Abstract

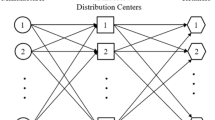

This paper deals with the supply chain network design and planning for a multi-commodity and multi-layer network over a planning horizon with multiple periods in which demands of customer zones are considered to be price dependent. These prices determine the demands using plausible price–demand relationships of customer zones. The net income of the supply chain is maximized, while satisfying budget constraints for investment in network design. In addition, a new approach is considered for capacity planning to make the problem more realistic. In this regard, when production plants are opened and expanded, capacity options are taken into account for manufacturing operations. Furthermore, several aspects relevant to real world applications are captured in the problem. Different interconnected time periods in the planning horizon are considered for strategic and tactical decisions in the problem and then, a mixed-integer linear programming (MILP) model is developed. The performance and applications of the model are investigated by several test problems with reasonable sizes. The numerical results illustrate that obtained solutions after solving the MILP model by using CPLEX solver are acceptable. Moreover, using an alternative pricing approach, a tight upper bound is provided for the problem. In addition, a deep sensitivity analysis is conducted to show the validity and performance of the proposed model.

Similar content being viewed by others

References

Abouei Ardakan, M., Hakimian, A., & Rezvan, M. T. (2013). A branch-and-bound algorithm for minimising the number of tardy jobs in a two-machine flow-shop problem with release dates. International Journal of Computer Integrated Manufacturing, 27(6), 519–528. doi:10.1080/0951192x.2013.820349.

Aghezzaf, E. (2005). Capacity planning and warehouse location in supply chains with uncertain demands. Journal of the Operational Research Society, 56(4), 453–462.

Ahmadi-Javid, A., & Ghandali, R. (2014). An efficient optimization procedure for designing a capacitated distribution network with price-sensitive demand. Optimization and Engineering, 15(3), 801–817. doi:10.1007/s11081-013-9245-3.

Ahmadi-Javid, A., & Hoseinpour, P. (2015). Incorporating location, inventory and price decisions into a supply chain distribution network design problem. Computers and Operations Research, 56, 110–119. doi:10.1016/j.cor.2014.07.014.

Akçalı, E., Çetinkaya, S., & Üster, H. (2009). Network design for reverse and closed-loop supply chains: An annotated bibliography of models and solution approaches. Networks, 53(3), 231–248.

Badri, H., Bashiri, M., & Hejazi, T. H. (2013). Integrated strategic and tactical planning in a supply chain network design with a heuristic solution method. Computers and Operations Research, 40(4), 1143–1154.

Ballou, R. H. (1968). Dynamic warehouse location analysis. Journal of Marketing Research (JMR), 5(3), 271–276.

Bashiri, M., Badri, H., & Talebi, J. (2012). A new approach to tactical and strategic planning in production-distribution networks. Applied Mathematical Modelling, 36(4), 1703–1717.

Canel, C., Khumawala, B. M., Law, J., & Loh, A. (2001). An algorithm for the capacitated, multi-commodity multi-period facility location problem. Computers and Operations Research, 28(5), 411–427.

Chardaire, P., Sutter, A., & Costa, M. C. (1996). Solving the dynamic facility location problem. Networks, 28(2), 117–124.

Correia, I., Melo, T., & Saldanha-da-Gama, F. (2013). Comparing classical performance measures for a multi-period, two-echelon supply chain network design problem with sizing decisions. Computers and Industrial Engineering, 64(1), 366–380.

Dias, J., Eugénia Captivo, M., & Clímaco, J. (2007). Efficient primal-dual heuristic for a dynamic location problem. Computers and Operations Research, 34(6), 1800–1823.

Esmaeilikia, M., Fahimnia, B., Sarkis, J., Govindan, K., Kumar, A., & Mo, J. (2014). Tactical supply chain planning models with inherent flexibility: Definition and review. Annals of Operations Research, 1–21. doi:10.1007/s10479-014-1544-3.

