Abstract

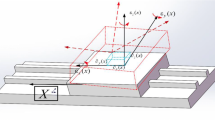

Geometric errors directly affect the tool tip position, reduce machining accuracy, and are one of the most important errors of multi-axis machining tool. However, the geometric errors are intercoupling, and the measured values at different points vary and are stochastic. The identification of the most crucial geometric errors and the determination of a method to control them is a key problem to improve the machining accuracy of machine tool. To achieve this goal, a new analytical method, to identify crucial geometric errors for a multi-axis machine tool is proposed here based on multibody system (MBS) theory and global sensitivity analysis. The volumetric error modeling of multi-axis machine tool has been given by MBS theory, which describes the topological structure of multibody system simply and conveniently in a matrix. The stochastic characteristic of geometric errors is taken into consideration and Sobol global sensitivity analysis method is introduced to identify crucial geometric errors of machine tool. A vertical machining center is selected as an illustration example. The analysis results reveal that the analytical method presented in this paper can identify the crucial geometric errors and are helpful to improve the machining accuracy of multi-axis machine tool.

Similar content being viewed by others

References

Sartori S, Zhang GX (1995) Geometric error measurement and compensation of machines. CIRP Ann Manuf Technol 44(2):599–609

Ahn KG, Cho DW (2000) Analysis of the volumetric error uncertainty of a three-axis machine tool by beta distribution. Int J Mach Tools Manuf 40(15):2235–2248

Cheng Q, Wu C, Gu PH, Chang WF, Xuan DS (2013) An analysis methodology for stochastic characteristic of volumetric error in multi-axis CNC machine tool. Math Probl Eng 2013, 863283. doi:10.1155/2013/863283

Wu CW, Tang CH, Chang CF, Shiao YS (2012) Thermal error compensation method for machine center. Int J Adv Manuf Technol 59:681–689

Hsu YY, Wang SS (2007) A new compensation method for geometry errors of five-axis machine tools. Int J Mach Tools Manuf 47(2):352–360

Khan AW, Chen WY (2011) A methodology for systematic geometric error compensation in five-axis machine tools. Int J Adv Manuf Technol 53(5):615–628

Ni J (1997) CNC machine accuracy enhancement through real-time error compensation. J Manuf Sci Eng 119(4):717–725

Okafor AC, Ertekin YM (2000) Derivation of machine tool error models and error compensation procedure for three axes vertical machining center using rigid body kinematics. Int J Mach Tools Manuf 40:1199–1213

Zhu SW, Ding GF, Qin SF, Jiang L, Li Z, Yan KY (2012) Integrated geometric error modeling, identification and compensation of CNC machine tools. Int J Mach Tools Manuf 52(1):24–29

Tarantola S, Saltelli A (2003) SAMO 2001: methodological advances and innovative applications of sensitivity analysis. Reliab Eng Syst Saf 79(2):121–122

Nojedeh MV, Habibiand M, Arezoo B (2011) Tool path accuracy enhancement through geometrical error compensation. Int J Mach Tools Manuf 51(6):471–482

Rao N, Bedi S, Buchal R (1996) Implementation of the principal-axis method for machining of complex surfaces. Int J Adv Manuf Technol 11(4):249–257

Rahman M, Heikkala J, Lappalainen K (2000) Modeling measurement and error compensation of multi-axis machine tools. Int J Mach Tools Manuf 40(10):1535–1546

Eman K (1987) A generalized geometric error model for multi-axis machines. CIRP Ann Manuf Technol 36(1):253–256

Xie J, Zhou RM, Xu J, Zhong YG (2010) Form-truing error compensation of diamond grinding wheel in CNC envelope grinding of free-form surface. Int J Adv Manuf Technol 48(9):905–912

Lin Y, Shen Y (2003) Modeling of five-axis machine tool metrology models using the matrix summation approach. Int J Adv Manuf Technol 21(4):243–248

Jha BK, Kumar A (2003) Analysis of geometric errors associated with five-axis machining centre in improving the quality of Cam profile. Int J Mach Tools Manuf 43(6):629–636

Kong LB, Cheung CF, To S, Lee WB, Du JJ, Zhang ZJ (2008) A kinematics and experimental analysis of form error compensation in ultra-precision machining. Int J Mach Tools Manuf 48(12):1408–1419

Chen JX, Lin SW, He BW (2014) Geometric error compensation for multi-axis CNC machines based on differential transformation. Int J Adv Manuf Technol 71(1–4):635–642

Xu C, Gertner G (2007) Extending a global sensitivity analysis technique to models with correlated parameters. Comput Stat Data Anal 51(12):5579–5590

Karkee M, Steward BL (2010) Local and global sensitivity analysis of a tractor and single axle grain cart dynamic system model. Biosyst Eng 106(4):352–366

