Abstract

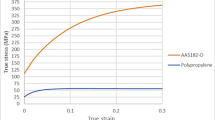

Metal/polymer/metal laminated sheets have shown promising properties, as being light weight, in automotive and aircraft industries. In this paper, the effect of punch radius on springback in the early stage of V-die bending process of aluminum/polypropylene/aluminum sheets is studied both numerically and experimentally. To analyze springback behavior, contact pressure evolution during bending process was studied using numerical simulation. Springback behavior relies on bending moment and sheet thinning. Bending moment and sheet thinning depend on circumferential and transverse stress distributions along sheet thickness and sheet length. Overall opposite effect of bending moment and sheet thinning makes an increase in springback with punch radius. Parametric study was performed to investigate the effect of polymeric core on springback. It was observed that in a given thickness configuration, springback of laminate lies between those of polymeric and metallic monolayer sheets with the same thickness. Also, an increase in sandwich sheet thickness leads to a decrease in springback.

Similar content being viewed by others

References

Pickin CG, Young K, Tuersley I (2007) Joining of lightweight sandwich sheets to aluminium using self-pierce riveting. Mater Des 28:2361–2365

Welch TE, Schwaegler JR (1999) Cost and performance benefits for laminated steel body. SAE Tech Pap 1999-01-1784

Vinson JR (1999) The behavior of sandwich structures of isotropic and composite materials. Technomic Publishing Company, Inc., Pennsylvania

Rao MD (2003) Recent applications of viscoelastic damping for noise control in automobiles and commercial airplanes. Sound Vib 262:457–474

Hylite presentation and Hylite applications http://www.jtmconsultancy.nl. Accessed 1 June 2011

Link TM (2001) Formability and performance of steel-plastic-steel laminated sheet materials. SAE Tech Pap 2001-01-0079.

Kim KJ, Rhee MH, Choi B-I, Kim C-W, Sung C-W, Han C-P, Kang K-W, Won S-T (2009) Development of application technique of Aluminum sandwich sheet for automotive hood. Int J Precis Eng Manuf 10–4:71–75

Parsa MH, Ettehad M, Nasher Al Ahkami S (2009) FLD determination of Al3105/polypropylene/Al 3105 sandwich sheet using numerical calculation and experimental investigations. Int J Mater Form 2–1:407–410

Kim KJ, Kim D, Choi SH, Chung K, Shin KS, Barlat F, Oh KH, Youn JR (2003) Formability of AA5182/polypropylene/AA5182 sandwich sheets. J Mater Process Technol 139:1–7

Weiss M, Dingle ME, Rolfe BF, Hodgson PD (2007) The influence of temperature on the forming behavior of metal/polymer laminates in sheet metal forming. Trans ASME 129:530–537

Kim KJ (2005) Plastic strain ratios and planar anisotropy of AA5182/polypropylene/AA5182 sandwich sheet. Int J Automot technol 3–3:259–268

Kim JK, Thomson PF (1990) Forming behaviour of sheet steel laminate. J Mater Process Technol 22:45–64

Kim JK, Thomson PF (1990) Separation behaviour of sheet steel laminate during forming. J Mater Process Technol 22:147–161

Parsa MH, Ettehad M (2008) Prediction of delamination during deep-drawing of steel–polymer–steel sandwich sheet material. In: Yang DY (ed) Proceeding of the 9th International Conference on Technology of Plasticity, Korea p 980–985

Wang Y, Chen J, Li HB (2008) Improved cohesive zone model and its application in interface contact analysis. Acta Metall Sin (Engl Lett) 21–4:295–302

Katsuhiko I, Masayuki K, Susumu F (1981) Bending and springback theory of metal-polymer sandwich laminates. J Macromol Sci B 19–4:773–791

Yuen WYD (1996) A generalised solution for the prediction of springback in laminated strip. J Mater Process Technol 61:254–264

Mohammadi SV, Parsa MH, Jalali Aghchai A (2011) Effect of the thickness distribution and setting condition on springback in multi-layer sheet bending. Int J Eng Sci Technol 3–4:225–235

Li H, Chena J, Yang J (2012) Experimental and numerical investigation of laminated steel sheet in V-bending process considering nonlinear visco-elasticity of polymer layer. J Mater Process Technol 212:36–45

