolidation zone is the state of plane deformation with \( \overset{\bullet }{\varepsilon_2}=0 \), we have the following formula:

For further derivation, we will transform the following expression:

After factoring out the principal stresses, we will have:

So

In the case of the state of plane deformation, the following expressions will take place:

So Eq. (29) after substitution of (30) yields:

After substitution of formulae (30–31) into the plasticity condition (21), we will have:

After transformations of (32), we will have:

After further mathematical simplifications, the plasticity condition will be as follows:

It is possible to estimate the values of the coefficients α and β in accordance with [34] as

where γ x is the current value of the relative density of the powder phase:

where ρ x ; ρ 0 are the values of the density of the powder composition and its solid phase, respectively;a; m; n are constant coefficients, which are determined for every specific composition of the powder medium and characterize the dependence of the coefficients α and β on the relative density γ x .

The value of the normal axial stresses is determined in [30] from the plasticity condition (34):

In accordance with [34], it is possible to transform the formulae (22)–(24) taking into account the equality of the ratios of the principal strains and the principal strain rates:

By the assumed plane deformation state within the consolidation zone, we have ε 1 = ε h ; ε 2 = 0; ε 3 = ε x ; σ 3 = σ x ; σ 1 = р x . The averaged principal stress σ 2 for the plane deformation state is defined according to (31).

In view of the above, the ratio of the principal deformations is defined as

In the final form, we have:

The final expression is derived by means of the parameters of stress–strain state of selected elementary volume:

It is necessary to note that the law of volume conservation is not valid for powder material rolling due to their compactibility. So further transformations require introduction of the law of mass conservation [20]. As a result, the expression for relative density may be written as:

The computation of equivalent deformation ε e is performed simultaneously with the computation of the principal deformations ε hx and ε 1x [34]:

where k is the quantity of partitions of the deformation zone.

1.2 Appendix 2. Determination of stresses in the deformation zone during rolling of powder tape

The condition of static equilibrium of the final volume under the influence of stress-induced force, acting on a selected elementary volume of the powder core has the following form:

After transformations of (44), we will have:

The positive value of normal stresses σ xi in the equilibrium equations corresponds to compressive stresses. The directions of tangential stresses within the zone of slippage on the delivery side and the zone of slippage on the entry side have been taken into account by means of the sign of the friction coefficients.

The plasticity condition (37) for powder materials is the second equation for determination of values of axial and contact stresses in the case of the state of plane deformation. The substitution of (37) into equilibrium Eq. (45) yields:

In (46), indices 1 and 2 mean that associated parameters are referred to the initial and final cross-sections of the volume, respectively.

After further transformations, we will transform (46) into the following expression:

Then we square right-hand and left-hand sides of (47):

For simplification of notations, we will make a change of variables and introduce the following auxiliary variables:

Taking into account the additional formulae (49)–(52) the Eq. (48) takes the following form:

The Eq. (53) is the quadratic equation with respect to the variable p xi2. The solution of this quadratic equation allows us to derive in final form the unknown value of the contact stresses:

Taking into account the determined value p xi2 and addressing again the plasticity condition for porous materials (37), we will determine the value of the normal axial stresses σ xi2:

as well as the values of tangential stresses τ y хi2 and τ s хi2 :

The derived values σ xi2, p xi2, τ y xi2 and τ s xi2 comprehensively describe the stressed state in the deformation zone and allow us to calculate the relative density of the powder layer γ xi2 because the value of γ xi2 is necessary for the correct accounting of the real distribution character for coefficients α and β along the length of the deformation zone.

1.3 Appendix 3. Basic code for numerical solution of the problem

Determination of the length of deformation zone with taking into account the process asymmetry

500:

kv2 = (R2 + Hp) / R1 * kv

Rpr = 2 * R1 * (R2 + Hp) / (R1 + R2 + Hp)

Lmax = Sqr(2 * R1 * (Hp0 − hl1))

Lmin = Sqr(Rpr * (Hp0 − hl1))

Procedure call for determination of stressed-strained state

Call calc(L0, kv2, Rpr)

Determination of shell deformation

kv = 1

1000:

i = Kr

1001:

Wx1 = 4 − 5 * (L0 − Xm(i − 1)) / (L0 − Xm(i)) + ((L0 − Xm(i − 1)) ^ 5 / (L0 − Xm(i)) ^ 5)

MI = (B2 * H1 ^ 3 − b * (H1 − Hp) ^ 3) / 12

Wx2 = Px2m(i) * b * (L0 − Xm(i)) ^ 5 / 120 / ep / MI

Wx = Abs(Wx1 * Wx2)

Wxm(i) = Wx

Y2 = Sqr((R2 + Hp) ^ 2 − Xm(i) ^ 2) − Sqr((R2 + Hp) ^ 2 − Xm(i − 1) ^ 2)

arcs = Xm(i) / (R2 + Hp): arcs1 = arcs ^ 2 / (1 − arcs ^ 2)

