Abstract

This work presents new research results from double-electrode gas tungsten arc welding, a process variant that was developed with the aim of improving productivity and welding speed. A welding torch specially constructed for research was used with total current in the range of 200–600 A. Tests using a high-speed camera were conducted in order to characterize the arc morphology at different distances between the electrodes. It could be seen that the morphology of the arc and the voltage drop in each electrode change significantly with the increase in the welding speed, especially when there is a larger clearance distance between electrodes. The resulting arc presented bigger asymmetry as the welding speed was increased. Bead-on-plate tests were performed in order to evaluate their susceptibility to humping defects. The results showed that in comparison with the conventional GTAW, the double-electrode process enables a considerable increase in the maximum speed, without defects—taking into consideration the total applied current. This shows that this new process has great potential for expanding the range of gas tungsten arc welding in high-productivity welding applications.

Similar content being viewed by others

References

Hori K, Watanabe H, Myoga T, Kusano K (2003) Development of hot wire TIG welding methods using pulsed current to heat filler wire—research on pulse heated hot wire TIG welding processes (report 1). Q J Jpn Weld Soc 21(3):362–373

Welding handbook (2004) Welding processes, part 1, vol 2, 9th edn. American Welding Society, Miami, p 117 ISBN: 0-87171-729-8

Shinozaki K, Yamamoto M, Mitsuhata K, Nagashima T, Kanazawa T, Arashin H (2011) Bead formation and wire temperature distribution during ultra-high-speed GTA welding using pulse-heated hot-wire. Weld World 55(04):12–18

Savage WF, Nippes EF, Agusa K (1979) Effect of arc force on defect formation in GTA welding. Weld J:212s–224s

Mendez PF, Eagar TW (2003) Penetration and defect formation in high-current arc welding. Weld J:296–306

Kumar A, Debroy T (2006) Toward a unified model to prevent humping defects in gas tungsten arc welding. Weld J:292–304

Soderstrom E, Mendez PF (2006) Humping mechanisms present in high speed welding. Sci Technol Weld Join 11(5):572–579

Lin ML, Eagar TW (1986) Pressures produced by gas tungsten arcs. Metall Trans B 17B(Set):601–607

Reis RP, Souza D, Scotti A (2011) Models to describe plasma jet, arc trajectory and arc blow formation in arc welding. Weld World 55(3/4):24–32

Fan HG, Shi YW (1996) Numerical simulation of the arc pressure in gas tungsten arc welding. J Mater Process Technol 61:302–308

Campbell SW, Galloway AM, McPherson NA (2013) Arc pressure and fluid flow during alternating shielding gases. Part 2: arc force determination. Sci Technol Weld Join 18(7):597–602

Zähr J, Füssel U, Hertel M, Lohse M, Sende M, Schnick M (2012) Numerical and experimental studies of the influence of process gases in TIG welding. Weld World 58(3/4):85–92

Leng XS, Zhang GJ, Wu L (2006) Experimental study on improving welding efficiency of twin electrode TIG welding method. Sci Technol Weld Join 11(5):550–554

Ogino Y, Hirata Y, Kawata J, Nomura K (2013) Numerical analysis of arc plasma and weld pool formation by a tandem TIG arc. Weld World 57:411–423

Kobayashi K, Nishimura Y, Iijima T, Ushio M, Tanaka M, Shimamura J, Ueno Y, Yamashita M (2004) Practical application of high efficiency twin-arc TIG welding method (sedar-TIG) for PCLNG storage tank. Weld World 48(7/8):35–39

Leng XS, Zhang GJ, Wu L (2006) The characteristic of twin-electrode TIG coupling arc pressure. J Phys D Appl Phys 39:1120–1126

Zhang G, Leng X, Wu L (2006) Physics characteristic of coupling arc of twin-tungsten TIG welding. Trans Nonferrous Metals Soc China 16:813–817

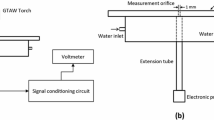

Schwedersky MB, G RH, e Silva JC, Dutra U, Reisgen KW (2016. ISSN: 1362–1718) Two-dimensional arc stagnation pressure measurements for the double-electrode GTAW process. Sci Technol Weld Join 21:275–280. https://doi.org/10.1080/13621718.2015.1104095

Schwedersky MB, Dutra JC, G RH, e Silva U, Reisgen KW (2015) Double-electrode process speeds GTAW. Weld J:64–67

Ogino Y, Hirata Y, Nomura K (2011) Numerical analysis of the heat source characteristics of a two-electrode TIG arc. J Phys D Appl Phys 44:215202

Wang X, Fan D, Huan J, Huang Y (2014) A unified model of coupled arc plasma and weld pool for double electrodes TIG welding. J Phys D Appl Phys 47:275202 (14pp)

Polysoude – TIGer brochure, Accessed 14 June 2014. http://fr.polysoude.com/images/stories/documents/french/technical/DOC_Broch_TIGer-technology_FR.pdf

Egerland S, Zimmer J, Brunmaier R, Nussbaumer R, Posch G, Rutzinger B (2015) Advanced gas tungsten arc weld surfacing current status and application. Soldagem Insp 20(3):300–314. https://doi.org/10.1590/0104-9224/SI2003.05

Funding

The authors gratefully acknowledge the financial support (scholarship) of CAPES (Brazilian Federal Agency for Support and Evaluation of Graduate Education) and the CNPq (National Council of Technological and Scientific Development).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schwedersky, M.B., Gonçalves e Silva, R.H., Dutra, J.C. et al. Arc characteristic evaluation of the double-electrode GTAW process using high current values. Int J Adv Manuf Technol 98, 929–936 (2018). https://doi.org/10.1007/s00170-018-2344-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2344-8