Abstract

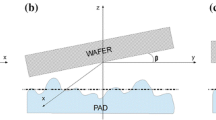

In this study, a three-dimensional finite element model was established to perform modal analysis of the chemical mechanical polishing process. The contact boundary conditions were considered in the wafer and pad, and the influence of the static load exerted on the carrier was considered in order to investigate dynamic behaviour of the wafer. The analysis was in two steps. Firstly, a given pressure was exerted on the carrier and the geometric nonlinear effect and large deformation theory were used to carry out static analysis. Secondly, the results of the analysis were used to perform modal analysis of the wafer. The results gave way to four conclusions. (1) Due to the offset configuration of the wafer and pad, the von Mises stress distribution was asymmetric. Therefore, the stress on the wafer appeared to be almost uniform near its centre, goes through a maximum near the edge, and decreased as the edge is approached. This tendency is similar to that of the removal rate profile experiment, which proved that the proposed finite element model for CMP is acceptable. (2) Due to the extremely thin thickness of the film, wafer and pad, most mode shapes are predominant in out-plane deformation. Furthermore, since the y-axis is symmetric in the three-dimensional model, there were double roots in some modes. (3) When the load was larger, the tangent stiffness and the natural frequency would also be reduced. The pressure changes did not have much affect on mode shape. (4) Since the soft materials of the pad and film have significantly different Young’s modulus’ than hard materials, the natural frequencies of harder materials for the pad and film increase.

Similar content being viewed by others

References

Runnels SR, Renteln P (1993) Modeling the effect of polish pad deformation on wafer surface stress distributions during chemical-mechanical polishing. In: Herndon, TO (ed) Proceedings of the symposia on interconnects, contact metallization, and multilevel metallization and reliability for semiconductor devices, interconnects, and thin insulator materials, Electrochemical Society, New Jersey, USA, pp 110–121

Runnels SR, Eyman LM (1994) Tribology analysis of chemical-mechanical polishing. J Electrochem Soc 141(6):1698–1701

Kaanta CW, Landis HS (1991) Radial uniformity control of semiconductor wafer polishing. US Patent 5,036,630, 6 August 1991

Warnock J (1991) A two-dimensional process model for CMP planarization. J Electrochem Soc 138(8):2398–2402

Sivaram S, Tolles R, Bath H, Lee E, Leggett R (1992) Chemical mechanical polishing of inter-level dielectrics: models for removal rate and planarity. Technical Report, SEMATECH, Austin, Texas

Wang D, Lee J, Holland K, Bibby T, Beaudoin S, Cale T (1997) von Mises stress in chemical-mechanical polishing processes. J Electrochem Soc 144(3):1122–1127

Srinivasa-Murthy C, Wang D, Beaudoin SP, Bibby T, Holland K, Cale TS (1997) Stress distribution in chemical-mechanical polishing. Thin Solid Films 308:533–537

Baker AR (1997) The origin of the edge effects in CMP. J Electrochem Soc 96(22):228–237

Lou JF, Dornfeld DA (2001) Material removal mechanism in chemical-mechanical polishing: theory and modeling. IEEE Trans Semicond Manuf 14(2):112–132

Lou JF, Dornfeld DA, Mao Z, Hwang E (2001) Integrated model for chemical-mechanical polishing based on a comprehensive material removal model. In: Proceedings of the sixth international conference on chemical-mechanical polish (CMP) planarization (CMP-MIC), Santa Clara, CA, USA, pp 1–8

Lou JF, Dornfeld DA (2003) Material removal regions in chemical mechanical planarization for submicron integrated circuit fabrication: coupling effects of slurry chemicals, abrasive size distribution and wafer-pad contact area. IEEE Trans Semicond Manuf 16(1):45–56

Preston F (1927) Optimization of computer controlled polishing. Glass Technol 11:214–219

MARC (2001) Volume A: theory and user information, version 2001. MARC Analysis Research Corporation, Palo Alto, CA, USA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chiu, JT., Lin, YY. Modal analysis of multi-layer structure for chemical mechanical polishing process. Int J Adv Manuf Technol 37, 83–91 (2008). https://doi.org/10.1007/s00170-007-0960-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0960-9