Abstract

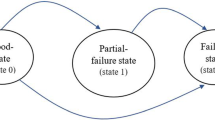

This research investigates the case of an unreliable manufacturing system subject to quality and reliability deterioration. In particular, we conjecture that the deterioration of the system leads to a continuous increase in the intensity of failures and a decrease on the quality of the parts produced. As such, deterioration implies a twofold effect on the manufacturing system. When the machine fails, minimal repair is conducted, leaving the machine at the same level of deterioration before failure. Hence, the quality of the parts produced and the failure intensity remain unchanged with this repair. Meanwhile, an overhaul refers to a perfect repair that completely restores the quality of the parts and the failure intensity of the machine. This option completely counters all the effects of the deterioration. Preventive maintenance may also be conducted, but it reduces the level of deterioration only partially, improving the quality of the units produced and the failure intensity just in part. This set of characteristics yields to the formulation of a new control model that simultaneously determines the optimal production plan, the overhaul, and preventive maintenance strategies. Such a joint control policy minimizes the total cost including the inventory holding, backlog, overhaul, preventive maintenance, and defective costs over an infinite planning horizon. Since the dynamics of the system change as a function of the level of deterioration, it is necessary to use its history for a proper formulation; therefore, a semi-Markov decision process is used. Numerical methods are applied to determine the control policy, and numerical examples are conducted as illustrations. An extensive sensitivity analysis is presented in order to confirm the structure of the control policy obtained and examine the effect of several parameters.

Similar content being viewed by others

References

Kimemia J, Gershwin S (1983) An algorithm for the computer control of production of a flexible manufacturing system. IIE Trans 51:191–2216, pp. 628–633

Akella R, Kumar PR (1986) Optimal control of production rate in a failure prone manufacturing system. IEEE Trans Autom Control AC-31:116–126

Mok PY, Porter B (2005) Evolutionary optimization of hedging points for unreliable manufacturing systems. Int J Adv Manuf Technol 28:205–214

Sajadi SM, Seyed Esfahani MM, Sörensen K (2011) Production control in a failure-prone manufacturing network using discrete event simulation and automated response surface methodology. Int J Adv Manuf Technol 53:35–46

Gharbi A, Hajji A, Dhouib K (2011) Production rate control of an unreliable manufacturing cell with adjustable capacity. Int J Prod Res 49(21):6539–6557

Inman RR, Blumenfeld DE, Huang N (2003) Designing production systems for quality: research opportunities from an automotive industry perspective. Int J Prod Res 41(9):1953–1971

Tempelmeier H, Bürger M (2001) Performance evaluation of unbalanced flow lines with general distributed processing times, failures and imperfect production. IIE Trans 33:293–302

Kim J, Gershwin S (2008) Analysis of long flow lines with quality and operational failures. IIE Trans 40:284–296

Kim J, Gershwin S (2005) Integrated quality and quantity modeling of a production line. OR Spectr 27:287–314

Colledani M, Tolio T (2009) Performance evaluation of production systems monitored by statistical process control and off-line inspections. Int J Econ 120:348–367

Colledani M, Tolio T (2011) Integrated analysis of quality and production logistics performance in manufacturing lines. Int J Prod Res 49(2):485–518

Mhada F, Hajji A, Malhame R, Gharbi A, Pellerin R (2011) Production control of unreliable manufacturing systems producing defective items. J Qual Maint Eng 17(3):238–253

Hajji A, Gharbi A, Pellerin R (2012) Joint production control and product quality decision making in a failure prone multiple-product manufacturing system. Int J Prod Res 50(13):3661–3672

Lam Y, Zhu LX, Chan JSK, Liu Q (2004) Analysis of data from a series of events by a geometric process model. Acta Mathematicae Applicatae 20:263–282

Wu S, Clements-Croome D (2006) A novel repair model for imperfect maintenance. IMA J Manag Math 17:235–243

Lai MT, Chen YC (2006) Optimal periodic replacement policy for a two-unit system with failure rate interaction. Int J Adv Manuf Technol 29:367–371

Dehayem Nodem FI, Kenné JP, Gharbi A (2011) Production planning and repair/replacement switching policy for deteriorating manufacturing systems. Int J Adv Manuf Technol 57:827–840

Yulan J, Zuhua J, Wenrui H (2008) Multi-objective integrated optimization research on preventive maintenance planning and production scheduling for a single machine. Int J Adv Manuf Technol 39:954–964

Radhoui M, Rezg N, Chelbi A (2010) Integrated maintenance and control policy based on quality control. Comput Ind Eng 48:443–451

Dhouib K, Gharbi A, Ben Aziza MN (2012) Joint optimal production control/preventive maintenance policy for imperfect process manufacturing cell. Int J Prod Econ 137:126–136

Rivera-Gomez H, Gharbi A, Kenné JP (2013) Production and quality control policies for deteriorating manufacturing system. Int J Prod Res 51:3443–3462

Gershwin SB (2002) Manufacturing systems engineering. Massachusetts Institute of Technology, Cambridge, Second private printing

Love CE, Zhang ZG, Zitron MA, Guo R (2000) A discrete semi-Markov decision model to determine the optimal repair/replacement policy under general repairs. Eur J Oper Res 125:398–409

Boukas EK, Hauire A (1990) Manufacturing flow control and preventive maintenance: a stochastic control approach. IEEE Trans Autom Control 33:1024–1031

Kenne JP, Gharbi A (1999) Experimental design in production and maintenance control problem of a single machine, single product manufacturing system. Int J Prod Res 37(3):621–637

Gharbi A, Kenne JP (2005) Maintenance scheduling and production control of multiple-machine manufacturing systems. Comput Ind Eng 48(4):693–707

Doyen L, Gaudoin O (2004) Classes of imperfect repair models based on reduction of failure intensity or virtual age. Reliab Eng Syst Saf 84:45–46

Kushner HJ, Dupuis PG (1992) Numerical methods for stochastic control problems in continuous time. Springer, New York

Kenné JP, Boukas EK, Gharbi A (2003) Control of production and corrective maintenance rates in a multiple-machine, multiple-product manufacturing system. Math Comput Model Pergamon 38:351–365

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivera-Gomez, H., Gharbi, A. & Kenné, J.P. Joint control of production, overhaul, and preventive maintenance for a production system subject to quality and reliability deteriorations. Int J Adv Manuf Technol 69, 2111–2130 (2013). https://doi.org/10.1007/s00170-013-5183-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5183-7