Parsa MH, Nasher al ahkami S, Ettehad M (2010) Experimental and finite element study on the spring back of double curved aluminum/polypropylene/aluminum sandwich sheet. Mater Des 31:4174–4183

Fedin YA, Kharichkin ES (1974) Determining the spring-back angle and accuracy of parts made in bending dies. Chemical and Petroleum Engineering, 10(3):246--248

Osman MA, Shazly M, El-Mokaddem A, Wifi AS (2010) Springback prediction in V-die bending: modeling and experimentation. J Achiev Mater Manuf Eng 38–2:179–186

Bakhshi-Jooybari M, Rahmani B, Daeezadeh V, Gorji A (2009) The study of spring-back of CK67 steel sheet in V-die and U-die bending processes. Mater Des 30:2410–2419

Leu D-K, Hsieh C-M (2007) The influence of coining force on spring-back reduction in V-die bending process. J Mater Process Technol 196:230–235

Thipprakmas S (2013) Finite element analysis of sided coined-bead technique in precision V-bending process. Int J Adv Manuf Technol 65:679–688

Wagoner R (2004) Sheet springback. In: Raabe D, Roters F, Barlat F, Chen LQ (eds) Continuum scale simulation of engineering materials: fundamentals– microstructures–process applications. Wiley-VCH Verlag GmbH & Co. KGaA, Germany, pp 777–794

Papeleux L, Ponthot J-P (2002) Finite element simulation of springback in sheet metal forming. J Mater Process Technol 125–126:785–791

Xu WL, Ma CH, Li CH, Feng WJ (2004) Sensitive factors in springback simulation for sheet metal forming. J Mater Process Technol 151:217–222

Wagoner RH, Li M (2007) Simulation of springback: through-thickness integration. Int J Plast 23:345–360

Wagoner RH, Li M (2005) Advances in springback, In: Smith LM, Pourboghrat F, Yoon J.-W Stoughton TB (eds) Numisheet 2005:209–214.

Geng L, Wagoner RH (2002) Role of plastic anisotropy and its evolution on springback. Int J Mech Sci 44:123–148

Schönbach E, Glanzer G, Kubli W, Selig M. Simulation of secondary operations and springback—the implicit shell provides a precise and rapid solution. In: Dorel B. (ed) Advanced methods in material forming. Berlin Heidelberg: Springer pp 349–360

Jung DW (2002) Static-explicit finite element method and its application to drawbead process with springback. J Mater Process Technol 128:292–391

Kutt LM, Pifko AB, Nardiello JA, Papazian JM (1998) Slow-dynamic finite element simulation of manufacturing processes. Comput Struct 66–1:1–17

Finn MJ, Galbraith PC, Wu L, Hallquist JO, Lum L, Lin T-L (1995) Use of a coupled explicit-implicit solver for calculating spring-back in automotive body panels. J Mater Process Technol 50:395–409

Burchitz IA, Meinders T, Hu´etink J (2006) Influence of numerical parameters on springback prediction in sheet metal forming. In: Dorel B (ed) The 9th International Conference on Material Forming, ESAFORM pp 407–410

Lee SW, Yang DY (1998) An assessment of numerical parameters influencing springback in explicit finite element analysis of sheet metal forming process. J Mater Process Technol 80–81:60–67

Prior AM (1994) Applications of implicit and explicit finite element techniques to metal forming. J Mater Process Technol 45:649–656

Narasimhan N, Lovell M (1999) Predicting springback in sheet metal forming: an explicit to implicit sequential solution procedure. Finite Elem Anal Des 33:29–42

Kumar A,Viswanath P, Mahesh K, Swati M, Vinay Kumar PM, Abhijit A, Singh S. K. (2010) Prediction of springback in V-bending and design of dies using finite element simulation. Int. J. Mater Product Technol 39-3/4: 291–301

Tekaslan O, Gerger N, Seker U (2008) Determination of spring-back of stainless steel sheet metal in “V” bending dies. Mater Des 29:1043–1050

Panthi SK, Ramakrishnan N, Pathak KK, Chouhan JS (2007) An analysis of springback in sheet metal bending using finite element method (FEM). J Mater Process Technol 186:120–124

