Abstract

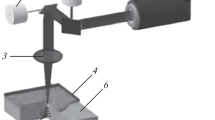

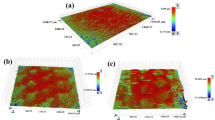

Recently, a number of magnesium-based alloys have been identified as a potential biodegradable material for implants. The challenge in the application of medical alloys is that these medical alloys corrode within human body much faster than duration of broken bones conglutination. In this regards, laser shock peening by increasing compressive residual stress upon biodegradable metallic implant surface had been proposed as a capable method for corrosion reduction. Laser shock peening is currently performed by high-power low-repetition rate lasers. Its high cost for applying on low-priced and light mechanical strength specimen is the main restrictions for its performance. This research is an attempt to theoretically ascertain the feasibility of laser shock peening (LSP) by high-repetition rate pulsed laser. Lower cost, faster processing speed, and accumulation of compressive residual stress closer to the surface by high repetition rate laser, combined with better corrosion control are the primary motivators for evaluation of the possibility of high repetition laser shock peening.

Similar content being viewed by others

References

Bugbee WD, Culpepper WJ, Engh CA Jr, Charles (1997) Long-term clinical consequences of stress-shielding after total hip arthroplasty without cement. J Bone Joint Surg

Salahshoor M, Guo Y (2012) Biodegradable orthopedic magnesium-calcium (MgCa) alloys, processing, and corrosion performance. Materials 5:135–155. doi:10.3390/ma5010135

Guo Y, Sealy MP, Guo C (2012) Significant improvement of corrosion resistance of biodegradable metallic implants processed by laser shock peening. Manuf Technol 61:583–586

Dwars A, Kochanowski W, Schramm B, Sehr F Application of thermally sprayed coatings of the type WC/Co Cr in reverse osmosis processes for seawater desalination. Mater Corros 59–2008

Qian M, Li D, Liu SB, Gong SL (2010) Corrosion performance of laser re-melted Al–Si coating on magnesium alloy AZ91D. Corros Sci 52:3554–3560

Zhang XP, Zhao ZP, Wu FM, Wang YL, Wu J (2007) Corrosion and wear resistance of AZ91D magnesium alloy with and without microarc oxidation coating in Hank’s solution. J Mater Sci 42(20):8523–8528

Wang H X, Guan S K, Wang X (2009) In vitro degradation and mechanical integrity of Mg-Zn-Ca alloy coated with Ca-deficient hydroxyapatite by the pulse electrodeposition process. Acta Biomater

Gu XN, Zheng YF, Lan QX et al (2009) Surface modification of Mg-1Ca alloy to slow down its biocorrosion by chitosan. Biomed Mater 4(4):044109

Xu L, Pan F, Yu G (2009) In vitro and in vivo evaluation of the surface bioactivity of a calcium phosphate coated magnesium alloy. Biomaterials 30(8):1512–1523

Hadzima B, Bukovina M, Doležal P (2010) Shot peening influence on corrosion resistance of AE21 magnesium alloy. Mater Eng 17 No. 4

Pu Z, Yang S, Song GL, Dillon OW Jr, Puleo DA, Jawahir IS (2011) Ultrafine-grained surface layer on Mg–Al–Zn alloy produced by cryogenic burnishing for enhanced corrosion resistance. Scr Mater 65:520–523

Fabbro R, Peyre P, Berthe L, Scherpereel X (1998) Physics and applications of laser-shock processing. J Laser Appl 10(6):265

Turski M, Clitheroe S, Evans AD, Rodopoulos C, Hughes DJ, Withers PJ (2010) Engineering the residual stress state and microstructure of stainless steel with mechanical surface treatments. Appl Phys A 99(3):549–556

Guo YB, Salahshoor M (2010) Process mechanics and surface integrity by high-speed dry milling of biodegradable magnesium–calcium implant alloys. CIRP Ann Manuf Technol 59(1):151–154

Song X, Liu WC, Belnoue JP, Dong J, Wu GH, Ding WJ, Kimber SAJ, Buslaps T, Lunt AJG, Korsunsky AM (2012) An eigenstrain-based finite element model and the evolution of shot peening residual stresses during fatigue of GW103 magnesium alloy. Int J Fatigue 42:284–295

