Abstract

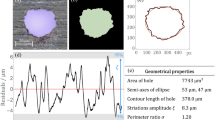

This study explored the feasibility of magnetic-field-assisted laser percussion drilling on highly reflective materials, i.e., Al5052. During laser percussion drilling, the Lorentz force generated by the assisting magnetic field affects the laser-induced plasma. A magnetic field simulation was performed to investigate the field strength of the circular hollow permanent magnet used herein. The influence of the magnetic field and laser radiation energy on the penetration depth and inlet diameter was examined. All experiments were performed in air without additional process gas. It was found that at laser radiation energy of 200 mJ with magnetic field assistance, the penetration depth could be increased by 87.7 % and the inlet diameter could be reduced by 23.7 % as compared with percussion drilling without the applied magnetic field. However, when the laser radiation energy was reduced to 120 mJ, the magnetic field confined the plasma plume; therefore, the penetration depth decreased.

Similar content being viewed by others

References

Panda S, Mishra D, Biswal BB (2011) Determination of optimum parameters with multi-performance characteristics in laser drilling—a grey relational analysis approach. Int J Adv Manuf Technol 54:957–967

Wendland J, Harrison PM, Henry M, Brownell M (2005) Deep engraving of metals for the automotive sector using high average power diode pumped solid state lasers. Proceedings of ICALEO

Ghany KA, Rafea HA, Newishy M (2006) Using a Nd:YAG laser and six axes robot to cut zinc-coated steel. Int J Adv Manuf Technol 28:1111–1117

Dubey AK, Yadava V (2008) Robust parameter design and multi-objective optimization of laser beam cutting for aluminium alloy sheet. Int J Adv Manuf Technol 38:268–277

Chang YJ, Kuo CL, Wang NY (2012) Magnetic assisted laser micromachining for highly reflective metals. J Laser Micro/Nanoeng 7:254–259

Pandey AK, Dubey AK (2013) Multiple quality optimization in laser cutting of difficult-to-laser-cut material using grey–fuzzy methodology. Int J Adv Manuf Technol 65:421–431

Thawari G, Sundar J, Sundararajan G, Joshi S (2005) Influence of process parameters during pulsed Nd:YAG laser cutting of nickel-base superalloys. J Mater Process Technol 170:229–239

Gu E, Jeona CW, Choia HW, Ricea G, Dawsona MD, Illyb EK, Knowlesb MRH (2004) Micromachining and dicing of sapphire, gallium nitride and micro LED devices with UV copper vapour laser. Thin Solid Films 453:462–466

Zhu X, Villeneuve D, Naumov AY, Nikumb S, Corkum P (1999) Experimental study of drilling sub-10 μm holes in thin metal foils with femtosecond laser pulses. Appl Surf Sci 152:138–148

Tse H, Man H, Yue T (1999) Effect of magnetic field on plasma control during CO2 laser welding. Opt Laser Technol 31:363–368

Zhou J, Tsai H-L (2007) Effects of electromagnetic force on melt flow and porosity prevention in pulsed laser keyhole welding. Int J Heat Mass Transfer 50:2217–2235

Tsui Y, Minami H, Vick D, Fedosejevs R (2002) Debris reduction for copper and diamond-like carbon thin films produced by magnetically guided pulsed laser deposition. J Vac Sci Technol A Vacuum Surf Films 20:744–747

García T, de Posada E, Villagran M, Ll J, Bartolo-Pérez P, Peña J (2008) Effects of an external magnetic field in pulsed laser deposition. Appl Surf Sci 255:2200–2204

Harilal S, Tillack M, O’Shay B, Bindhu C, Najmabadi F (2004) Confinement and dynamics of laser-produced plasma expanding across a transverse magnetic field. Phys Rev E 69(026413):1–11

Qindeel R, Bidin NB, Daud YM (2008) Dynamic expansion of laser produced plasma with different materials in magnetic field. J Phys Conf Ser 142:012069

Pandey PK, Thareja R (2011) Plume dynamics and cluster formation in laser-ablated copper plasma in a magnetic field. J Appl Phys 109:074901

Pagano C, Hafeez S, Lunney J (2009) Influence of transverse magnetic field on expansion and spectral emission of laser produced plasma. J Phys D Appl Phys 42:155205

Mostovych A, Ripin B, Stamper J (1989) Laser produced plasma jets: collimation and instability in strong transverse magnetic fields. Phys Rev Lett 62:2837–2840

Pagano C, Lunney J (2010) Lateral confinement of laser ablation plasma in magnetic field. J Phys D Appl Phys 43:305202

Niemax K, Sdorra W (1990) Optical emission spectrometry and laser-induced fluorescence of laser produced sample plumes. Appl Opt 29:5000–5006

Cicală E, Soveja A, Sallamand P, Grevey D, Jouvard J-M (2008) The application of the random balance method in laser machining of metals. J Mater Process Technol 196(1):393–401

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ho, CC., Tseng, GR., Chang, YJ. et al. Magnetic-field-assisted laser percussion drilling. Int J Adv Manuf Technol 73, 329–340 (2014). https://doi.org/10.1007/s00170-014-5815-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5815-6