Abstract

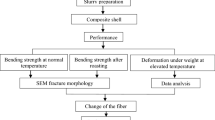

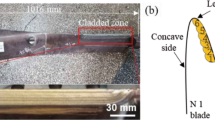

The development of hollow turbine blades fabricated by nickel-base superalloy is limited by its high density and low operating temperature (<1,100 °C). A new technology for fabricating hollow turbine blades of fiber-reinforced SiC composite was put forward. The chemical corrosion process of DSM Somos 19120 resin mold was investigated, and the pyrolysis of phenolic resin and the infiltration of liquid silicon were analyzed by using scanning electron microscope and X-ray diffraction. The influence of carbon fiber content on fracture strength and fracture toughness of fiber-reinforced SiC composite was investigated using the measurement of three-point flexural strength test. Results showed that stereolithography molds of photosensitive resin were corroded perfectly using KOH alcohol water solution. The porous carbon preforms were obtained after phenolic resin was pyrolyzed from 400 to 800 °C, which were then infiltrated with molten silicon to gain SiC matrix at the temperature of 1,450 °C in 1 h. The fracture strength and fracture toughness of SiC ceramic matrix were enhanced with the increase of short carbon fiber content. The maximum fracture strength and fracture toughness of samples were about 270 MPa and 5.1 MPa m1/2, respectively. Finally, hollow turbine blades were successfully fabricated using short carbon fiber-reinforced SiC composite.

Similar content being viewed by others

References

Chen XJ, Li DC, Wu HH et al (2012) Analysis of ceramic shell cracking in stereolithography-based rapid casting of turbine blade. Int J Adv Manuf Tech 55(5–8):447–455

Islami SB, Jubran BA (2012) The effect of turbulence intensity on film cooling of gas turbine blade from trenched shaped holes. Heat Mass Transfer 48(5):831–840

Wu HH, Li DC, Chen XJ et al (2010) Rapid casting of turbine blades with abnormal film cooling holes using integral ceramic casting molds. Int J Adv Manuf Tech 50(1–4):13–19

Belyakov AV, Razumnova IV, Demonis IM (2012) Easily removed ceramic rods for casting gas-turbine engine blades using molding patterns. Glass Ceram 69(3–4):125–129

Lee JS, Yano T (2004) Fabrication of short-fiber-reinforced SiC composites by polycarbosilane infiltration. J Eur Ceram Soc 24:25–31

Zhuan L, Peng X, Xiong X, Huang BY (2012) Preparation and tribological properties of C fiber reinforced C/SiC dual matrix composites fabrication by liquid silicon infiltration. Solid State Sci. doi:10.1016/j.solidstatesciences.2012.10.007

Magnant J, Maillé L, Pailler R et al (2012) Carbon fiber/reaction-bonded carbide matrix for composite materials—manufacture and characterization. J Eur Ceram Soc 32:4497–4505

Ji RJ, Liu YH, Zhang YZ (2012) Influence of dielectric and machining parameters on the process performance for electric discharge milling of SiC ceramic. Int J Adv Manuf Tech 59(1–4):127–136

Safi S, Rad RY (2012) In situ synthesis of nano size silicon carbide and fabrication of C–SiC composites during the siliconization process of mesocarbon microbeads performs. Ceram Int 38:5081–5087

Esfehanian M, Günster J, Moztarzadeh F, Heinrich JG (2007) Development of a high temperature Cf/XSi2–SiC (X = Mo, Ti) composite via reactive melt infiltration. J Eur Ceram Soc 27:1229–1235

Lee JS, Imai M, Yano T (2003) Fabrication and mechanical properties of oriented SiC short-fiber-reinforced SiC composite by tape casting. Mat Sci Eng A 339:90–95

Yang WS, Fuso L, Biamino S, Vasquez D et al (2012) Fabrication of short carbon fibre reinforced SiC multilayer composites by tape casting. Ceram Int 38:1011–1018

Wang YX, Tan SH, Jiang DL (2004) The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC. Carbon 42:1833–1839

Jiang GP, Yang J, Xu YD, Gao JQ et al (2008) Effect of graphitization on microstructure and tribological properties of C/SiC composites prepared by reactive melt infiltration. Compos Sci Technol 68:2468–2473

Tian XY, Zhang WG, Li DC, Jürgen GH (2012) Reaction-bonded SiC derived from resin precursors by stereolithography. Ceram Int 38:589–597

Ding YS, Dong SM, Huang ZR, Jiang DL (2007) Fabrication of short C fiber-reinforced SiC composites by spark plasma sintering. Ceram Int 33:101–105

Tanaka Y, Kagawa Y, Liu YF, Masuda C (2001) Interface damage mechanism during high temperature fatigue test in SiC fiber-reinforced Ti alloy matrix composite. Mat Sci Eng A 314:110–117

Guo S, Naito K, Kagawa Y (2012) Mechanical and physical behaviors of short pitch-based carbon fiber-reinforced HfB2-SiC matrix composites. Ceram Int 39(2):1567–1574. doi:10.1016/j.ceramint.2012.07.108

Xu SJ, Qiao GJ, Wang HJ, Li DC, Lu TJ (2009) Microstructure evolution and reaction mechanism of microporous carbon derived SiC ceramics. J Inorg Mater 24(2):291–296

Xu SJ, Qiao GJ, Li DC, Yang H, Liu YN, Lu TJ (2009) Reaction forming of silicon carbide ceramic using phenolic resin derived porous carbon perform. J Eur Ceram Soc 29:2395–2402

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Z.L., Lu, F., Cao, J.W. et al. Fabricating hollow turbine blades using short carbon fiber-reinforced SiC composite. Int J Adv Manuf Technol 69, 417–425 (2013). https://doi.org/10.1007/s00170-013-5049-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5049-z