Abstract

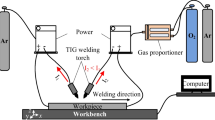

This study presents a new double-gas tungsten arc welding heat source, with two arcs serially arranged on the same side of a workpiece. During welding, a tungsten tube and inert gas are additionally used to help the rear electric arcs burn at the bottom of the existing weld pool formed by the fore arc. Bead-on-plate welding experiments using this heat source are carried out to investigate the heating efficiency of the heat source and the influences of the arc current, the gas flow rate in the tube on the welding process. Results show that the heat source presents higher melting efficiency and stronger heat penetrability compared with normal double-gas tungsten arc welding. The interactions of the forces near the weld pool in the welding process are also analyzed. Observation of the arc behavior by a high-speed camera proves that the electromagnetic force between the two burning arcs stabilizes the burning arcs and thus the welding process.

Similar content being viewed by others

References

Lidam RN, Manurung YHP, Haruman E, Haruman E, Redza MR, Rahim MR, Sulaiman MS, Zakaria MY, Tham G, Abas SK, Chau CY (2013) Angular distortion analysis of the multipass welding process on combined joint types using thermo-elastic-plastic FEM with experimental validation. Int J Adv Manuf Technol 69:2373–2386

Liu LM, Zhuang ZL, Liu F, Zhu ML (2013) Additive manufacturing of steel-bronze bimetal by shaped metal deposition: interface characteristics and tensile properties. Int J Adv Manuf Technol 69:2131–2137

Ding XP, Li H, Yang LJ, Gao Y (2013) Numerical simulation of metal transfer process in tandem GMAW. Int J Adv Manuf Technol 69:107–112

Ramakrishnan M, Padmanaban MV (2013) Studies on fracture toughness of cold wire addition in narrow groove submerged arc welding process. Int J Adv Manuf Technol 68:293–316

Marya M, Edwards GR, Liu S (2004) An investigation on the effects of gases in GTA welding of a wrought AZ80 magnesium alloy. Weld J 83:203–212

Min D, Shen J, Lai SQ, Chen J (2009) Effect of heat input on the microstructure and mechanical properties of tungsten inert gas arc butt-welded AZ61 magnesium alloy plates. Mater Character 60:1583–1590

Qi BJ, Yang MX, Cong BQ, Liu FJ (2013) The effect of arc behavior on weld geometry by high-frequency pulse GTAW process with 0Cr18Ni9Ti stainless steel. Int J Adv Manuf Technol 66:1545–1553

Zhang ZD, Zhang F (2009) Spectral analysis of welding plasma of magnesium alloy using flux coated wire. Mater Trans 50:1909–1914

Faraji AH, Goodarzi M, Seyedein SH, Zamani MH (2014) Experimental study and numerical modeling of arc and weld pool in stationary GTA welding of pure aluminum. Int J Adv Manuf Technol 71:2059–2071

Nishimura K (2001) Development of high efficient twin-arc TIG welding method. IIW Doc XI-783–03:78–87

Yamada K (2004) Practical application of high efficiency twin-arc TIG welding method (SEDAR-TIG) for PCLNG storage tank. IIIW Doc XII-1669–01:101–110

Leng XS, Zhang GJ, Wu L (2006) Experimental study on improving welding efficiency of twin electrode TIG welding method. Sci Technol Weld Join 11:550–554

Moulton JA, Weckman DC (2010) Double-sided arc welding of AA5182-0 aluminum sheet for tailor welded bland applications. Weld J 89:11–23

Chowdhury SM, Chen DL, Bhole SD, Cao X, Powidajko E, Weckman DC, Zhou Y (2010) Tensile properties and strain-hardening behavior of double-sided arc welded and friction stir welded AZ31B magnesium alloy. Mater Sci Eng A 527:2951–2961

Zhang YM, Zhang SB (1999) Method of arc welding using dual serial opposed torches. US Pat No 5:990,446

Zhang YM, Zhang SB (1998) Double-sided arc welding increases welding joint penetration. Weld J 77:57–61

Li CB, Liu LM (2013) Investigation on weldability of magnesium alloy thin sheet T-joints: arc welding, laser welding and laser-arc hybrid welding. Int J Adv Manuf Technol 65:27–34

Tan CW, Li LQ, Chen YB, Mei CX, Guo W (2013) Interfacial microstructure and fracture behavior of laser welded-brazed Mg alloys to Zn-coated steel. Int J Adv Manuf Technol 68:1179–1188

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, L., Chen, M., Li, C. et al. A new superimposed double-arc welding method with one arc submerged in the weld pool. Int J Adv Manuf Technol 75, 331–337 (2014). https://doi.org/10.1007/s00170-014-6116-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6116-9