Abstract

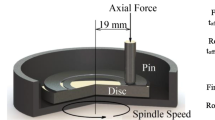

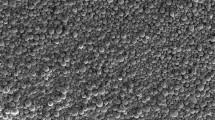

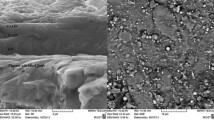

Manufacturing technology must ensure the production of parts with required characteristics: dimensional accuracy, overall strength, and surface quality. The surface layers in metal forming generally remain at the surface. The quality of the deformed surface is therefore determined by the initial surface and the history of the various forming processes undergone. Surface roughness influences surface quality and wear of metal forming products. Pin-on-disc tests at a range of temperatures were employed to study the influence of die coatings on the surface quality of a two-phase brass alloy during forging operation. The pins were made in H13 hot work tool steel and given duplex surface treatments including plasma nitriding and physical vapor deposition (PVD) coatings. The discs were machined from CuZn38Pb2 forging brass. Mechanical properties, surface roughness, and compositional properties of pins were determined by nanoindentaion, two-dimensional profilometer, and scanning electron microscopy equipped with energy-dispersive X-ray detector, respectively. At 25 °C, wear track parameters were more affected by the changes in Young’s modulus and the surface roughness of the pins. At 250 °C, the highest tendency to adhesion was observed in H13 steel pin. At 700 °C, oxidation of the pins influenced the wear track parameters on the discs. R a parameters inside the wear tracks were constant at 25 and 250 °C, but R ku parameters were maximum for the wear tracks of disc in contact with plasma nitriding and H13 pins at 25 and 250 °C, respectively. At 700 °C, the lowest surface quality was for the disc in contact with H13 steel pin. It was concluded that in forging process of brass alloys, the surface quality and deformation behavior of workpiece were improved by applied PVD coating on the surface of the die.

Similar content being viewed by others

References

Elleuch K, Elleuch R, Mnif R, Fridrici V, Kapsa P (2006) Sliding wear transition for the CW614 brass alloy. Tribol Int 39((4):290–296. doi:10.1016/ j.triboint.2005.01.036

Panagopoulos CN, Georgiou EP, Simeonidis K (2012) Lubricated wear behavior of leaded α+β brass. Tribol Int 50(0):1–5. doi:10.1016/j.triboint.2011.12.016

Ben Jemaa MC, Mnif R, Elleuch R (2013) Tribological behavior of CW614 brass coated with Ni-Cr layers sliding against 52100 steel. J Materi Eng Perform 22(6):1729–1734. doi:10.1007/s11665-012-0437-3

Kchaou M, Alimi A, Elleuch R, Desplanques Y (2013) Characterisation of oxidation and wear oxidised surfaces of H13 steel/brass in dry sliding conditions. Int J Microstruct Mater Prop 8(4):373–384. doi:10.1504/IJMMP.2013.057073

Saiz E, Cannon RM, Tomsia AP (2008) High-temperature wetting and the work of adhesion in metal/oxide systems. Annu Rev Mater Res 38:197–226. doi:10.1146/ annurev.matsci. 38.060407.132443

Bay N, Azushima A, Groche P, Ishibashi I, Merklein M, Morishita M, Nakamura T, Schmid S, Yoshida M (2010) Environmentally benign tribo-systems for metal forming. CIRP Ann Manuf Technol 59(2):760–780. doi:10.1016/j.cirp.2010.05.007

Matsumoto R, Osakada K (2002) Lubrication and friction of magnesium alloys in warm forging. CIRP Ann Manuf Technol 51(1):223–226. doi:10.1016/ S0007-8506(07)61504-2

Matsumoto R, Kawashima H, Osakada K (2007) Friction and adhesion in dry warm forging of magnesium alloy with coated tools. J Solid Mech Mater Eng 1:397–405

Li J, Yang G, Zhang W, Tu S, Chen X (2008) Thermal effect on piezoelectric stick–slip actuator systems. Rev Sci Instrum 79(4):046108. doi:10.1063/1.2908162

Berger M, Hogmark S (2002) Tribological properties of selected PVD coatings when slid against ductile materials. Wear 252(7–8):557–565. doi:10.1016/S0043-1648(02)00011-X

Davis JR, Committee ASMIH (2001) Copper and Copper Alloys. ASM International

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(06):1564–1583

Zheng S, Sun Y, Bloyce A, Bell T (1995) Characterization of plasma nitrided and PVD-TiN duplex treated Armco iron and En40B steel by nanoindentation. Mater Manuf Process 10(4):815–824. doi:10.1080/10426919508935068

