Abstract

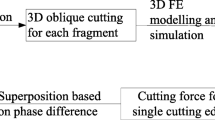

This paper presented a study of the relationship between cutting force and tool flank wear of solid carbide tool during the wet end milling Ti6Al4V. The modeling of 3D cutting force in end milling considering tool flank wear was discussed, which showed that for the given cutting conditions, tool geometries, and workpiece material, cutting force under the tool flank wear effect can be predicted easily and conveniently. In addition, the experimental work of end milling Ti6Al4V with solid carbide tool was developed to investigate the relationship between cutting force and tool flank wear, and comparison between experimental results and predicted results was discussed. The results showed that the proposed mathematical model can help to predict 3D cutting force under the tool flank wear effect with high accuracy.

Similar content being viewed by others

References

Hong H, Riga AT, Cahoon JM, Scott CG (1993) Machinability of steels and titanium alloys under lubrication. Wear 162:34–39

Oraby SE, Hayhurst DR (1991) Tool wear and force relationship in metal cutting. Int J Mech Sci 33(1):125–138

Teitenberg M, Bayoumi AE, Yucessan G (1992) Tool wear modeling through analytical mechanistic model of milling process. Wear 154:287–304

Waldorf DJ (1996) Shearing, ploughing and wear in orthogonal machining. PhD thesis, University of Illinois at Urbana-Champaign

Smithey DW, Kapoor SG, DeVor RE (2000) A worn tool force model for three-dimensional cutting operations. Int J Mach Tools Manuf 40:1929–1950

Youn JW, Yang MY (2001) A study on the relationships between static/dynamic cutting force components and tool wear. J Manuf Sci Eng 123:196–205

Davim JP, Monteiro BA (2000) Relationship between cutting force and PCD cutting tool wear in machining silicon carbide reinforced aluminum. J Mater Proc Technol 103:417–423

Wang J, Huang CZ, Song WG (2003) The Effect of tool flank wear on the orthogonal cutting process and its practical implications. J Mater Proc Technol 142:338–346

Huang Y, Liang SY (2005) Modeling of cutting forces under hard turning conditions considering tool wear effect. J Manuf Sci Eng 127:262–270

Song WG (2006) Development of predictive force models for classical orthogonal and oblique cutting and turning operations incorporating tool flank wear effects. PhD thesis, School of Engineering Systems, Queensland University of Technology

Belmonte M, Oliveira FJ, Sacramento J, Fernandes AJS, Silva RF (2004) Cutting forces evolution with tool wear in sintered hardmetal turning with CVD diamond. Diamond Relat Mater 13:843–847

Lalwani DI, Mehta NK, Jain PK (2008) Experimental investigations of cutting parameters influence on cutting forces and surface roughness in finish hard turning of MDN250 steel. J Mater Proc Technol 206:167–179

Sun J, Guo YB (2009) Material flow stress and failure in multiscale machining titanium alloy Ti-6Al-4V. Int J Adv Manuf Technol 41:651–659

Chen G, Ren CZ, Yang XY, Jin XM, Guo T (2011) Finite element simulation of high-speed machining of titanium alloy (Ti-6Al-4V) based on ductile failure model. Int J Adv Manuf Technol 56:1027–1038

Huang PL, Li JF, Sun J, Song LY (2012) Milling force vibration analysis in high-speed-milling titanium alloy using variable pitch angle mill. Int J Adv Manuf Technol 58(1):153–160

Siddhpura A, Paurobally R (2013) A review of flank wear prediction methods for tool condition monitoring in a turning process. Int J Adv Manuf Technol 65:371–393

Zhang S, Li JF, Wang YW (2012) Tool life and cutting forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. J Clean Prod 32:81–87

Turchetta S (2012) Cutting force and diamond tool wear in stone machining. Int J Adv Manuf Technol 61:441–448

Cui XB, Zhao J, Tian XH (2013) Cutting forces, chip formation, and tool wear in high-speed face milling of AISI H13 steel with CBN tools. Int J Adv Manuf Technol 64:1737–1749

Altintas Y (2000) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design, 1st edn. Cambridge University Press, Cambridge

Budak E, Altinta Y, Armarego EJA (1996) Prediction of milling force coefficients from orthogonal cutting data. Trans ASME 118:216–224

Stabler GV (1964) The chip flow law and its consequences. Adv Mach Tool Des Res 216–224

ISO3685 (1993) Tool-life testing with single-point turning tools

Li HZ, Zeng H, Chen XQ (2006) An experimental study of tool wear and cutting force variation in the end milling of Inconel 718 with coated carbide inserts. J Mater Proc Technol 180:296–304

Li KM, Liang SY (2007) Modeling of cutting forces in near dry machining under tool wear effect. Int J Mach Tools Manuf 47:1292–1301

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y., Sun, J., Li, J. et al. Modeling of cutting force under the tool flank wear effect in end milling Ti6Al4V with solid carbide tool. Int J Adv Manuf Technol 69, 2545–2553 (2013). https://doi.org/10.1007/s00170-013-5228-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5228-y