Abstract

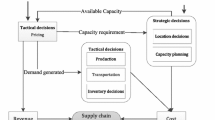

Logistics network design is a major strategic issue due to its impact on the efficiency and responsiveness of the supply chain. This paper focuses on strategic and tactical design of steel supply chain (SSC) networks. Ever-increasing demand for steel products enforces the steel producers to expand their production and storage capacities. The main purpose of the paper includes preparing a countrywide production, inventory, distribution, and capacity expansion plan to design an SSC network. The SSC networks consist of iron ore mines as suppliers, raw steel producer companies as producers, and downstream steel companies as customers. Demand is assumed stochastic with normal distribution and known at the beginning of planning horizon. To achieve the service level of interest, a potential production capacity along with two kinds of safety stocks including emergency and shared safety stocks are suggested by the authors. A mixed integer nonlinear programming (MINLP) model and a mixed integer linear programming (MILP) model are presented to design dynamic multi-commodity SSC networks. To evaluate the performance of the MILP model, a real case of SSC network design is solved. Furthermore, solving two proposed models by using a commercial solver for a set of numerical test cases shows that the MILP model outperforms MINLP in medium- and large-scale problems in terms of computational time. Finally, the complexity of the linear model is investigated by relaxing some major assumptions.

Similar content being viewed by others

References

Shavandi H, Bozorgi B (2012) Developing a location–inventory model under fuzzy environment. Int J Adv Manuf Technol 63:191–200

Sabri EH, Beamon BM (2000) A multi-objective approach to simultaneous strategic and operational planning in supply chain design. Omega 28:581–598

Chopra S, Meindl P (2007) Supply chain management: strategy, planning, and operation, 3rd edn. Prentice-Hall, New York

Melo MT, Nickel S, Saldanha da Gama F (2009) Facility location and supply chain management—a review. Eur J Oper Res 196:401–412

Jayaraman V, Pirkul H (2001) Planning and coordination of production and distribution facility for multiple commodities. Eur J Oper Res 133:394–408

Erlebacher SJ, Meller RD (2000) The interaction of location and inventory in designing distribution systems. IIE Trans 32:155–166

Syam SS (2002) A model and methodologies for the location problem with logistical components. Comput Oper Res 29:1173–1193

Melo MT, Nickel S, Saldanha da Gama F (2005) Dynamic multi-commodity capacitated facility location: a mathematical modeling framework for strategic supply chain planning. Comput Oper Res 33:181–208

Cordeau JF, Pasin F, Solomon MM (2006) An integrated model for logistics network design. Ann Oper Res 144:59–82

Gabor AF, Van Ommeren JCW (2006) An approximation algorithm for a facility location problem with stochastic demands and inventories. Oper Res Lett 34:257–263

Thanh PN, Bostel N, Peton O (2008) A dynamic model for facility location in the design of complex supply chains. Int J Prod Econ 113:678–693

Liu CM, Sherali HD (2000) A coal shipping and blending problem for an electric utility company. Omega 28:433–444

Bilgen B (2006) An iterative fixing variable heuristic for solving a combined blending and distribution planning problem. Proceedings of the 6th International Conference on Numerical Methods and Applications, pp 231–238

Movafagh Pour MA, Farahani RZ (2007) Designing and solving a model for facility location, inventory and transportation in bulk material supply chain. Proceedings of the 5th International Industrial Engineering Conference, July 2007, Tehran, Iran

Arabani AB, Farahani RZ (2012) Facility location dynamics: an overview of classifications and applications. Comput Indu Eng 62:408–420

Boudia M, Prins C (2009) A memetic algorithm with dynamic population management for an integrated production-distribution problem. Eur J Oper Res 195:703–715

Liang TF, Cheng HW (2009) Application of fuzzy sets to manufacturing/distribution planning decisions with multi-product and multi-time period in supply chain. Expert syst appl 36:3367–3377

Gendron B, Semet F (2009) Formulations and relaxations for a multi-echelon capacitated location–distribution problem. Comput Oper Res 36:1335–1355

Hinojosa Y, Kalcsics J, Nickel S, Puerto J, Velten S (2008) Dynamic supply chain design with inventory. Comput Oper Res 35:373–391

Kutanoglu E, Lohiya D (2008) Integrated inventory and transportation mode selection: a service parts logistics system. Trans Res Part E 44:665–683

Eksioglu SD, Eksioglu B, Romeijn HE (2007) A Lagrangian heuristic for integrated production and transportation planning problem in a dynamic, multi-item, two-layer supply chain. IIE Trans 39:191–201

Snyder LV, Daskin MS, Chung-Piaw T (2007) The stochastic location model with risk pooling. Eur J Oper Res 179:1221–1238

Bilgen B, Ozkarahan I (2007) A mixed-integer linear programming model for bulk grain blending and shipping. Int J Prod Econ 107:555–571

Vila D, Martel A, Beauregard R (2006) Designing logistics network in divergent process industry: a methodology and its application to the lumber industry. Int J Prod Econ 102:358–378

Persson JA, Lundgren MG (2005) Shipment planning at oil refineries using column generation and valid inequalities. Eur J Oper Res 163:631–652

Lee YH, Kim SH (2002) Production–distribution planning in supply chain considering capacity constraints. Comput Ind Eng 43:169–190

Nozick LK, Turnquist MA (2001) Inventory, transportation, service quality and the location of distribution centers. Eur J Oper Res 129:362–371

Sadjady H, Davoudpour H (2012) Two-echelon, multi-commodity supply chain network design with mode selection, lead-times and inventory costs. Comput Oper Res 39:1345–1354

Zhang J, Liu X, Tu YL (2011) A capacitated production planning problem for closed-loop supply chain with remanufacturing. Int J Adv Manuf Technol 54:757–766

Atighechian A, Bijari M, Tarkesh H (2009) A novel hybrid algorithm for scheduling steel-making continuous casting production. Comput Oper Res 36:2450–2461

Weingartner HM (1963) Mathematical programming and the analysis of capital budgeting problems. Prentice-Hall, New York

Park CS, Sharp-Bette GP (1990) Advanced engineering economics. Wiley, New York

Sabzevari Zadeh A, Sahraeian R (2010) A general model for production–transportation planning in steel supply chain. Int J Iron and Steel Society of Iran 7(1):11–16

Li D, Sun X (2006) Non-linear integer programming. Springer, New York

Fisher ML (1997) What is the right supply chain for your product. Harvard Business Review, Boston

Stoer J, Bulirsch R (2002) Introduction to numerical analysis, 3rd edn. Springer, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sabzevari Zadeh, A., Sahraeian, R. & Homayouni, S.M. A dynamic multi-commodity inventory and facility location problem in steel supply chain network design. Int J Adv Manuf Technol 70, 1267–1282 (2014). https://doi.org/10.1007/s00170-013-5358-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5358-2