Abstract

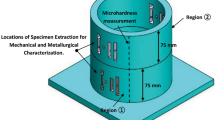

Improvement of die life under hot forging of brass alloys is considered vital from both economical and technical points of view. One of the best methods for improving die life is duplex coatings. In this research, the influence of temperature on the tribological behavior of duplex-coated die steel rubbing against forging brass was investigated. The wear tests were performed on a pin-on-disk machine from room temperature to 700 °C; the pins were made in H13 hot work tool steel treated by plasma nitriding and by PVD coatings of TiN-TiAlN-CrAlN. The disks were machined from a two-phase brass alloy too. The results revealed that the friction coefficient of this tribosystem went through a maximum at 550 °C and decreased largely at 700 °C. Furthermore, the formation of Cr2O3 caused the reduction of friction coefficient at 700 °C. PVD coatings proved their wear resistance up to 550 °C, well above the working temperature of the brass forging dies.

Similar content being viewed by others

References

M. Kchaou, R. Elleuch, Y. Desplanques, X. Boidin, and G. Degallaix, Failure Mechanisms of H13 Die on Relation to the Forging Process—A Case Study of Brass Gas Valves, Eng. Fail. Anal., 2010, 17(2), p 403–415

M. Kchaou, R. Elleuch, Y. Desplanques, X. Boidin, and G. Degallaix: ‘Étude du comportement de l’acier X40crMov5-1 pré-oxydé en frottement-usure sous faible vitesse de glissement’, Annales de chimie, 2010, Lavoisier, p 41-57

M. Kchaou, A. Alimi, R. Elleuch, and Y. Desplanques, Characterisation of Oxidation and Wear Oxidised Surfaces of H13 Steel/Brass in Dry Sliding Conditions, Int. J. Microstruct. Mater. Prop., 2013, 8(4), p 373–384

T. Altan, Cold and Hot Forging: Fundamentals and Applications, ASM International, Materials Park, 2005

T. Sato, T. Besshi, D. Sato, and K. Inouchi, Evaluation of Wear and Tribological Properties of Coatings Rubbing Against Copper, Wear, 1998, 220(2), p 154–160

M. Pellizzari, A. Molinari, and G. Straffelini, Damage Mechanisms in Duplex Treated Hot Work Tool Steel Under Thermal Cycling, Surf. Eng., 2002, 18(4), p 289–298

P. Panjan, B. Navinšek, M. Čekada, and A. Zalar, Oxidation Behaviour of TiAlN Coatings Sputtered at Low Temperature, Vacuum, 1999, 53(1–2), p 127–131

C.W. Kim and K.H. Kim, Anti-oxidation Properties of TiAlN Film Prepared by Plasma-Assisted Chemical Vapor Deposition and Roles of Al, Thin Solid Films, 1997, 307(1–2), p 113–119

M. Kawate, A. Kimura Hashimoto, and T. Suzuki, Oxidation resistance of Cr1-XAlXN and Ti1-XAlXN films, Surf. Coat. Technol., 2003, 165(2), p 163–167

T. Polcar and A. Cavaleiro, High Temperature Properties of CrAlN, CrAlSiN and AlCrSiN Coatings—Structure and Oxidation, Mater. Chem. Phys., 2011, 129(1–2), p 195–201

K.S. Klimek, A. Gebauer-Teichmann, P. Kaestner, and K.T. Rie, Duplex-PACVD Coating of Surfaces for Die Casting Tools, Surf. Coat. Technol., 2007, 201, p 5628–5632

J.C.A. Batista, C. Godoy, V.T.L. Buono, and A. Matthews, Characterisation of Duplex and Non-Duplex (Ti, Al)N and Cr-N PVD Coatings, Mater. Sci. Eng. A, 2002, 336(1–2), p 39–51

I. Ebrahimzadeh and F. Ashrafizadeh, High Temperature Wear and Frictional Properties of Duplex-Treated Tool Steel Sliding Against a Two Phase Brass, Ceram. Int., 2014, 40, p 16429–16439

J.R. Davis and A.S.M.I.H. Committee, Copper and Copper Alloys, ASM International, 2001

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(06), p 1564–1583

K. Bobzin, N. Bagcivan, M. Ewering, and R. Brugnara, Vanadium Alloyed PVD CrAlN Coatings for Friction Reduction in Metal Forming Applications, Tribol. Ind., 2012, 34(2), p 101–107

E. Lugscheider, K. Bobzin, and K. Lackner, Investigations of Mechanical and Tribological Properties of CrAlN + C Thin Coatings Deposited on Cutting Tools, Surf. Coat. Technol., 2003, 174, p 681–686

F. Mahboubi and K. Abdolvahabi, The Effect of Temperature on Plasma Nitriding Behaviour of DIN 1.6959 Low Alloy Steel, Vacuum, 2006, 81(3), p 239–243

P.H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens, Microstructural Design of Hard Coatings, Prog. Mater. Sci., 2006, 51(8), p 1032–1114

P.J. Blau, On the nature of running-in, Tribol. Int., 2006, 38(11), p 1007–1012

L. Menezes, P. Kishore, and S.V. Kailas, Influence of Surface Texture and Roughness Parameters on Friction and Transfer Layer Formation During Sliding of Aluminium Pin on Steel Plate, Wear, 2009, 267(9–10), p 1534–1549

N.W. Khun, H. Zhang, J.L. Yang, and E. Liu, Tribological Performance of Silicone Composite Coatings Filled with Wax-Containing Microcapsules, Wear, 2012, 296(1–2), p 575–582

O. Barrau, C. Boher, C. Vergne, F. Rezai-Aria, and R. Gras, Investigations of Friction and Wear Mechanisms of Hot Forging Tool Steels, Karlstad Univ., 2002, 1, p 81–94

Acknowledgments

Special thanks to Sevin Plasma Surface Engineering Co. for supplying the PVD coatings and Tribology laboratory of Malek Ashtar University for carrying out the pin-on-disk tests. The authors wish to thank Azaran Industrial Group for providing materials and machining the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebrahimzadeh, I., Ashrafizadeh, F. The Influence of Temperature on the Frictional Behavior of Duplex-Coated Die Steel Rubbing Against Forging Brass. J. of Materi Eng and Perform 24, 529–535 (2015). https://doi.org/10.1007/s11665-014-1301-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1301-4