Y1 = (Xm(i − 1) − Xm(i)) * (Tan(Atn(Sqr(arcs1)))) + Wx

Y1m(i) = Y1: Y2m(i) = Y2

If Y2 > Y1 Then

xotr = Xm(i): Potr = Px2m(i)

Else

i = i − 1

If i = 1 Then

arcs2 = L0 / R1: arcs3 = arcs2 ^ 2 / (1 − arcs2 ^ 2)

arcs4 = L0 / (R2 + Hp): arcs5 = arcs4 ^ 2 / (1 − arcs4 ^ 2)

H0r = hl1 + R1 * (1 − Cos(Atn(Sqr(arcs3)))) + (R2 + Hp) * (1 − Cos(Atn(Sqr(arcs5))))

GoTo 3000

End If

GoTo 1001

End If

dH01 = R1 * (1 − Cos(Atn(Sqr(arcs3))))

WH0 = Potr * b * (L0 − xotr) ^ 5 * 4 / (120 * ep * MI)

arcs6 = xotr / (R2 + Hp): arcs7 = arcs6 ^ 2 / (1 − arcs6 ^ 2)

dH02 = (R2 + Hp) * (1 − Cos(Atn(Sqr(arcs7)))) + (L0 − xotr) * Tan(Atn(Sqr(arcs7))) + WH0

Ldyg = Sqr(R2 ^ 2 - (R2 − dH02) ^ 2)

Ldygm(i) = Ldyg

H0r = hl1 + dH01 + dH02

Determination of the length of deformation zone with taking into account the shell bending process

3000:

dLL = 2 * (Lmax − Lmin) / (Lmax + Lmin) * 100

If dLL <5 Then GoTo 2000

If H0r > Hp0 Then Lmax = L0

If H0r < Hp0 Then Lmin = L0

Procedure call for determination of stressed–strained state

Call calc(L0, kv2, Rpr)

Determination of integral characteristics of the process

2000:

L0 = Ldyg

Procedure call for determination of stressed–strained state

Call calc(L0, kv2, Rpr)

rpl = Yxm(Kr)

Rolling force

i = 1: SP = 0

1150: SP = SP + Px2m(i)

i = i + 1

If i < = Kr Then GoTo 1150

Rpr = L0 ^ 2 / (Hp0 − hl1)

PSR = SP / Kr

i = 1

SP = Px2m(1) * dx / 2: SM1 = Px2m(1) * Fx1m(1) * dx * R1 / 2: SM2 = Px2m(1) * Fx2m(1) * dx * R2 / 2

If i <1.5 Then GoTo 1310

1280: SP = SP +0.5 * (Px2m(i) + Px2m(i − 1)) * dx

SM1 = SM1 + 0.5 * (Px2m(i) + Fx1m(i) + Px2m(i − 1) * Fx1m(i − 1)) * dx * R1

SM2 = SM2 + 0.5 * (Px2m(i) + Fx2m(i) + Px2m(i − 1) * Fx2m(i − 1)) * dx * R2

1310: i = i + 1

If i < = Kr Then GoTo 1280

PPL = SP * b / 1000: MPL1 = SM1 * b / 1000: MPL2 = SM2 * b / 1000

PYP = Px2m(Kr) * LYP * b / 2000

PPR = PPL + PYP

Rolling moment (rolling torque)

MM1 = MPL1 − 0.5 * Px2m(Kr) * LYP * fop1 * R1 / 1000

MM2 = MPL2 − 0.5 * Px2m(Kr) * LYP * fop2 * R2 / 1000

Strip tension (bend tension)

T0 = G0 * Hp0 * b

T1 = Gx2 * hl1 * b

Rolling power

Sop1 = (Hn1 / hl1 − 1) * 100

Sop2 = (Hn2 / hl1 − 1) * 100

N1 = (MM1 / R1) * V1 * hl1 / Hn1

N2 = (MM2 / R2) * V1 * hl1 / Hn2

Ns = N1 + N2

Specific power consumption of the process

rpl = rpl * rpm

AYD = (MM1 * hl1 / R2 / Hn1 + MM2 * hl1 / R1 / Hn2) / (b * hl1 * rpl)

End Sub

Procedure for computation of stressed–strained state

Sub calc(L0, kv2, Rpr)

510:

Pmax = −1E + 35

EE = 0

Determination of the length of deformation zone with taking into account the influence of shell on deformation zone geometry

Lop1 = L0 * Sqr(hl1 * (kv2 − 1) / (Hp0 − hl1) + kv2 * (Lop1 / L0) ^ 2)

Lot1 = L0 − Lop1

Lop2 = 0.00001

Lot2 = L0

Determination of the initial parameters for computation

dx = L0 / Kr

DH = Hp0 − hl1

Hn1 = hl1 + DH * (Lop1 / L0) ^ ah

Hn2 = hl1 + DH * (Lop2 / L0) ^ ah

X1 = L0: Gx1 = 0: Hx1 = Hp0

i = 1

yx1 = Rpu / rpm

Al = a * (1 − yx1) ^ m

If Al >0.5 Then Al = 0.5

BT = yx1 ^ (2 * n)