Kuiying C, Zhao LR, John R, John ST (2003) Alloying effects on elastic properties of TiN-based nitrides. J Phys D Appl Phys 36(21):2725

Bobzin K, Bagcivan N, Ewering M, Brugnara R (2012) Vanadium alloyed PVD CrAlN coatings for friction reduction in metal forming applications. Tribol Ind 34(2):101–107

Kchaou M, Elleuch R, Desplanques Y, Boidin X, Degallaix G (2010) Failure mechanisms of H13 die on relation to the forging process—a case study of brass gas valves. Eng Fail Anal 17(2):403–415. doi:10.1016/j.engfailanal.2009.08.015

Hertz H (1881) The contact of solid elastic bodies. J Pure Appl Math 92:156–171

Johnson KL, Johnson KL (1987) Contact Mechanics. Cambridge University Press

Yeo HT, Choi Y, Hur KD (2001) Analysis and design of the prestressed cold extrusion die. Int J Adv Manuf Technol 18(1):54–61. doi:10.1007/s001700170094

Batista JCA, Godoy C, Buono VTL, Matthews A (2002) Characterisation of duplex and non-duplex (Ti, Al)N and Cr–N PVD coatings. Mater Sci Eng A 336(1–2):39–51. doi:10.1016/S0921-5093(01)01953-0

Mahboubi F, Abdolvahabi K (2006) The effect of temperature on plasma nitriding behaviour of DIN 1.6959 low alloy steel. Vacuum 81(3):239–243. doi:10.1016/ j.vacuum.2006.03.010

Sanchette F, Ducros C, Schmitt T, Steyer P, Billard A (2011) Nanostructured hard coatings deposited by cathodic arc deposition: from concepts to applications. Surf Coat Technol 205(23–24):5444–5453. doi:10.1016/j.surfcoat.2011.06.015

Ducros C, Cayron C, Sanchette F (2006) Multilayered and nanolayered hard nitride thin films deposited by cathodic arc evaporation. Part 1: Deposition, morphology and microstructure. Surf Coat Technol 201(1–2):136–142. doi:10.1016/ j.surfcoat.2005.11.102

Ducros C, Cayron C, Sanchette F (2006) Multilayered and nanolayered hard nitride thin films deposited by cathodic arc evaporation. Part 1: Deposition, morphology and microstructure. Surf Coat Technol 201(1–2):136–142. doi:10.1016/ j.surfcoat.2005.11.102

Dobrzański LA, Lukaszkowicz K, Křiž A (2003) J Mater Process Technol 143–144:832–837. doi:10.1016/S0924-0136(03)00351-0

Ma S, Li Y, Xu K (2001) The composite of nitrided steel of H13 and TiN coatings by plasma duplex treatment and the effect of pre-nitriding. Surf Coat Technol 137(2–3):116–121. doi:10.1016/S0257-8972(00)01073-2

Tillmann W, Vogli E, Momeni S (2010) Improvement of press dies used for the production of diamond composites by means of DUPLEX-PVD-coatings. Surf Coat Technol 205(5):1571–1577. doi:10.1016/j.surfcoat.2010.08.048

Polcar T, Cavaleiro A (2011) High-temperature tribological properties of CrAlN, CrAlSiN and AlCrSiN coatings. Surf Coat Technol 206(6):1244–1251. doi:10.1016/j.surfcoat.2011.08.037

Rodríguez-Baracaldo R, Benito JA, Puchi-Cabrera ES, Staia MH (2007) High temperature wear resistance of (TiAl)N PVD coating on untreated and gas nitrided AISI H13 steel with different heat treatments. Wear 262(3–4):380–389. doi:10.1016/ j.wear.2006.06.010

Birol Y, İsler D, Urgen M (2011) High-Temperature sliding wear testing of cathodic arc physical vapor deposition AlTiN- and AlTiON-coated hot work tool steels. Metall Mater Trans A 42(11):3316–3322. doi:10.1007/s11661-010-0474-1

Lange K (2001) Metal forming: surface quality of products. In: Buschow KHJ, Cahn RW, Flemings MC (eds) Encyclopedia of materials: science and technology (second edition). Elsevier, Oxford, pp 5433–5436. doi:10.1016/B0-08-043152-6/00947-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebrahimzadeh, I., Ashrafizadeh, F. A comparative study of surface deformation and quality of brass workpiece in contact with coated dies by pin-on-disc testing. Int J Adv Manuf Technol 77, 609–620 (2015). https://doi.org/10.1007/s00170-014-6473-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6473-4