Ramezani M, Ripin ZM, Ahmad R (2010) Modelling of kinetic friction in V-bending of ultra-high-strength steel sheets. Int J Adv Manuf Technol 46:101–110

Huang Y-M, Chen T-C (2004) An influence of tool profiles on the v-bending process of sheet metal. Key Eng Mater 274–276:553–558

Huang Y-M, Leu D-K (1999) Effects of process variables on v-die bending process of steel sheet. Int J Mech Sci 40–7:631–650

Huang Y-M, Lu Y-H (1992) Elasto-plastic finite-element analysis of V-shape sheet bending. J Mater Process Technol 35:129–150

Huang Y-M, Leu D-K (1995) Finite element analysis of contact problems for a sheet metal bending process. Comput Struct 57:15–21

Hung Y-M (2007) Finite element analysis on the V-die coining bend process of steel metal. Int J Adv Manuf Technol 34:287–294

Huang Y-M, Chen T-C (2003) An elasto-plastic finite-element analysis of sheet metal camber process. J Mater Process Technol 140:432–440

Forcellese A, Fratini L, Gabrielli F, Micari F (1998) The evaluation of springback in 3D stamping and coining processes. J Mater Process Technol 80–81:108–112

de Magalhaes Correi JP, Aloch S, Ahzi S, Husson C (2004) Experimental and numerical study of springback in V-die bending of copper sheets. In: Ghosh SJ, Castro JC, Lee JK (eds) Proceeding of material processing and design: modelling, simulation and applications NUMIFORM pp 901–909

Forcellese A, Fratinibl L, Gabrielli F, Micari F (1996) Computer aided engineering of the sheet bending process. J Mater Process Technol 60:225–232

Xu HJ, Liu YQ, Zhong W (2012) Three-dimensional finite element simulation of medium thick plate metal forming and springback. Finite Elem Anal Des 51:49–58

Thipprakmas S, Phanitwong W (2011) Process parameter design of spring-back and spring-go in V-bending process using Taguchi technique. Mater Des 32:4430–4436

Thipprakmas S, Rojananan S (2008) Investigation of spring-go phenomenon using finite element method. Mater Des 29:1526–1532

Ramezani M, Ripin ZM (2009) Effect of friction models on stress distribution of sheet materials during V-bending process. World Acad Sci Eng Technol 56:654–659

Matuszak A (2000) Factors influencing friction in steel sheet forming. J Mater Process Technol 106:250–253

Leu D-K (2013) Effect of roughness geometry on friction during micro V-die bending by using finite element method. Int J Adv Manuf Technol 68:227–240

Huang Y-M (2007) Finite element analysis on the V-die coining bend process of steel metal. Int J Adv Manuf Technol 34:287–294

Wagoner RH, Lim H, Lee MG (2013) Advanced issues in springback. Int J Plast 45:3–20

Duc-Toan N, Seung-Han Y, Dong-Won J, Tien-Long B, Young-Suk K (2012) A study on material modeling to predict spring-back in V-bending of AZ31 magnesium alloy sheet at various temperatures”. Int J Adv Manuf Technol 62:551–562

Leu D-K (2013) Position deviation in V-die bending process with asymmetric bend length. Int J Adv Manuf Technol 64:93–103

Burchitz IA (2008) Improvement of springback prediction in sheet metal forming. Dissertation, University of Twente

Abaqus 6.9: user’s examples and theory manuals. Dassault systèmes; 2009.

Prasad YKDV, Somasundaram S (1993) A mathematical model for bend-allowance calculation in automated sheet-metal bending. J Mater Process Technol 39:337–356

Wang C, Kinzel G, Altan T (1993) Mathematical modeling of plane-strain bending of sheet and plate. J Mater Process Technol 39:279–304

Marciniak Z, Duncan J (1992) Mechanics of sheet metal forming. Great Britain: Edward Arnold, Chap. 6, pp 82–106.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Parsa, M.H., Mohammadi, S.V. & Aghchai, A.J. Al3105/polypropylene/Al3105 laminates springback in V-die bending. Int J Adv Manuf Technol 75, 849–860 (2014). https://doi.org/10.1007/s00170-014-6173-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6173-0