Abstract

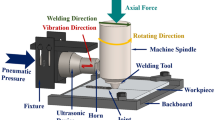

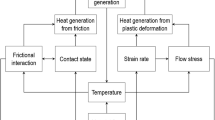

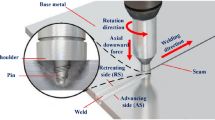

Ultrasonic-assisted friction-stir welding is a new solid-state metal welding technology, based on friction-stir welding, in which weld performance is improved through application of ultrasound during welding. In this study, a model for the temperature field in 1.8 mm 2024 aluminum alloy is built based on computational fluid dynamics and elastic-plastic mechanics theory. Result show the impact of the ultrasound’s vibrations on the temperature field is less obvious at lower welding speeds. However, at higher welding speeds, it can provide the additional heat to keep sufficient welding temperature. The numerical results are compared with optical micrographs in order to validate the numerical models. Good agreement is obtained.

Similar content being viewed by others

References

He DQ (2006) Supersonic stirring welding method and its device. China, Patent: 200610004059.3

Zhang Z, Zhang HW (2008) A fully coupled thermo-mechanical model of friction stir welding. Int J Adv Manuf Technol. doi:10.1007/s00170-007-0971-6

Assidi M, Fourment L, Guerdoux S (2010) Friction model for friction stir welding process simulation: calibrations from welding experiments. Int J Mach Tools Manuf 50:143–155

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Neto DM, Neto P (2013) Numerical modeling of friction stir welding process: a literature review. Int J Adv Manuf Technol 65:115–126

Frigaard Ø, Grong Ø, Midling OT (2001) A process model for friction stirs welding of age hardening aluminum alloys. Metall Mater Trans A 32A(5):1189–1200. doi:10.1007/s11661-001-0128-4

Song M, Kovacevic R (2003) Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int J Mach Tools Manuf 43:605–615

Zhang HW, Zhang Z, Chen JT (2005) The finite element simulation of the friction stir welding process. Mater Sci Eng A 403(1–2):340–348

Schmidt H, Hattel J (2005) Modeling heat flow around tool probe in friction stir welding. Sci Technol Weld Join 10(2):176–186

Jacquin D, de Meester B, Simar A, Deloison D, Montheillet F, Desrayaud C (2011) A simple Eulerian thermomechanical modeling of friction stir welding. J Mater Process Technol 211:57–65

Zhang XX, Xiao BL, Ma ZY (2011) A transient thermal model for friction stir welding. Part I: the model. Metall Mater Trans A 42A:3218–3228

Mandal S, Rice J, Elmustafa AA (2008) Experimental and numerical investigation of the plunge stage in friction stir welding. J Mater Process Technol 23:411–419

Park K (2009) Development and analysis of ultrasonic assisted friction stir welding process. The University of Michigan, Michigan

Park K (2008) Numerical simulation of plunge force during the plunge phase of friction stir welding and ultrasonic assisted FSW. ASME International Mechanical Engineering Congress and Exposition, Boston, USA, October 31-Novmber 6

Veljić DM, Perović MM, Sedmak AS, Rakin MP, Trifunović MV, Bajić NS, Bajić DR (2012) A coupled thermo-mechanical model of friction stir welding. Therm Sci 16(2):527–534. doi:10.2298/TSCI110729012V

Schmidt H, Hattel J, Wert J (2004) An analytical model for the heat generation in friction stir welding. Model Simul Mater Sci Eng 12:143–157. doi:10.1088/0965-0393/12/1/013

Soundararajan V, Zekovic S, Kovacevic R (2005) Thermo-mechanical model with adaptive boundary conditions for friction stir welding of al 6061. Int J Mach Tools Manuf 45:1577–1587

Reynolds AP (2006) Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Metall Mater Trans A Phys Metall Mater Sci 32(11):2879–2884

Sheppard T, Jackson A (1997) Constitutive equations for use in prediction of flow stress during extrusion of aluminium alloys. Mater Sci Technol 13:203–209

Prasanna P, Subba Rao B, Krishna Mohana Rao G (2010) Finite element modeling for maximum temperature in friction stir welding and its validation. Int J Adv Manuf Technol 51:925–933

Πерлин И Л (1964) Теория прессования металлов.Металлургяя

Jamshidi Aval H, Serajzadeh S, Kokabi AH (2011) Theoretical and experimental investigation into friction stir welding of AA 5086. Int J Adv Manuf Technol 52:531–544

Zhang Z, Liu YL, Chen JT (2009) Effect of shoulder size on the temperature rise and the material deformation in friction stir welding. Int J Adv Manuf Technol 45:889–895

Fehrenbacher A, Duffie NA, Ferrier NJ, Pfefferkorn FE, Zinn MR (2013) Effects of tool–workpiece interface temperature on weld quality and quality improvements through temperature control in friction stir welding. Int J Adv Manuf Technol 71:165

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ruilin, L., Diqiu, H., Luocheng, L. et al. A study of the temperature field during ultrasonic-assisted friction-stir welding. Int J Adv Manuf Technol 73, 321–327 (2014). https://doi.org/10.1007/s00170-014-5813-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5813-8