Galvao, R. D., & Santibanez-Gonzalez, E. R. (1992). A Lagrangean heuristic for the \(p_k\)-median dynamic location problem. European Journal of Operational Research, 58(2), 250–262.

Georgiadis, M. C., Tsiakis, P., Longinidis, P., & Sofioglou, M. K. (2011). Optimal design of supply chain networks under uncertain transient demand variations. Omega, 39(3), 254–272.

Goetschalckx, M., Vidal, C. J., & Dogan, K. (2002). Modeling and design of global logistics systems: A review of integrated strategic and tactical models and design algorithms. European Journal of Operational Research, 143(1), 1–18.

Hanjoul, P., Hansen, P., Peeters, D., & Thisse, J.-F. (1990). Uncapacitated plant location under alternative spatial price policies. Management Science, 36(1), 41–57.

Hansen, P., Peeters, D., & Thisse, J. F. (1997). Facility location under zone pricing. Journal of Regional Science, 37(1), 1–22.

Hansen, P., Thisse, J.-F., & Hanjoul, P. (1981). Simple plant location under uniform delivered pricing. European Journal of Operational Research, 6(2), 94–103.

Hinojosa, Y., Kalcsics, J., Nickel, S., Puerto, J., & Velten, S. (2008). Dynamic supply chain design with inventory. Computers and Operations Research, 35(2), 373–391.

Hinojosa, Y., Puerto, J., & Fernández, F. R. (2000). A multiperiod two-echelon multicommodity capacitated plant location problem. European Journal of Operational Research, 123(2), 271–291.

Keyvanshokooh, E., Fattahi, M., Seyed-Hosseini, S. M., & Tavakkoli-Moghaddam, R. (2013). A dynamic pricing approach for returned products in integrated forward/reverse logistics network design. Applied Mathematical Modelling, 37(24), 10182–10202. doi:10.1016/j.apm.2013.05.042.

Longinidis, P., & Georgiadis, M. C. (2011). Integration of financial statement analysis in the optimal design of supply chain networks under demand uncertainty. International Journal of Production Economics, 129(2), 262–276.

Melo, M., Nickel, S., & Saldanha-da-Gama, F. (2012). A tabu search heuristic for redesigning a multi-echelon supply chain network over a planning horizon. International Journal of Production Economics, 136(1), 218–230.

Melo, M. T., Nickel, S., & Saldanha-Da-Gama, F. (2009). Facility location and supply chain management: A review. European Journal of Operational Research, 196(2), 401–412.

Melo, M. T., Nickel, S., & Saldanha-da-Gama, F. (2014). An efficient heuristic approach for a multi-period logistics network redesign problem. TOP, 22(1), 80–108. doi:10.1007/s11750-011-0235-3.

Melo, M. T., Nickel, S., & Saldanha da Gama, F. (2006). Dynamic multi-commodity capacitated facility location: A mathematical modeling framework for strategic supply chain planning. Computers and Operations Research, 33(1), 181–208.

Nickel, S., Saldanha-da-Gama, F., & Ziegler, H.-P. (2012). A multi-stage stochastic supply network design problem with financial decisions and risk management. Omega, 40(5), 511–524.

Phillips, R. (2005). Pricing and revenue optimization. Redwood City: Stanford University Press.

Pimentel, B. S., Mateus, G. R., & Almeida, F. A. (2013). Stochastic capacity planning and dynamic network design. International Journal of Production Economics, 145(1), 139–149.

ReVelle, C. S., Eiselt, H. A., & Daskin, M. S. (2008). A bibliography for some fundamental problem categories in discrete location science. European Journal of Operational Research, 184(3), 817–848. doi:10.1016/j.ejor.2006.12.044.

Salema, M. I. G., Barbosa-Povoa, A. P., & Novais, A. Q. (2010). Simultaneous design and planning of supply chains with reverse flows: A generic modelling framework. European Journal of Operational Research, 203(2), 336–349.