GTF = a0 * a1 ^ a2

Px1 = GTF * Sqr(4 * (1 + Al) * BT / 3 / (1 + 4 * Al))

Fx11 = fot1: Fx21 = fot2

Iteration procedure

710:

The section coordinate determination

X2 = X1 − dx

Determination of the current thickness of the powder layer

Hx2 = hl1 + DH * (X2 / L0) ^ ah

Reduction determination

DHx = Hx1 − Hx2

Friction coefficients determination

If X2 > Lop1 Then Fx12 = fot1 * ((X2 − Lop1) / (L0 − Lop1)) ^ af1

If X2 > Lop2 Then Fx22 = fot2 * ((X2 − Lop2) / (L0 − Lop2)) ^ af2

If X2 < = Lop1 Then Fx12 = −fop1 * ((Lop1 − X2) / Lop1) ^ af1

If X2 < = Lop2 Then Fx22 = −fop2 * ((Lop2 − X2) / Lop2) ^ af2

Determination of normal contact stresses

xx1 = (1–2 * Al) * Hx2 / (1 + 4 * Al) +1 / 2 * (Hx1 − Hx2 − (Fx12 + Fx22) * dx)

xx2 = Px1 / 2 * (Hx1 - Hx2 - (Fx11 + Fx21) * dx) - Gx1 * Hx1

xx3 = Hx2 ^ 2 * (((1–2 * Al) / (1 + 4 * Al)) ^ 2–1)

GTF = a0 * (EE + a1) ^ a2

xx4 = Hx2 ^ 2 * 4 * (1 + Al) * BT * GTF ^ 2 / 3 / (1 + 4 * Al)

BBC = xx1 ^ 2 * xx2 ^ 2 − (xx1 ^ 2 − xx3) * (xx2 ^ 2 − xx4)

BBCm(i) = BBC

Px2 = (−xx1 * xx2 + Sqr(BBC)) / (xx1 ^ 2 − xx3)

Determination of normal stresses

ABC = Px2 ^ 2 * (((1–2 * Al) / (1 + 4 * Al)) ^ 2–1) + 4 * (1 + Al) * BT * GTF ^ 2 / 3 / (1 + 4 * Al)

ABCm(i) = ABC

Gx2 = (1–2 * Al) * Px2 / (1 + 4 * Al) − Sqr(ABC)

If Px2 > Pmax Then Pmax = Px2: imax = i

Determination of tangential contact stresses

tau1vm(i) = Px1 * Fx11

tau1nm(i) = Px1 * Fx21

tau2vm(i) = Px2 * Fx12

tau2nm(i) = Px2 * Fx22

Determination of deformation characteristics

Eh = (Hx1 − Hx2) / Hx1

DeHx = (Px2 * (1 + 4 * Al) − Gx2 * (1–2 * Al)) / (Gx2 * (1 + 4 * Al) − Px2 * (1–2 * Al))

DeHx = Abs(DeHx)

Ex = Eh / DeHx

Determination of relative density of powder

yx1 = yx1 * Hx1 / Hx2 / (1 + Ex)

Yxm(i) = yx1

Al = a * (1 − yx1) ^ m

BT = yx1 ^ (2 * n)

Equivalent deformation determination

dE = BT ^ (1 / 2) * (2 / 9 * ((Ex − Eh) ^ 2 + Eh ^ 2 + Ex ^ 2)) / yx1

EE = EE + dE

Formulation of transition condition to the next cross-section

Alm(i) = Al: BTm(i) = BT: GTFm(i) = GTF

Gxm(i) = Gx2: Xm(i) = X2

X1 = X2: Px1 = Px2: Gx1 = Gx2: Fx11 = Fx12: Fx21 = Fx22

Hx1 = Hx2

Xm(i) = X2: Hxm(i) = Hx2: Fx1m(i) = Fx12: Fx2m(i) = Fx22

Px2m(i) = Px2

i = i + 1

The transition to computation of the next cross-section

If i < = Kr Then GoTo 710

The final relative density of powder

YHL1 = hl1 * Px2 / el

The length of elastic recovery zone

LYP = Sqr(Rpr * YHL1)

The value of normal stresses at output of the deformation zone

Gx2 = Gx2 − 0.5 * LYP * Px2 * (fop1 + fop2) / hl1

The condition of validity of equality of normal stresses at output of the deformation zone and forward pull stress

If Gx2 > G0 Then kv2 = kv2 + 0.001: GoTo 510

End Sub

Rights and permissions

About this article

Cite this article

Gribkov, E.P., Perig, A.V. & Danilyuk, V.A. Research into the process of producing powder tapes. Int J Adv Manuf Technol 77, 1087–1104 (2015). https://doi.org/10.1007/s00170-014-6496-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6496-x