Abstract

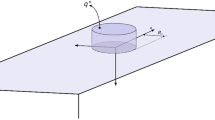

The effect of activated tungsten inert gas welding process parameters on the weld bead geometry of duplex stainless steel alloy 2205 is analyzed and discussed in this research paper. The welding design matrix for conducting the experiments is made using the central composite design of response surface methodology (RSM). The input process parameters (current, torch speed, and arc gap) are varied at five levels which results in 21 experimental trials. Bead-on-plate welds are made on 10-mm-thick duplex stainless steel plates. The responses (depth of penetration, area of depth of penetration, bead width, bead height, heat-affected zone width, and aspect ratio) are measured after conducting the experiments. A second-order response surface model is developed for predicting the responses for the set of given input parameters. Then, multi-objective optimization is performed to obtain the desired weld bead geometry using desirability approach.

Similar content being viewed by others

References

Tsann-Shyi C, Kuang-Hung T, Hsien-Lung T (2011) Study of the characteristics of duplex stainless steel activated tungsten inert gas welds. Mater Des 32(1):255–263

Miura M, Koso M, Kudo T, Tsuge H (1990) The effect of nickel and nitrogen on the microstructure and corrosion resistance of duplex stainless steel weldment. Weld Int 4(3):200–206

Cortie MB, Potgieter JH (1991) The effect of temperature and nitrogen content on the partitioning of alloy elements in duplex stainless steels. Metall Transn A 22(10):2173–2179

Karlsson L, Tolling J (2006) Experiences and new possibilities in welding duplex stainless steels. Proc., IIW Regional Congress on Welding and Related Inspection Technologies, South Africa

Cam G (2011) Friction stir welded structural materials: beyond Al-alloys. Int Mater Rev 56(1):1–48

Juang SC, Tarng YS (2002) Process parameter selection for optimizing the weld pool geometry in the tungsten inert gas welding of stainless steel. J Mater Process Technol 122(1):33–37

Chandrasekhar N, Vasudevan M (2010) The intelligent modelling for optimization of A-TIG welding process. Mater Manuf Process 25(11):1341–1350

Vasantharaja P, Maduraimuthu V, Vasudevan M, Palanichamy P (2012) Assessment of residual stresses and distortion in stainless steel weld joints. Mater Manuf Process 27(12):1376–1381

Huang HY, Shyu SW, Tseng KH, Chou CP (2005) Evaluation of TIG flux welding on the characteristics of stainless steel. Sci Technol Weld Join 10(5):566–573

Leconte S, Paillard P, Chapelle P, Henrion G, Saindrenan J (2006) Effect of oxide fluxes on activation mechanisms of the tungsten inert gas process. Sci Technol Wel Join 11(4):389–397

Benyounis KY, Olabi AG, Hashmi MSJ (2008) Multi response optimization of CO2 laser welding process of austenitic stainless steel. Opt Laser Technol 40:76–87

Ruggiero A, Tricarico L, Olabi AG, Benyounis KY (2011) Weld-bead profile and costs optimization of the CO2 dissimilar laser-welding process of low carbon steel and austenitic steel AISI316. Opt Laser Technol 43:82–90

Kim D, Rhee S, Park H (2002) Modelling and optimization of a GMA welding process by genetic algorithm and response surface methodology. Int J Prod Res 40(7):1699–1711

Balasubramanian KR, Sankaranarayanasamy K, Suthakar T, Sivapirakasam SP, Buvanashekaran G (2010) Mathematical modelling and optimization of laser welding of butt joints. Int J Compu Mate Sci Surf Engg 3(4):321–335

Dinesh Babu P, Buvanashekaran G, Balasubramanian KR (2012) Experimental investigation of laser transformation hardening of low alloy steel using response surface methodology. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4616-z

Huang H-Y (2010) Effect of activated flux on the welded joint characteristics in gas metal arc welding. Mate Des 31(5):2488–2495

Shyu SW, Huang HY, Tseng KH, Chou CP (2008) Study of the performance of stainless steel A-TIG welds. J Mate Engg Perform 17(2):193–201

Xu YL, Dong ZB, Wei YH, Yang CL (2007) Marangoni convection and weld shape variation in A-TIG welding process. Theore Appl Fract Mech 48(2):178–186

Lowke JJ, Tanaka M, Ushio M (2005) Mechanisms giving increased weld depth due to a flux. J Phys D: Appl Phys 38(18):3438–3445

Tseng K-H, Hsu C-Y (2011) Performance of activated TIG process in austenitic stainless steel welds. J Mater Process Technol 211(3):503–512

Montgomery DC (2001) Design and analysis of experiments, 5th edn. Wiley, New York

Ibrahim HM, Elkhidir EE (2011) Response surface method as an efficient tool for media optimization. Tren Appl Sci Res 6(2):121–129

Kazakov YV, Koryagin KB (2002) The efficiency of activating fluxes in manual argon-arc welding. Weld Int 6(11):886–889

Heiple CR, Roper JR (1982) Mechanism for minor effect on GTA fusion zone geometry. Weld J 61(4):97–102

Wang Y, Shi Q, Tsai HL (2001) Modelling of the effects of surface active elements on flow patterns and weld penetration. Metall Mater Transa B 32(1):145–161

Marya M, Edwards GR (2002) Chloride contributions in flux assisted GTA welding of magnesium alloys. Weld J 81(11):291–298

Lu SP, Fujii H, Nogi K (2004) Marangoni convection and weld shape variation in Ar-O2 shielded GTA welding. Mater Sci Engg A 380:290–297

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qua Technol 12(4):214–219

Benyounis KY, Olabi AG (2008) Optimization of different welding processes using statistical and numerical approaches—a reference guide. Adv Engg Soft 39(6):483–496

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Korra, N.N., Vasudevan, M. & Balasubramanian, K.R. Multi-objective optimization of activated tungsten inert gas welding of duplex stainless steel using response surface methodology. Int J Adv Manuf Technol 77, 67–81 (2015). https://doi.org/10.1007/s00170-014-6426-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6426-y