Abstract

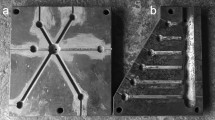

In this study, effects of gating system type on hot tearing occurrence of Al–4 wt% Cu castings were investigated using the instrumented constrained T-shaped casting method. Three different gating systems, i.e. a conventional pressurized gating system, a conventional unpressurized gating system and a naturally pressurized gating system with surge control arrangement, were used for this purpose. The presence of oxide bifilms in torn surfaces were studied using scanning electron microscopy and energy-dispersive x-ray spectroscopy. It was shown that hot tearing severity could be predicted from the final slope of the load–time curves. Hot tearing susceptibility was highest for the conventional pressurized gating system. This was associated with the high surface turbulence of the melt during mould filling which would result in the formation of such defects as oxide bifilms. For the naturally pressurized gating system, the maximum load tolerable by the solidifying casting was much larger than those for conventional gating systems and severity of hot tears formed were much less significant. Hot tearing occurrence in all the castings was closely associated with the presence of thick oxide layers. In other words, greater amounts of oxide bifilms were observed on the hot tearing surfaces of the more severely torn castings.

Similar content being viewed by others

References

Campbell J (2011) Complete casting handbook: metal casting processes, techniques and design. Butterworth-Heinemann, Oxford, pp 470–476 and 489–493

Lin S (1999) A study of hot tearing in wrought aluminum alloys. Ph.D. thesis, Universite of Quebec

Lin S, Aliravci C, Pekguleryuz MO (2007) Hot-tear susceptibility of aluminum wrought alloys and the effect of grain refining. Metall Mater Trans A 38:1056–1068

Hatami N, Babaei R, Dadashzadeh M, Davami P (2008) Modeling of hot tearing formation during solidification. J Mater Process Tech 205:506–513

Kamga HK, Larouche D, Bournane M, Rahem A (2010) Hot tearing of aluminum–copper B206 alloys with iron and silicon additions. Mat Sci Eng A 527:7413–7423

Zhou L, Huang YD, Mao PL, Kainer KU, Liu Z, Hort N (2011) Influence of composition on hot tearing in binary Mg–Zn alloys. Int J Cast Metal Res 24:170–176

Choi H, Cho WH, Konishi H, Kou S, Li X (2012) Nanoparticle-induced superior hot tearing resistance of A206 alloy. Metall Mater Trans A. doi:10.1007/s11661-012-1531-8

Monroe C, Beckermann C (2006) Simulation of hot tearing and distortion during casting of steel: comparison with experiments. Proc 60th Technical and Operating Conf, Chicago, SFSA

Cao G, Kou S (2007) Real-time monitoring of hot tearing in AZ91E magnesium casting. Proc 111th Metal Casting Congress, Texas, paper 07–034

Easton M, Wang H, Grandfield J, Davidson CJ, StJohn D, Sweet LD, Couper MJ (2012) Observation and prediction of the hot tear susceptibility of ternary Al-Si-Mg alloys. Metall Mater Trans A 43:3227–3238

Davidson C, Viano D, Lu L, StJohn D (2006) Observation of crack initiation during hot tearing. Int J Cast Metal Res 19:59–65

Karunakar DB, Rai RN, Patra S, Datta GL (2009) Effects of grain refinement and residual elements on hot tearing in aluminum castings. Int J Adv Manuf Tech 45:851–858

Zhen ZS, Hort N, Huang YD, Utke O, Petri N, Kainer KU (2009) Hot tearing behaviour of binary Mg-1Al alloy using a contraction force measuring method. Int J Cast Metal Res 22:331–334

Nabawy AM, Samuel AM, Samuel FH, Doty HW (2012) Influence of additions of Zr, Ti-B, Sr, and Si as well as of mold temperature on the hot-tearing susceptibility of an experimental Al-2 % Cu-1 % Si alloy. J Mater Sci 47:4146–4158

Nasr Esfahani MR, Niroumand B (2010) Study of hot tearing of A206 aluminum alloy using instrumented constrained T-shaped casting method. Mater Charact 61:318–324

Campbell J (2009) The bifilm concept: prospects of defect-free castings. Proc Int Aluminum Conf, Tehran, pp 1–9

Campbell J (2011) Complete casting handbook: metal casting processes, techniques and design. Butterworth-Heinemann, Oxford, pp 528–535

Campbell J (2006) An overview of the effects of bifilms on the structure and properties of cast alloys. Metall Mater Trans B 37:857–863

Raiszadeh R, Griffiths WD (2006) A method to study the history of a double oxide film defect in liquid aluminum alloys. Metall Mater Trans B 37:865–871

Staley JT, Tiryakioglu M, Campbell J (2007) The effect of increased HIP temperatures on bifilms and tensile properties of A206-T71 aluminum castings. Mat Sci Eng A 460:324–334

Griffiths WD, Lai NW (2007) Double oxide film defects in cast magnesium alloy. Metall Mater Trans A 38:190–196

Campbell J (2011) Complete casting handbook: metal casting processes, techniques and design. Butterworth-Heinemann, Oxford, pp 787, 857–862 and 897–898

Campbell J (2004) Castings practice. Butterworth-Heinemann, Oxford

Li S, Apelian D, Sadayappan K (2012) Hot tearing in cast Al alloys: mechanisms and process controls. Int J Metal Casting 7:51–57

Campbell J (2011) Complete casting handbook: metal casting processes, techniques and design. Butterworth-Heinemann, Oxford, pp 77–88 and 692–694

Bagherpoor-Torghabe H (2011) M.Sc. thesis, Isfahan University of Technology

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bagherpoor-Torghabe, H., Niroumand, B. & Karbasi, M. On the effect of gating system type on occurrence of hot tears in Al–4 wt% Cu castings. Int J Adv Manuf Technol 75, 677–685 (2014). https://doi.org/10.1007/s00170-014-6172-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6172-1