Abstract

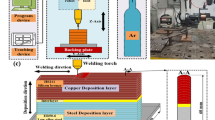

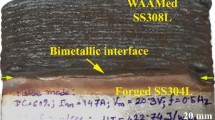

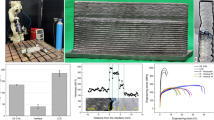

In this paper, mild steel–silicon bronze bimetal based on the single-pass multi-layer model was fabricated by shaped metal deposition utilizing gas metal arc welding technology. Suitable deposition parameters of silicon bronze were chosen to match the specific size of mild steel wall. Then the characteristics of interface were analyzed. The results show that Cu element did not exist on the steel side, but Fe element entered the bronze side in the forms of particles and big chunks. Meanwhile, owing to the physical and chemical reasons, the silicon element concentrated in the intermixing zone and on the bronze side where Fe element appeared. The interface between steel and bronze had good adhesion without cracks or pores, and metallurgical bonding was achieved. The tensile strength of the bimetal reached 305 MPa and fracture occurred near the middle of bronze side, implying a firm connection between steel and bronze was obtained.

Similar content being viewed by others

References

Simsir M, Kumruoglu LC, Ozer A (2009) An investigation into stainless-steel/structural-alloy-steel bimetal produced by shell mould casting. Mater Des 30:264–270

Khosravifard A, Ebrahimi R (2010) Investigation of parameters affecting interface strength in Al/Cu clad bimetal rod extrusion process. Mater Des 31:493–499

Kore SD, Date PP, Kulkarni SV, Kumar S, Rani D, Kulkarni MR, Desai SV, Rajawat RK, Nagesh KV, Chakravarty DP (2011) Application of electromagnetic impact technique for welding copper-to-stainless steel sheets. Int J Adv Manuf Technol 54:949–955

Imran MK, Masood SH, Brandt M (2011) Bimetallic dies with direct metal-deposited steel on Moldmax for high-pressure die casting application. Int J Adv Manuf Technol 52:855–863

Yao CW, Xu BS, Zhang XC, Huang J, Fu J, Wu YX (2009) Interface microstructure and mechanical properties of laser welding copper–steel dissimilar joint. Opt Lasers Eng 47:807–814

Lv SX, Song JL, Wang HT, Yang SQ (2009) Temperature field and flow field during tungsten inert gas bead welding of copper alloy onto steel. Mater Sci Eng A-Struct Mater 499:347–351

Yilmaz O, Celik H (2003) Electrical and thermal properties of the interface at diffusion-bonded and soldered 304 stainless steel and copper bimetal. J Mater Process Technol 141:67–76

Xiong BW, Cai CC, Wang H, Lu BP (2011) Fabrication of high chromium cast iron and medium carbon steel bimetal by liquid–solid casting in electromagnetic induction field. Mater Des 32:2978–2982

Durgutlu A, Okuyucu H, Gulenc B (2008) Investigation of effect of the stand-off distance on interface characteristics of explosively welded copper and stainless steel. Mater Des 29:1480–1484

Manesh HD, Taheri AK (2005) An investigation of deformation behavior and bonding strength of bimetal strip during rolling. Mech Mater 37:531–542

Krishna BV, Venugopal P, Rao KP (2005) Co-extrusion of dissimilar sintered P/M preforms—an explored route to produce bimetallic tubes. Mater Sci Eng A-Struct Mater 407:77–83

Martina F, Mehnen J, Williams SW, Colegrove P, Wang F (2012) Investigation of the benefits of plasma deposition for the additive layer manufacture of Ti–6Al–4V. J Mater Process Technol 212:1377–1386

Baufeld B, Van der Biest O, Gault R (2010) Additive manufacturing of Ti–6Al–4V components by shaped metal deposition: microstructure and mechanical properties. Mater Des 31:S106–S111

Wang FD, Williams S, Rush M (2011) Morphology investigation on direct current pulsed gas tungsten arc welded additive layer manufactured Ti6Al4V alloy. Int J Adv Manuf Technol 57:597–603

Clark D, Bache MR, Whittaker MT (2008) Shaped metal deposition of a nickel alloy for aero engine applications. J Mater Process Technol 203:439–448

Baufeld B, Van der Biest O, Gault R, Ridgway K (2011) Manufacturing Ti–6Al–4V components by shaped metal deposition: microstructure and mechanical properties. Trends in Aerospace Manufacturing 2009 International Conference, Sheffield, England

Baufeld B, Van der Biest O, Dillien S (2010) Texture and crystal orientation in Ti–6Al–4V builds fabricated by shaped metal deposition. Metall Mater Trans A 41A:1917–1927

Skiba T, Baufeld B, Van der Biest O (2011) Shaped metal deposition of 300M steel. Proc Inst Mech Eng B-J Eng Ma 225:831–839

Karunakaran KP, Suryakumar S, Pushpa V, Akula S (2009) Retrofitment of a CNC machine for hybrid layered manufacturing. Int J Adv Manuf Technol 45:690–703

Handbook ASM (1992) Properties and selection nonferrous alloys and special-purpose materials. vol. 2. ASM International, USA

Handbook ASM (1992) Alloy phase diagrams, vol 3. ASM International, USA

Zhao HH, Zhang GJ, Yin ZQ, Wu L (2011) A 3D dynamic analysis of thermal behavior during single-pass multi-layer weld-based rapid prototyping. J Mater Process Technol 211:488–495

Xiao WL, Jia SS, Wang J, Wu YM, Wang LM (2008) Effects of cerium on the microstructure and mechanical properties of Mg–20Zn–8Al alloy. Mater Sci Eng A-Struct Mater 474:317–322

Liu HM, Chen YG, Tang YB, Huang DM, Niu G (2006) The microstructure and mechanical properties of permanent-mould cast Mg–5 wt%Sn–(0–2.6) wt%Di alloys. Mater Sci Eng A-Struct Mater 437:348–355

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, L., Zhuang, Z., Liu, F. et al. Additive manufacturing of steel–bronze bimetal by shaped metal deposition: interface characteristics and tensile properties. Int J Adv Manuf Technol 69, 2131–2137 (2013). https://doi.org/10.1007/s00170-013-5191-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5191-7