Abstract

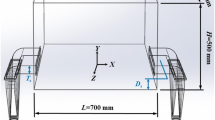

Slurry plays an important role in the material removal of chemical mechanical polishing (CMP). However, the behavior of abrasive particles of the slurry in the interface between the wafer and the pad during CMP is not fully understood. In this paper, a new computational fluid dynamic (CFD) model was developed. It was a combination of multiphase and discrete phase modeling. The abrasive particles behavior and the slurry distribution in the interface were simulated using this model. The total numbers of particles in the gap were quantified to characterize their mechanical effects under different operating parameters. The simulation results showed that when the gap thickness increased and speeds of the wafer and the pad decreased, the total number of particles in the gap increased. It also found that the particles were non-uniformly distributed below the wafer. The results have the capacity of providing a deeper insight understanding of the material removal of the CMP mechanism.

Similar content being viewed by others

References

Zhong ZW (2008) Recent advances in polishing of advanced materials. Materials and Manufacturing Processes 23(5):449–456

Thakurta DG, Borst CL, Schwendeman DW, Gutmann RJ, Gill WN (2001) Three-dimensional chemical mechanical planarization slurry flow model based on lubrication theory. Journal of the Electrochemical Society 148(4):207–214. doi:10.1149/1.1355691

Terrell EJ, Higgs CF (2006) Hydrodynamics of slurry flow in chemical mechanical polishing a review. Journal of the Electrochemical Society 153(6):15–22

Levert JA, Korach CS (2009) CMP friction as a function of slurry silica nanoparticle concentration and diameter. Tribology Transactions 52(2):256–261. doi:10.1080/10402000802593130

Remsen EE, Anjur S, Boldridge D, Kamiti M, Li S, Johns T, Dowell C, Kasthurirangan J, Feeney P (2006) Analysis of large particle count in fumed silica slurries and its correlation with scratch defects generated by CMP. Journal of the Electrochemical Society 153(5):G453–G461

Terrell EJ, Higgs Iii CF (2007) A modeling approach for predicting the abrasive particle motion during chemical mechanical polishing. Journal of Tribology 129(4):933–941

Basim GB, Adler JJ, Mahajan U, Singh RK, Moudgil BM, Zantye PB (2000) Effect of particle size of chemical mechanical polishing slurries for enhanced polishing with minimal defects. Journal of The Electrochemical Society 147(9):3523–3528

Tamboli D, Banerjee G, Waddell M (2004) Novel interpretations of CMP removal rate dependencies on slurry particle size and concentration. Electrochemical and Solid-State Letters 7(10):F62–F65. doi:10.1149/1.1795033

Miyoshi A, Nakagawa H, Matsukawa K (2005) Simulation on chemical mechanical polishing using atomic force microscope. Microsystem Technologies-Micro-and Nanosystems-Information Storage and Processing Systems 11(8–10):1102–1106. doi:10.1007/s00542-005-0509-5

Bastaninejad M, Ahmadi G (2005) Modeling the effects of abrasive size distribution, adhesion, and surface plastic deformation on chemical-mechanical polishing. Journal of the Electrochemical Society 152(9):G720–G730

Luo J, Dornfeld D (2003) Material removal regions in chemical mechanical planarization for submicron integrated circuit fabrication: coupling effects of slurry chemicals, abrasive size distribution, and wafer-pad contact area. IEEE Transactions on Semiconductor Manufacturing 16(1):45–56

Chagarov E, Adams JB (2003) Molecular dynamics simulations of mechanical deformation of amorphous silicon dioxide during chemical-mechanical polishing. Journal of Applied Physics 94(6):3853–3861

Han X (2007) Study micromechanism of surface planarization in the polishing technology using numerical simulation method. Applied Surface Science 253(14):6211–6216

Jianbin L (2007) Variation of surface layer during chemical mechanical polish. Indian Journal of Pure and Applied Physics 45(4):403–405

Han X, Gan YX (2012) Analysis the microscopic solid-based wear process in the chemical mechanical planarization. Surface and Interface Analysis 44(5):590–600

Chen KS, Yeh HM, Yan JL, Chen YT (2009) Finite-element analysis on wafer-level CMP contact stress: reinvestigated issues and the effects of selected process parameters. International Journal of Advanced Manufacturing Technology 42(11–12):1118–1130. doi:10.1007/s00170-008-1672-5

Chiu J-T, Lin Y-Y (2008) Modal analysis of multi-layer structure for chemical mechanical polishing process. International Journal of Advanced Manufacturing Technology 37(1/2):83–91. doi:10.1007/s00170-007-0960-9

Lin Y-Y, Lo S-P (2003) A study on the stress and nonuniformity of the wafer surface for the chemical-mechanical polishing process. The International Journal of Advanced Manufacturing Technology 22(5–6):401–409. doi:10.1007/s00170-003-1544-y

Lo SP, Lin YY, Huang JC (2007) Analysis of retaining ring using finite element simulation in chemical mechanical polishing process. International Journal of Advanced Manufacturing Technology 34(5–6):547–555. doi:10.1007/s00170-006-0622-3

Rogers C, Coppeta J, Racz L, Philipossian A, Kaufman FB, Bramono D (1998) Analysis of flow between a wafer and pad during CMP processes. Journal of Electronic Materials 27(10):1082–1087. doi:10.1007/s11664-998-0141-0

Haosheng C, Jiang L, Darong C, Jiadao W (2006) Nano particle’s behavior in non-Newtonian slurry in mechanical process of CMP. Tribology Letters 24(3):179–186

Sung I-H, Kim HJ, Yeo CD (2012) First observation on the feasibility of scratch formation by pad–particle mixture in CMP process. Applied Surface Science 258(20):8298–8306. doi:10.1016/j.apsusc.2012.05.044

Tian Y, Lai S, Zhong ZW (2012) Slurry flow visualisation of chemical mechanical polishing based on a computational fluid dynamics model. Advanced Materials Research 565:324–329

Shi F, Zhao B (1998) Modeling of chemical-mechanical polishing with soft pads. Applied Physics A: Materials Science & Processing 67(2):249–252

FLUENT A (2009) 12.0 Theory guide. Ansys Inc

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nguyen, N.Y., Tian, Y. & Zhong, Z.W. Modeling and simulation for the distribution of slurry particles in chemical mechanical polishing. Int J Adv Manuf Technol 75, 97–106 (2014). https://doi.org/10.1007/s00170-014-6132-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6132-9