Chhatre S, Francis R, Zhou YH, Titchener-Hooker N, King J, Keshavarz-Moore E (2008) Global sensitivity analysis for the determination of parameter importance in bio-manufacturing processes. Biotechnol Appl Biochem 51(2):79–90

Cossarini G, Solidoro C (2008) Global sensitivity analysis of a trophodynamic model of the Gulf of Trieste. Ecol Model 212(1):16–27

Wang KH, Ke JB, Lee WC (2007) Reliability and sensitivity analysis of a repairable system with warm standbys and R unreliable service stations. Int J Adv Manuf Technol 31(11):1223–1232

Sudret B (2008) Global sensitivity analysis using polynomial chaos expansions. Reliab Eng Syst Saf 93(7):964–979

Tsutsumi M, Saito A (2004) Identification of angular and positional deviations inherent to 5-axis machining centers with a tilting-rotary table by simultaneous four-axis control movements. Int J Mach Tools Manuf 44(12):1333–1342

Hong C, Ibaraki S, Matsubara A (2011) Influence of position dependent geometric errors of rotary axes on a machining test of cone frustum by five-axis machine tools. Precis Eng 35(1):1–11

Lee RS, Lin YH (2012) Applying bidirectional kinematics to assembly error analysis for five-axis machine tools with general orthogonal configuration. Int J Adv Manuf Technol 62(9–12):1261–1272

Chen GD, Liang YC, Sun YZ, Chen WQ, Wang B (2013) Volumetric error modeling and sensitivity analysis for designing a five-axis ultra-precision machine tool. Int J Adv Manuf Technol 68(9–12):2525–2534

Deng C, Xie SQ, Wu J, Shao XY (2014) Position error compensation of semi-closed loop servo system using support vector regression and fuzzy PID control. Int J Adv Manuf Technol 71(5–8):887–898

Saltelli A, Ratto M, Tarantola S, Campolongo F, Commission E, Ispra JRC (2006) Sensitivity analysis practices: strategies for model-based inference. Reliab Eng Syst Saf 91(10–11):1109–1125

Abdessalem AB, El-Hami A (2014) Global sensitivity analysis and multi-objective optimization of loading path in tube hydroforming process based on meta modelling techniques. Int J Adv Manuf Technol 71(5–8):753–773

Lagerwall G, Kiker G, Munoz-Carpena R, Wang NM (2014) Global uncertainty and sensitivity analysis of a spatially distributed ecological model. Ecol Model 275:22–30

Miro S, Hartmann D, Schanz T (2014) Global sensitivity analysis for subsoil parameter estimation in mechanized tunneling. Comput Geotech 56:80–88

Kim K, Kim MK (1991) Volumetric accuracy analysis based generalized geometric error model in multi-axes machine tools. Mech Mach Theory 26(2):207–212

Soons JA, Theuws FC, Schellenkens PH (1992) Modeling the errors of multi-axis machines: a general methodology. Precis Eng 14(1):5–19

Fu GQ, Fu JZ, Xu YT, Chen ZC (2014) Product of exponential model for geometric error integration of multi-axis machine tools. Int J Adv Manuf Technol 71(9–12):1653–1667

Rahman M, Heikkala J, Lappalainen K (2000) Modeling, measurement and error compensation of multi-axis machine tools. Part I: theory. Int J Mach Tools Manuf 40(10):1535–1546

Shin YH (1991) Characterization of CNC machining centers. J Manuf Syst 10(5):407–421

Lee DK, Zhu ZK, Lee KI, Yang SH (2011) Identification and measurement of geometric errors for a five-axis machine tool with a tilting head using a double ball-bar. Int J Precis Eng Manuf 12(2):337–343

Sobol IM (2001) Global sensitivity indices for nonlinear mathematical models and their Monte Carlo estimates. Math Comput Simul 55(1–3):271–280

Homma T, Saltelli A (1996) Importance measures in global sensitivity analysis of nonlinear models. Reliab Eng Syst Saf 52(1):1–17

Slamani M, Mayer R, Balazinski M, Zargarbashi SHH, Engin S, Lartigue C (2010) Dynamic and geometric error assessment of an XYC axis subset on five-axis high-speed machine tools using programmed end point constraint measurements. Int J Adv Manuf Technol 50(9–12):1063–1073

Zhang HT, Yang JG, Zhang Y, Shen JH, Wang C (2011) Measurement and compensation for volumetric positioning errors of CNC machine tools considering thermal effect. Int J Adv Manuf Technol 55(1):275–283

Helton JC, Davis FJ (2003) Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems. Reliab Eng Syst Saf 81(1):23–69

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, Q., Zhao, H., Zhang, G. et al. An analytical approach for crucial geometric errors identification of multi-axis machine tool based on global sensitivity analysis. Int J Adv Manuf Technol 75, 107–121 (2014). https://doi.org/10.1007/s00170-014-6133-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6133-8