Zhang P, Lindemann J, Ding WJ, Leyens C (2010) Effect of roller burnishing on fatigue properties of the hot-rolled Mg–12Gd–3Y magnesium alloy. Mater Chem Phys 124(1):835–840

Zhang P, Lindemann J (2005) Effect of roller burnishing on the high cycle fatigue performance of the high-strength wrought magnesium alloy AZ80. Scr Mater 52(10):1011–1015

Salahshoor M, Guo YB (2011) Surface integrity of biodegradable magnesium-calcium orthopedic implant by burnishing. J Mech Behav Biomed Mater 4(8):1888–1904

Salahshoor M, Guo YB (2011) Surface integrity of magnesium-calcium implants processed by synergistic dry cutting-finish burnishing. Procedia Eng 19:288–293

Salahshoor M, Guo YB (2012) Process mechanics in ball burnishing biomedical magnesium–calcium alloy. Int J Adv Manuf Technol 64(1–4):133–144

Kruusing A (2008) Handbook of liquids-assisted laser processing. Elsevier- ISBN: 978-0-08-044498-7

Uroš T, Janez G (2012) Evaluation of corrosion resistance of AA6082-T651 aluminum alloy after laser shock peening by means of cyclic polarisation and ElS methods. Corros Sci 59:324–333

Nikitin I, Scholtes B, Maier H, Altenberger I (2004) High temperature fatigue behavior and residual stress stability of laser-shock peened and deep rolled austenitic steel AISI 304. Scr Mater 50(10):1345–1350

Hyuntaeck L, Pilkyu K, Hoemin J, Sungho J (2012) Enhancement of abrasion and corrosion resistance of duplex stainless steel by laser shock peening. J Mater Process Technol 212:1347–1354

Montross CS, Wei T, Ye L, Clark G, Mai Y (2006) Laser shock processing and its effects on microstructure and properties of metal alloys: a review. 24 no. 2002, pp. 1021–1036

Sealy MP, Guo YB (2010) Surface integrity and process mechanics of laser shock peening of novel biodegradable magnesium-calcium (Mg-Ca) alloy. J Mech Behav Biomed Mater 3(7):488–496

Cook SD, Dalton JE (1992) Biocompatibility and biofunctionality of implanted materials. Alpha Omegan 85(4):41–47

Walter R, Kannan MB (2011) Influence of surface roughness on the corrosion behaviour of magnesium alloy. Mater Des 32(4):2350–2354

Guo Y, Sealy MP, Guo C (2012) Significant improvement of corrosion resistance of biodegradable metallic implants processed by laser shock peening. CIRP Ann Manuf Technol 61:583–586

Luo Q-Z, D’Angelo N, Merlinoa RL Shock formation in a negative ion plasma. Department of Physics and Astronomy-1998-The University of Iowa, USA- Physics of plasmas volume 5, number 8

Johnson JN, Rhode RW (1971) Dynamic deformation twinning in shock loaded iron. J Appl Phys 42:4171–4182

Ballard P (1991) Contraintes résiduelles induites par impact rapide: application au choc laser. Thèse de doctorat, École Polytechnique, Palaiseau, France 217 pp

Ballard P, Fournier J, Fabbro R et al (1991) Residual stresses induced by laser-shocks. J Phys IV (Coll) 1(C3):487–494

Shukla M et al (2006) Laser induced shock pressure multiplication in multi-layer thin foil targets. Nucl Fusion 46:419–431

Guo YB, Caslaru R (2011) Fabrication and characterization of micro dent arrays produced by laser shock peening on titanium Ti-6Al-4V surfaces. J Mater Process Technol 211:729–736

Din K, Ye L (2006) Laser shock peening performance and process simulation –book. www.Woodheadpublishing.com

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamkarrad, H., Narayanswamy, S. & Tao, X.S. Feasibility study of high-repetition rate laser shock peening of biodegradable magnesium alloys. Int J Adv Manuf Technol 74, 1237–1245 (2014). https://doi.org/10.1007/s00170-014-6051-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6051-9