Abstract

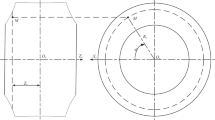

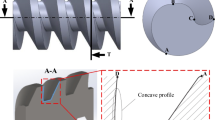

Widely increased use of screw components with complex helical surfaces in contemporary machinery makes a huge demand for high-efficiency fabrication of these components. In this paper, a typical whirling process is introduced and the helical surface of a screw shaft is mathematically modeled based on its axial section profile, which is depicted usually by a number of sampled points. Following this, a theoretical approach is proposed to whirling the screw by using standard cutters, aligned with a detailed investigation into related issues including calculations of the cross section profile and the cutting tool location points. In this approach, the helical surface can be generated according to the shaft cross section which is used as the envelope of the cutting-tool motions in the machining process. The machining error is also analyzed with focuses on the axial- and cross section scallop height. Finally a case study is presented, which demonstrates the whole process including CAD models and cutting tool in-process positioning geometry data. The error distribution of the machined component along the profiles is also simulated.

Similar content being viewed by others

References

Yi X, Ma W, Qi H, Yan Z, Gao D (2008) Equivalent normal curvature approach milling model of machining freeform surfaces. Chin J Mech Eng 21:52–57

Ivanov V, Nankov G (1998) Profiling of rotation tools for forming of helical surfaces. Int J Mach Tools Manuf 38:1125–1148

Sun Y, Wang J, Guo D, Zhang Q (2008) Modeling and numerical simulation for the machining of helical surface profiles on cutting tools. Int J Adv Manuf Technol 36:525–534

Zhang W, Wang X, He F, Xiong D (2006) A practical method of modeling and simulation for drill fluting. Int J Mach Tools Manuf 46:667–672

Oancea N, Popa I, Teodor V, Oancea V (2010) Tool profiling for generation of discrete helical surfaces. Int J Adv Manuf Technol 50:37–46

Teodor V, Popa I, Oancea N (2010) The profiling of end mill and planing tools to generate helical surfaces known by sampled points. Int J Adv Manuf Technol 51:439–452

Dong L, Wang J, Liu P, Wei W, Li H (2012) An NC rough turning method of an enveloping toroidal worm. Prod Eng Res Devel 6:129–135

Berbinschi S, Teodor V, Oancea N (2012) A study on helical surface generated by the primary peripheral surfaces of ring tool. Int J Adv Manuf Technol 61:15–24

Wehmann R (2012) The whirling process for improved worm gears. Leistriz Corporation. http://www.leistritzcorp.com/pdf/leistritzin_gearsolution.pdf. Accessed 20 August 2012

Mohan LV, Shunmugam MS (2007) Simulation of whirling process and tool profiling for machining of worms. J Mater Process Tech 185:191–197

Wang K, Wang S, Sun X, Liu G (2012) Machining theory of forming complex inner helicoid and numerical algorithm to design contour of the disc-mill cuter. Appl Mech Mater 141:339–43

Felix C. Whirling as a separate operation. http://www.productionmachining.com/articles/whirling-as-a-separate-operation. Accessed 20 August 2012

Hanson K. Thread whirling boosts productivity. http://www.index-werke.de/mediadata/tnl12-0030e.pdf. Accessed 20 August 2012

Yi X, Xu T, Ma W, Yan Z, Gao D (2010) 5-axis CNC Whirlwind milling method on helical surfaces of PDM's Rotors. 2010 International Conference on Measuring Technology and Mechatronics Automation, March 13-March 14, Changsha, ICMTMA, vol. 1, pp.7–10

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, Q., Liu, R. Theoretical model for CNC whirling of screw shafts using standard cutters. Int J Adv Manuf Technol 69, 2437–2444 (2013). https://doi.org/10.1007/s00170-013-5214-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5214-4