Schütz, P., Tomasgard, A., & Ahmed, S. (2009). Supply chain design under uncertainty using sample average approximation and dual decomposition. European Journal of Operational Research, 199(2), 409–419.

Scott, A. J. (1971). Dynamic location–allocation systems: Some basic planning strategies. Environment and Planning, 3(1), 73–82.

Shen, Z.-J. M. (2006). A profit-maximizing supply chain network design model with demand choice flexibility. Operations Research Letters, 34(6), 673–682.

Talluri, K. T., & Ryzin, G. J. (2006). The theory and practice of revenue management (Vol. 68). Berlin: Springer.

Tang, L., Jiang, W., & Saharidis, G. D. (2013). An improved Benders decomposition algorithm for the logistics facility location problem with capacity expansions. Annals of Operations Research, 210(1), 165–190. doi:10.1007/s10479-011-1050-9.

Thanh, P. N., Bostel, N., & Péton, O. (2008). A dynamic model for facility location in the design of complex supply chains. International Journal of Production Economics, 113(2), 678–693.

Thanh, P. N., Péton, O., & Bostel, N. (2010). A linear relaxation-based heuristic approach for logistics network design. Computers and Industrial Engineering, 59(4), 964–975.

Vila, D., Martel, A., & Beauregard, R. (2006). Designing logistics networks in divergent process industries: A methodology and its application to the lumber industry. International Journal of Production Economics, 102(2), 358–378.

Wagner, J., & Falkson, L. (1975). The optimal nodal location of public facilities with price-sensitive demand. Geographical Analysis, 7(1), 69–83.

Wilhelm, W., Han, X., & Lee, C. (2013). Computational comparison of two formulations for dynamic supply chain reconfiguration with capacity expansion and contraction. Computers and Operations Research, 40(10), 2340–2356. doi:10.1016/j.cor.2013.04.011.

Zarandi, M. F., Mosadegh, H., & Fattahi, M. (2013). Two-machine robotic cell scheduling problem with sequence-dependent setup times. Computers and Operations Research, 40(5), 1420–1434.

Zhang, S. (2001). On a profit maximizing location model. Annals of Operations Research, 103(1–4), 251–260. doi:10.1023/a:1012963324046.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Pricing parameters

In the pricing framework, in each tactical period, each customer zone has a willingness to pay distribution function for each product. Therefore, a price–demand relation is assumed for any customer in each time period and for each product. The relation between price \((P_{i, k,p, t} )\) and demand \((D_{i, k,p, t} )\) can be generally illustrated as in Fig. 17. This price response function is a special case of logit function. For more detailed explanations, one can refer to Phillips (2005) and Talluri and Ryzin (2006).

In the test problems, \(DMAX_{i, k,p, t} ,a_{i, k,p, t} ,\) and \(b_{i, k,p, t}\) are generated as \(DMAX_{i, k,p, t} \sim U\left( {500,1200} \right) \), \(a_{i, k,p, t} \sim U\left( {140,150} \right) \), and \(b_{i, k,p, t} \sim U\left( {190,200} \right) \), successively. Since a unique price for all customers is considered in the optimization problem to avoid cannibalization and arbitrage opportunity, the assumed price levels for all customers are the similar in each time period. Therefore, in each time period and for each product, the price level l is obtained as follows:

In each time period, the customer product demand for every price level should be obtained using the corresponding price-response function. Figure 18 shows the levels of price and demand for customer i and product k in strategic period p and tactical period t.

Appendix 2

See Table 7.

Rights and permissions

About this article

Cite this article

Fattahi, M., Mahootchi, M. & Moattar Husseini, S.M. Integrated strategic and tactical supply chain planning with price-sensitive demands. Ann Oper Res 242, 423–456 (2016). https://doi.org/10.1007/s10479-015-1924-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-015-1924-3